Heat-preserving energy-saving wall structure

A technology of wall structure and thermal insulation layer, applied in thermal insulation, wall, building components and other directions, can solve the problems of insufficient strength, high cost, affecting thermal insulation effect, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

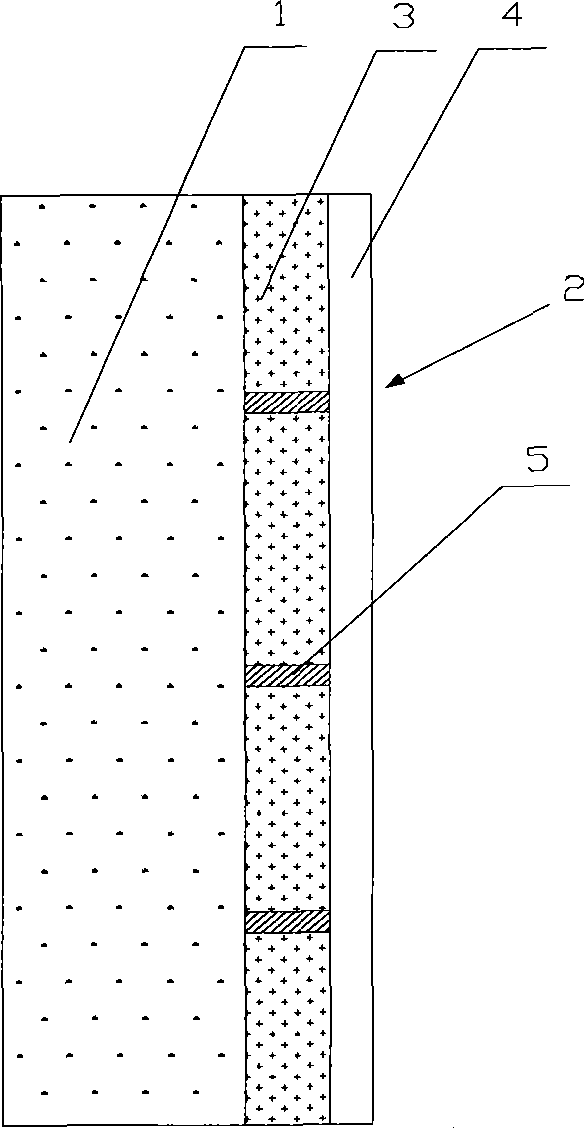

[0016] Such as figure 1 As shown, the present invention is made up of brick masonry layer 1 and insulation layer 2, and described insulation layer 2 is formed by the combination of insulation material layer 3 and OSB board 4, and insulation layer 2 is insulation material layer 3, OSB board respectively from inside to outside. plate 4. The thermal insulation material layer 3 is fixed on the masonry layer 1 with a wooden strip 5 as a keel, and is formed on the wall surface of the masonry layer 1 such as Figure 4 In the lattice shape shown, the insulation material is filled in the lattice between the wooden strips 5 . The insulation material in the warm material layer 3 is an extruded polystyrene foam product.

Embodiment 2

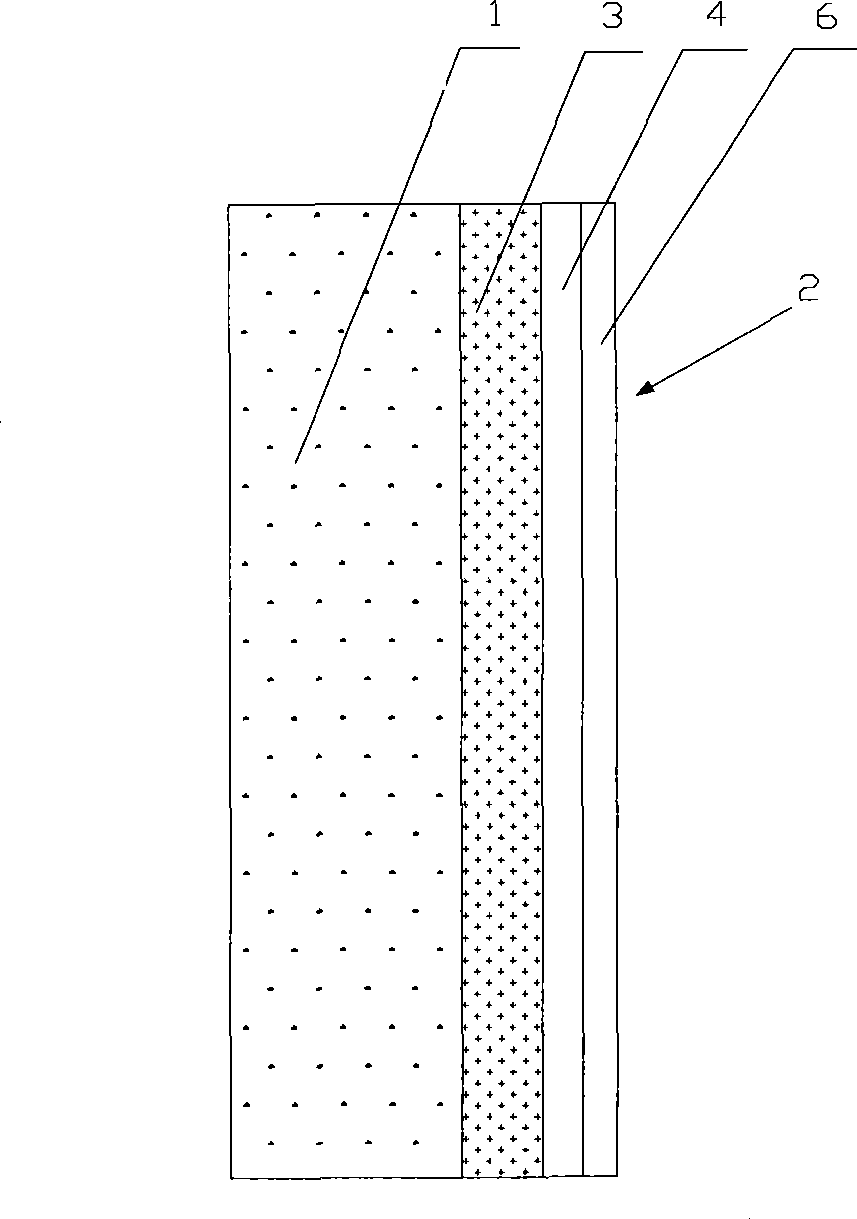

[0018] Such as figure 2 As shown, it is another solution of the present invention, the insulation material layer 3 is directly bonded on the OSB board 4, and fixed on the masonry layer 1 by bolts. The insulation material in the warm material layer 3 is a calcium plastic product.

Embodiment 3

[0020] Such as image 3 As shown, in order to further improve the waterproof performance of the wall, an exterior wall decoration layer 6 is formed outside the insulation layer 2 on the exterior wall surface, and the exterior wall decoration layer 6 is made of waterproof material. The thermal insulation material in the thermal material layer 3 is an expanded perlite product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com