Wound steel rope replacing method

A replacement method and wire rope technology, applied in the direction of the hoisting device, the mechanism of the mainspring, etc., can solve the problems of complicated operation, and achieve the effect of simplifying the replacement operation, saving the replacement time, and reducing the number of operators.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the accompanying drawings.

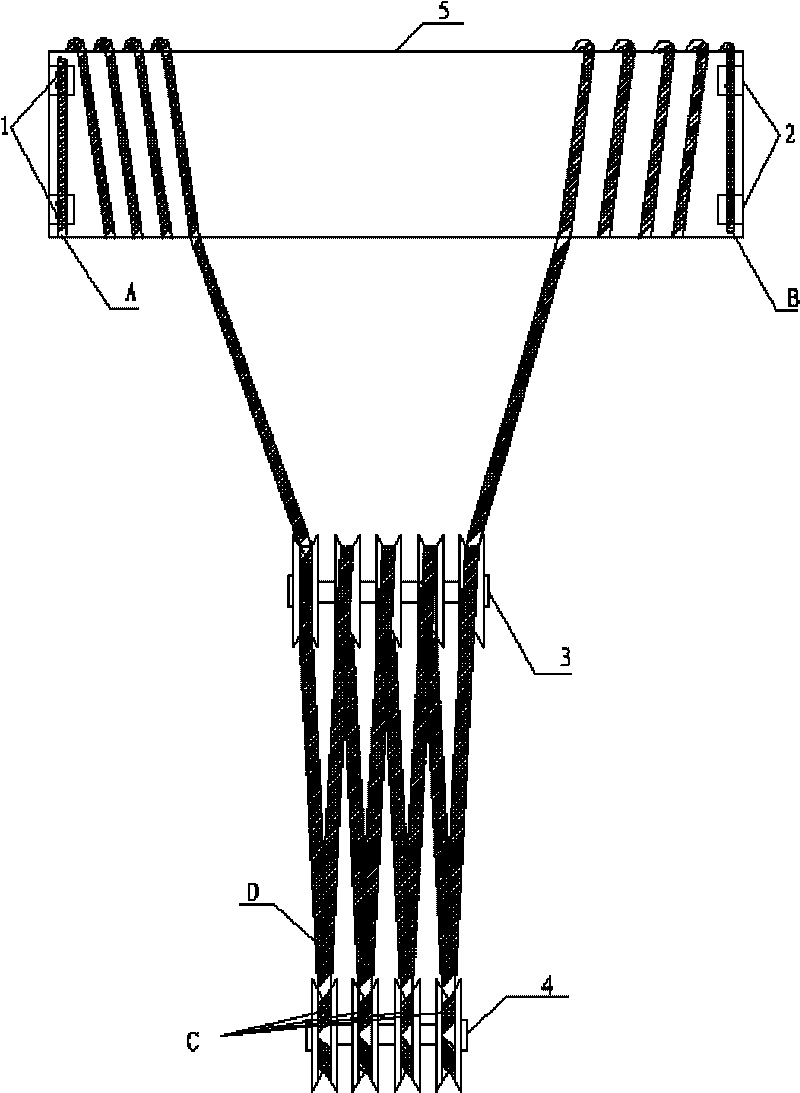

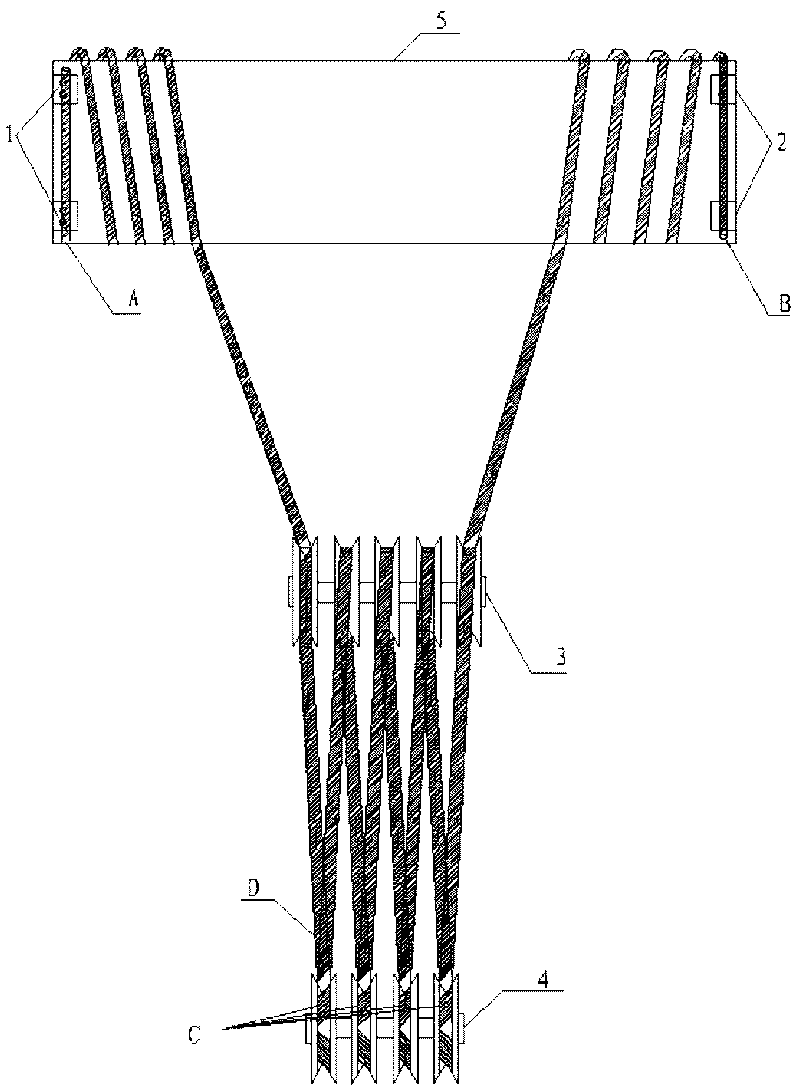

[0018] Such as figure 1 As shown, the winding wire rope replacement method of the present invention comprises the following steps,

[0019] Preparation: Lower the movable pulley block 4 of the wire rope winding system to the ground, place it in the wire rope replacement operation area, and remove the limit switch on the reel 5;

[0020] Cutting: first put down all the old steel wire ropes wound on the reel 5 until only the end of the old steel wire rope pressed by the pressure plate is on the reel 5, take a point on the outermost wire rope on the side of the first pressure plate 1 and cut it off with a torch For the old steel wire rope, loosen the first pressing plate 1 on the cut side reel 5, and remove the old steel wire rope between the cutting point D of the steel rope and the first pressing plate 1;

[0021] Connection: use a cutting torch to carry out full weld...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com