Anti-clogging clay pipe packing subsurface flow constructed wetland

An artificial wetland and anti-clogging technology, applied in chemical instruments and methods, water/sludge/sewage treatment, biological water/sewage treatment, etc., can solve problems such as limited sewage treatment capacity, easy breeding of mosquitoes, and decline in wetland functions , to achieve efficient sewage treatment capacity, improve sewage treatment efficiency, and large specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

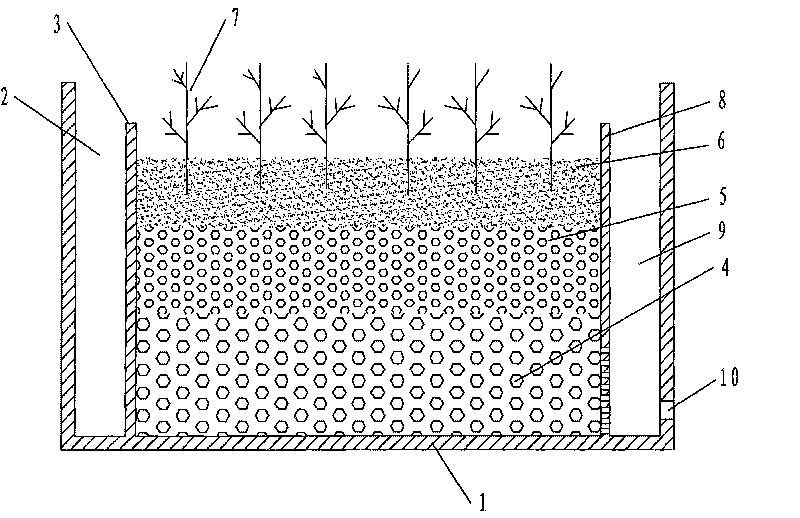

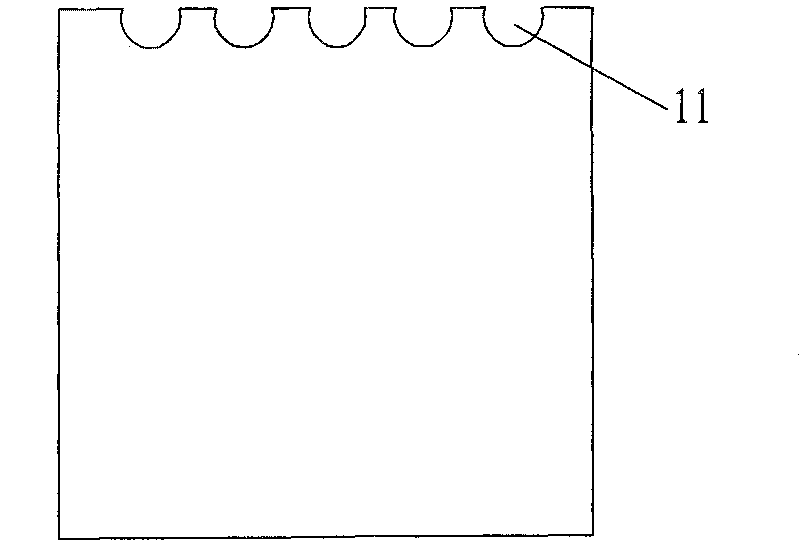

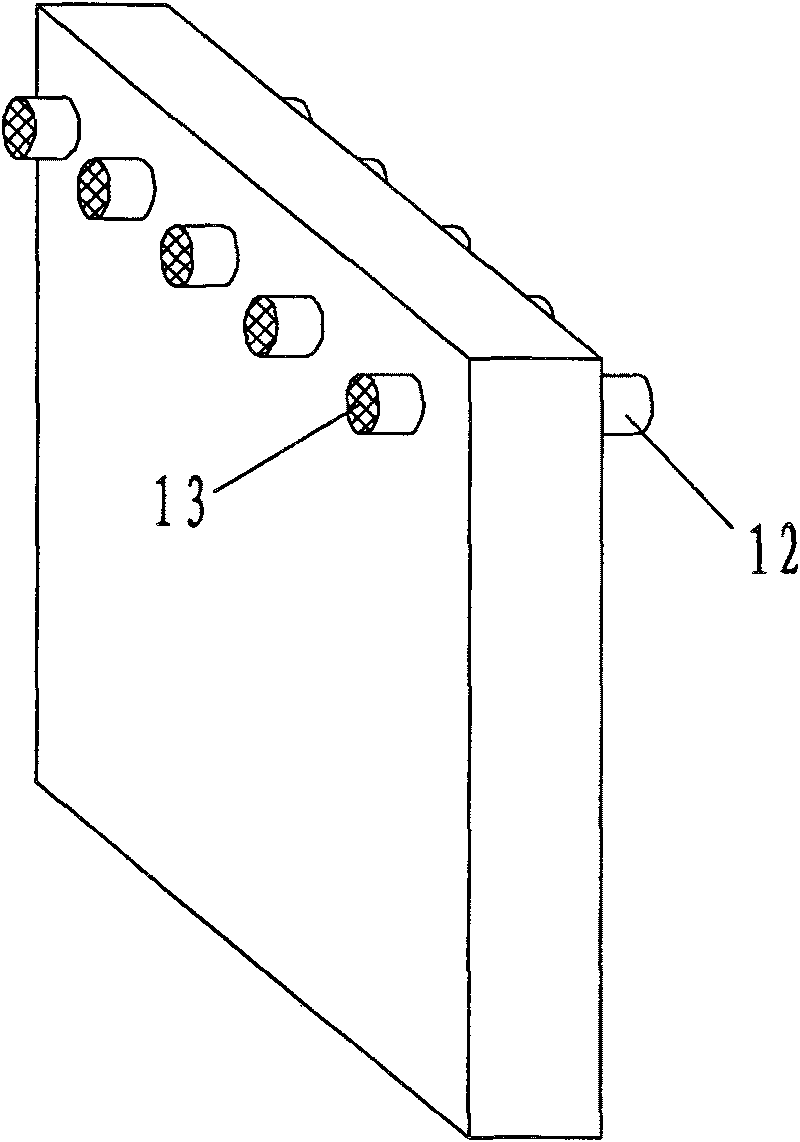

[0017] Such as figure 1 As shown, the present invention mainly includes a wetland main body 1, a water storage tank 2, a water distribution plate 3, a large pottery pipe packing layer 4, a small pottery pipe packing layer 5, a soil packing layer 6, wetland plants 7, a water retaining plate 8 and a water storage pool9. The wetland main body 1 is made of cement and bricks, and the bottom is treated with anti-seepage to prevent sewage from penetrating and polluting groundwater. The inner left side of wetland main body 1 (with figure 1 Shown position judgment) is provided with water distributing plate 3, and the right side is provided with water retaining plate 8. The space between the left side wall of the wetland main body 1 and the water distribution plate 3 forms a water storage tank 2 , and the space between the right side wall and the water retaining plate 8 forms a water storage tank 9 . The structure of the water distribution board 3 is as figure 2 , The top is provid...

Embodiment 2

[0020] This embodiment is basically the same as Embodiment 1 in terms of wetland composition, the difference being the filler layer. The filler layer in this embodiment is also divided into three layers. The bottom filler is a large pottery pipe with a thickness of 50 cm, and the middle layer is laid with vermiculite with a thickness of 30 cm; the upper layer The filler is pastoral soil with a thickness of 20cm.

Embodiment 3

[0022] This embodiment is basically the same as Embodiment 1 in terms of wetland composition, the difference being the packing layer. The packing layer in this embodiment is also divided into three layers. The bottom packing is a large pottery pipe with a thickness of 50 cm, and the middle packing is gravel with a thickness of 20 cm; the upper layer The filler is pastoral soil with a thickness of 30cm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com