Converter bottom blowing air brick, special drilling machine and quick thermal replacement method of air brick

A technology of converter bottom blowing and air-permeable bricks, which is applied in the manufacture of converters, etc. It can solve the problems of chemical corrosion of refractory materials, inability to synchronize furnace ages, and damage to protective sleeve bricks, and achieve good high-temperature strength and thermal shock resistance. Replacement time and cost saving effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

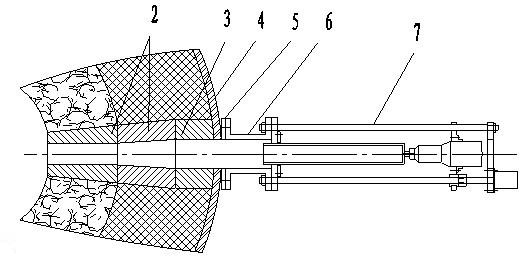

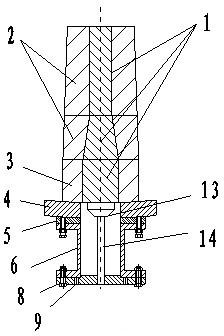

[0039] The converter bottom air-blowing brick of the present invention comprises a breathable core brick 1 , a protective sheath brick 2 , a furnace bottom flange 5 and a cylinder flange 6 .

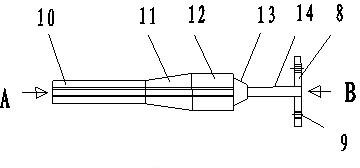

[0040] As shown in the figure, the air-permeable core brick 1 of the present invention is a three-stage air-permeable core brick suitable for rapid thermal replacement. The outer dimension is: diameter * length = Φ (80 ~ 150) * (400 ~ 800) mm, the cylinder can be matched with the sleeve type drill bit, and the holes required by the smaller diameter are easy to drill through. (2) The middle section 11 is a quick-change section, which is a frustum of conical body with a large taper. 300) mm, during hot replacement, the residual bricks of this frustum of cone can be easily pulled out, and no drilling is required here, and the damage to this place is small when drilling the residual bricks or slag layer in the upper section, which is beneficial to protect the lower Set of bricks. (3) The low...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com