Base module, assembly, preparation die, and construction method for ceramic brick masonry wall

A basic module and ceramic brick technology, applied in the field of building exterior walls, can solve the problems of inconvenient inspection, combined device conduction temperature, inconvenient handling and circulation, etc., and achieve the effect of saving manpower, ensuring construction quality, and rapid construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] In the following, the technical means adopted by the present invention to achieve the intended purpose of the invention will be further described in conjunction with the accompanying drawings and preferred embodiments of the present invention.

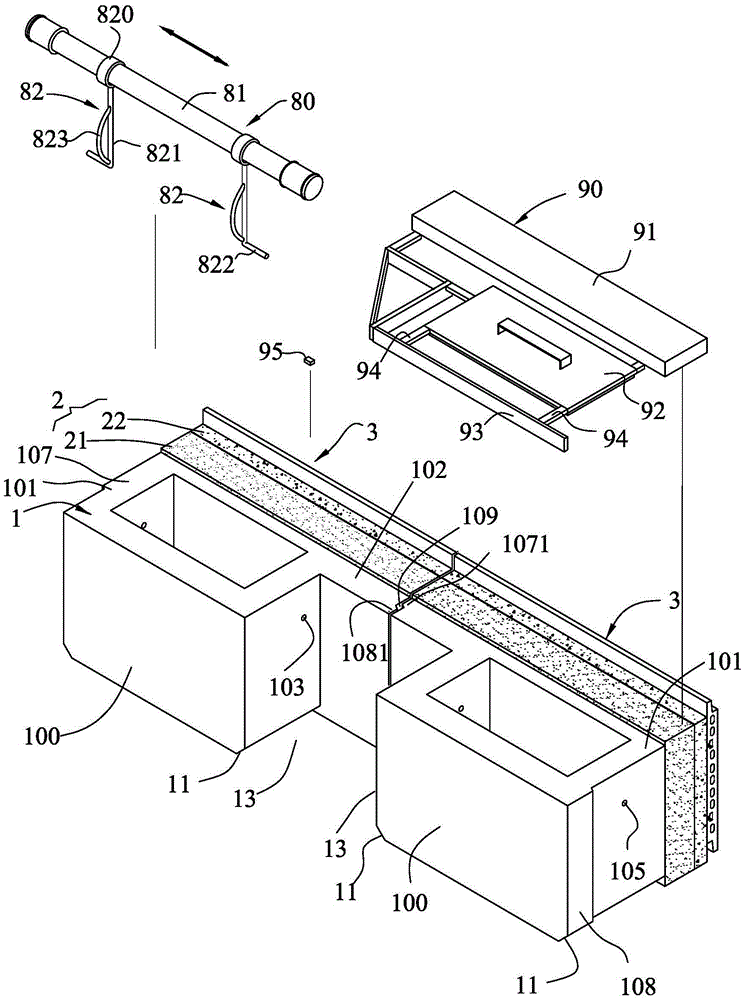

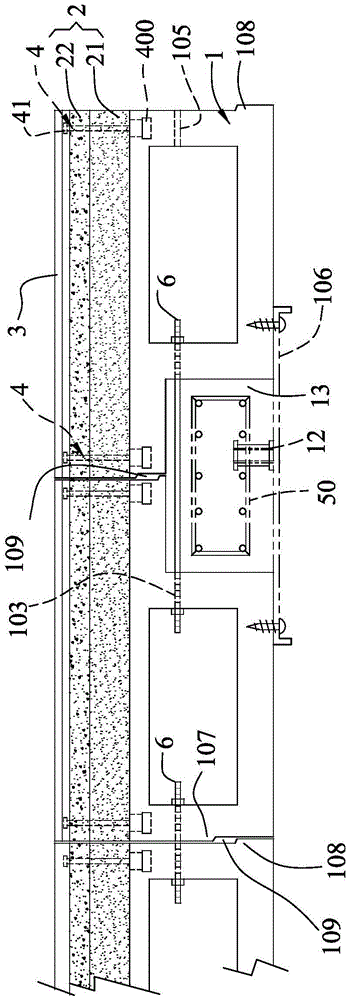

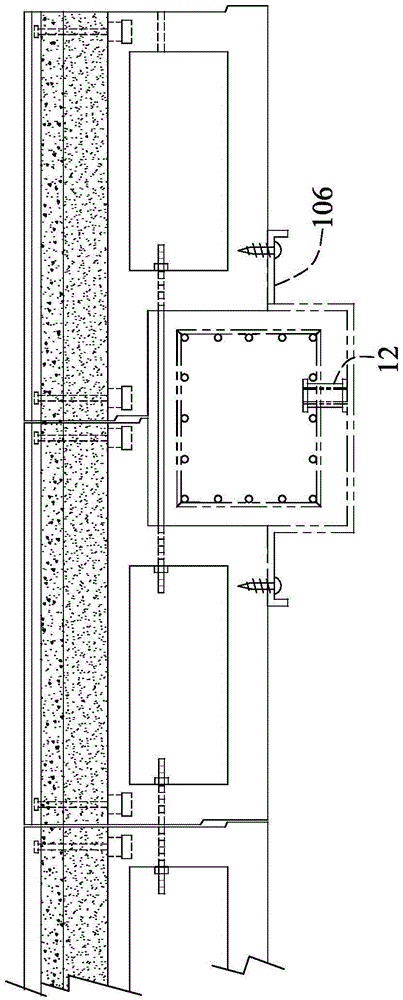

[0040] Please refer to figure 1 , 2 As shown, the pottery brick and stone wall assembly provided by the present invention includes a pottery brick block 1, a thermal insulation unit 2, an exterior trim panel 3, and a plurality of broken bridge coupling devices 4, through which the multiple broken bridge coupling devices 4 can be The pottery brick block 1, the thermal insulation unit 2 and the exterior trim board 3 are assembled into an inseparable pottery brick and stone wall assembly. For the convenience of description, in the following description, the side with the exterior trim panel 3 is defined as the exterior wall side, the opposite side facing the interior of the building is defined as the interior wall side, and the le...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com