Chain saw guide plate

A chain saw guide plate and guide plate technology, which is applied in the direction of sawing machine devices, metal sawing equipment, sawing machine accessories, etc., can solve the problems of friction, heat and easy wear, and affect the service life of guide plates and chains, so as to improve life, eliminate impurities, The effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

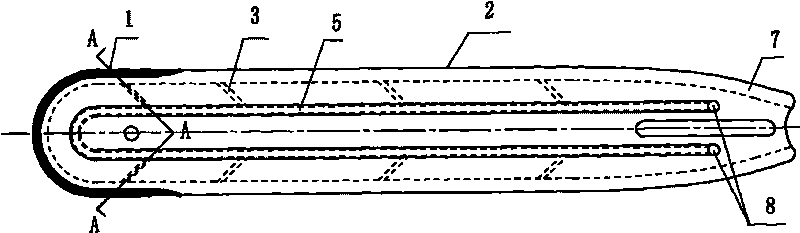

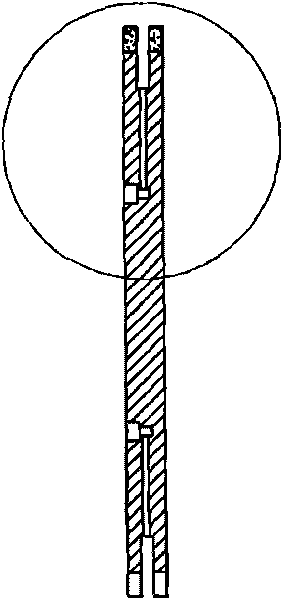

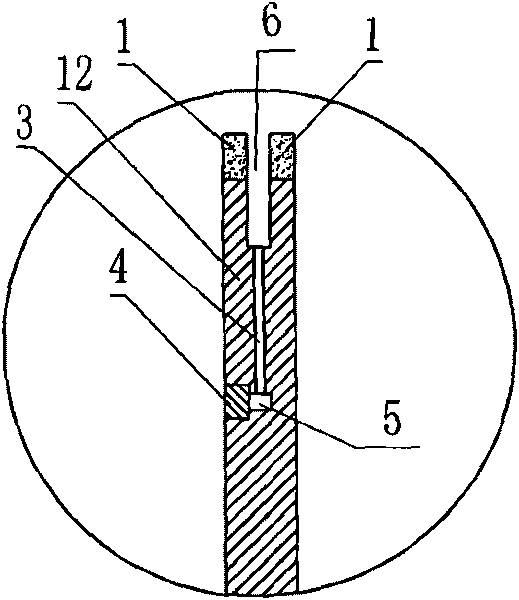

[0032] Embodiments of the present invention are described in detail below in conjunction with the accompanying drawings:

[0033] The chain saw guide plate of the present invention is composed of a guide plate body 2, a chain guide device, a chain guide groove 6 and a cooling water delivery channel. The cooling water delivery channel is suitable for any kind of guide plate. The chain groove 6 is conducive to cooling the object to be cut and the chain saw chain, improving the heat dissipation capacity and chip removal capacity of the guide plate, and at the same time humidifying the cutting dust, improving the working environment, reducing the wear of the guide plate and chain, and improving the wear resistance of the guide plate. life. The cooling water delivery channel of the chainsaw guide plate of the present invention has the following three structures.

[0034] The first type is a water channel 5 arranged on the surface of the guide plate body 2 , and its water inlet end...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com