Method for increasing constructional column for brick masonry wall

A technology for constructing columns and body walls, which is applied to building structures, building components, and earthquake resistance. The effect of good performance, reinforcement effect and good bonding performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

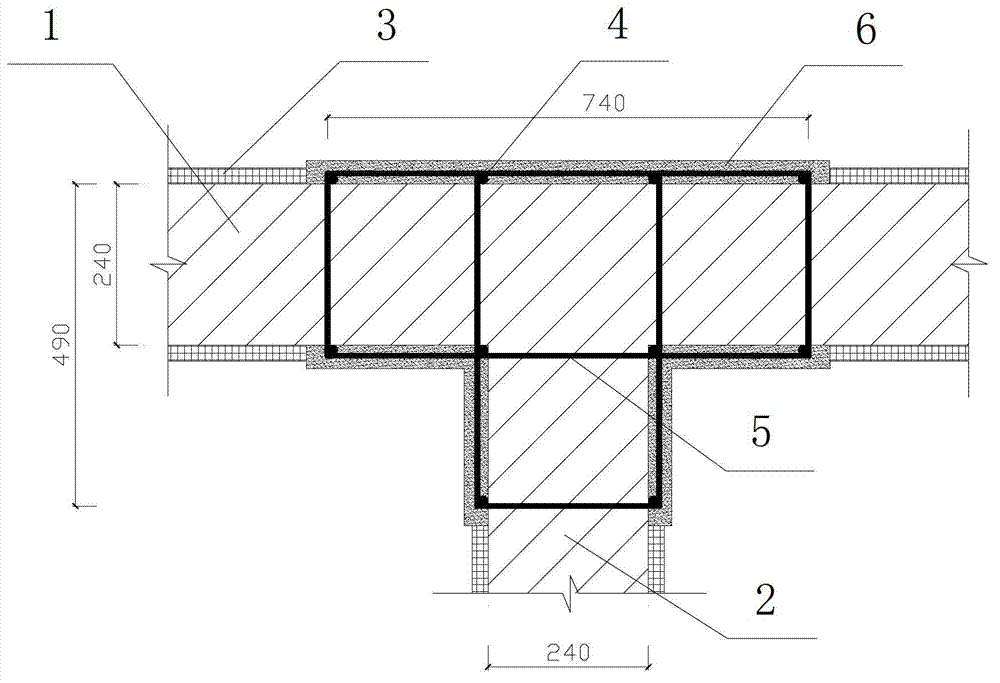

[0030] Follow the technical scheme of the present invention, such as figure 1 and figure 2 As shown, the building to be reinforced in this embodiment is a four-story brick-concrete structure office building, the brick masonry wall thickness is 240 mm, and the seismic fortification intensity is 7 degrees. Add a structural column at the junction of the vertical and horizontal walls in the middle of the house. The size of the structural column is to extend one brick length vertically and horizontally at the junction of the vertical and horizontal walls (1, 2), which is 240mm, which is determined as the size range of the pre-added structural column. , first pre-treat the surface of the brick masonry wall, remove the original mortar surface layer 3 and perform surface cleaning; then arrange longitudinal steel bars with a diameter of 12mm at the corners of the wall at the intersection of vertical and horizontal walls and at the corners of pre-added structural columns 4. A total of...

Embodiment 2

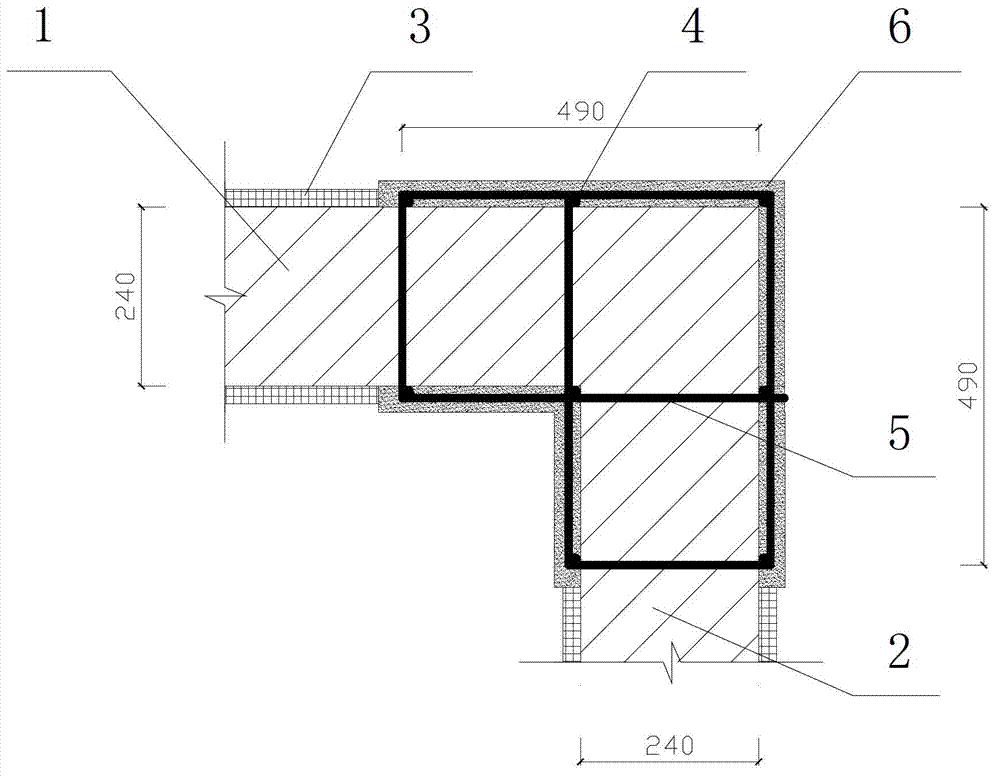

[0041] This embodiment is a six-storey brick-concrete structure office building, the brick masonry wall thickness is 240mm, the seismic fortification intensity is 8 degrees, and structural columns are added at the intersection of vertical and horizontal walls at the corners of the building. The size of the structural column is still 240mm long extending one brick vertically and horizontally at the junction of the vertical and horizontal walls. This example differs from Embodiment 1 in that the additional structural column is a corner column, and the additional structural column has a different shape, and the arranged longitudinal reinforcement 4 is eight steel bars with a diameter of 14mm. The structural form of the rectangular closed stirrup 5 is as follows Figure 4 As shown, the stirrup 5 spacing is 200mm. Other construction procedures are all the same as in Example 1.

[0042] The invention not only improves the shear strength and anti-seismic ability of the brick masonry...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com