Pre-installation construction method for wire box on building bricked body and pre-installation supporting frame thereof

A technology of pre-installation and building bricks, which is applied in the direction of construction, building structure, and building materials processing, etc., can solve problems such as damage to the health of operators, unfavorable civilized construction management, and impact on the quality of wall structures, so as to achieve environmental benefits Protection, beneficial to civilized construction management, beneficial to the effect of health

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention will be further described below in combination with specific embodiments and accompanying drawings.

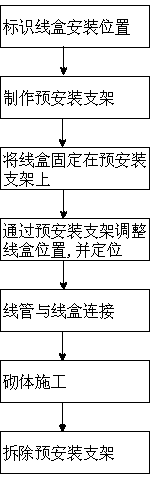

[0043] Such as Figure 1 to Figure 9 As shown, a construction method for pre-installation of a building brick masonry wiring box includes the following steps:

[0044] one. Before the wall is built, the installation position of the wire box is determined according to the wall axis and elevation, and marked;

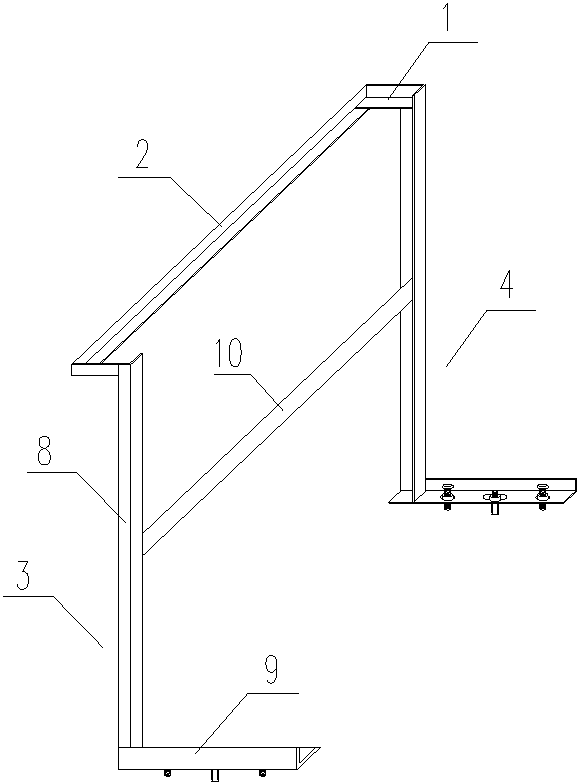

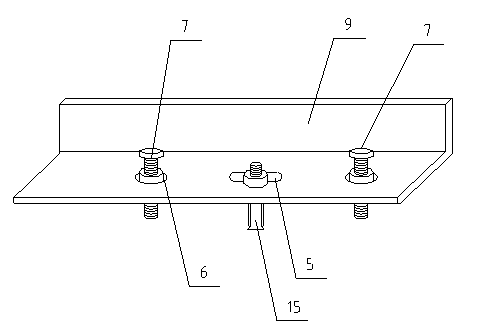

[0045] two. Make pre-installation support, this pre-installation support comprises first support frame 3, second support frame 4, connecting rod 1 and horizontal support bar 2, and described first support frame 3 and second support frame 4 are all formed by vertical bar 8 and Bottom rod 9 is composed of vertical rod 8 vertically fixed on one end of bottom rod 9, and the two ends of horizontal support rod 2 are vertically connected with the top of vertical rod 8 through connecting rod 1. The bottom rod 9 is provided with strips along the len...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com