Method for increasing ring beam for brick masonry wall

A brick masonry and body wall technology, which is applied in the direction of building components, earthquake resistance, construction, etc., can solve the problems of complex construction technology, limited improvement of ductility after reinforcement, and influence on the appearance of buildings, so as to avoid local crushing and improve the overall Good anti-seismic performance and reinforcement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

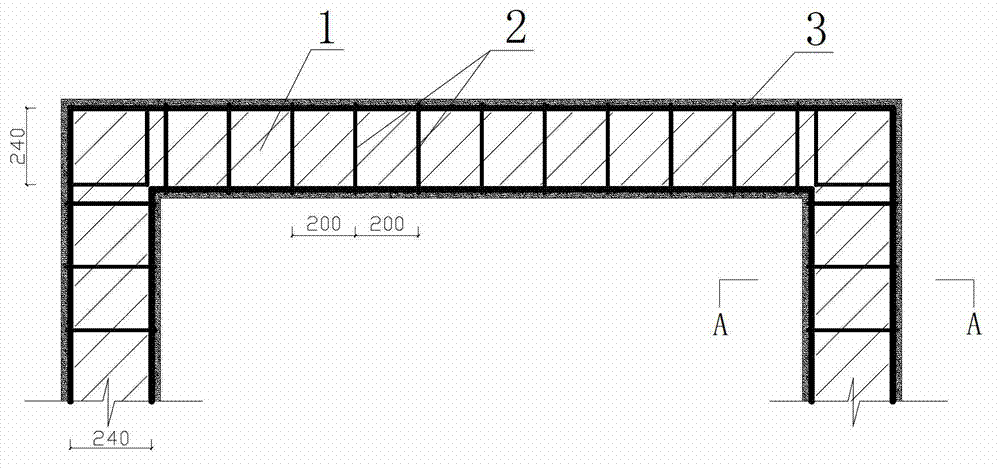

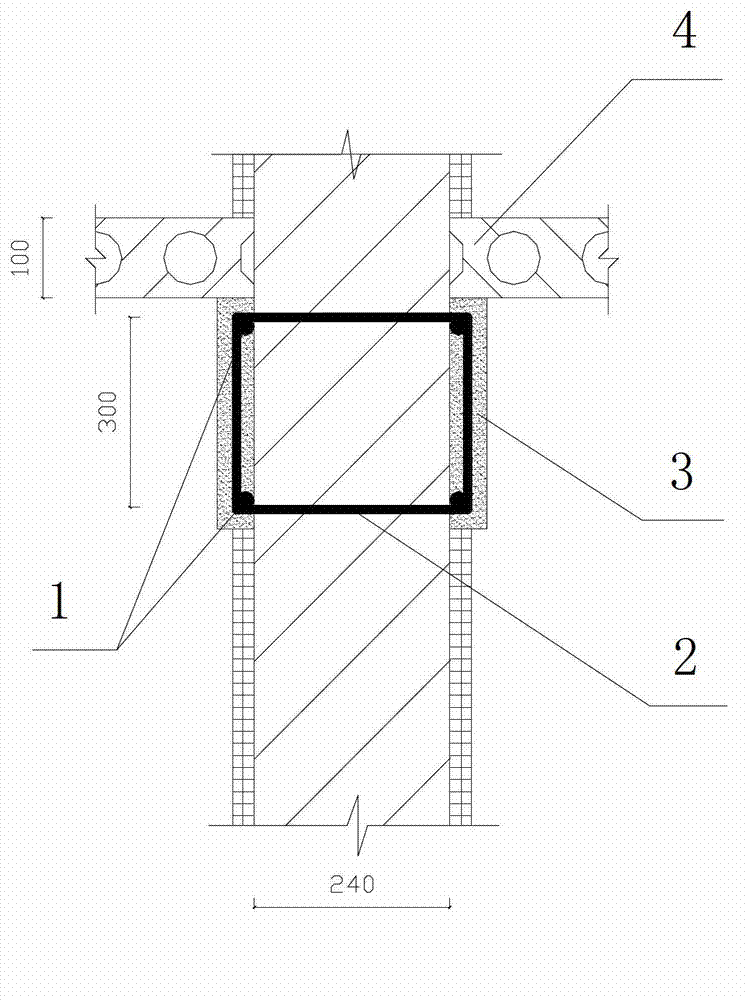

[0029] Follow the technical scheme of the present invention, such as figure 1 and figure 2 As shown, this embodiment is a six-storey brick-concrete office building, the thickness of the brick wall is 240mm, and the seismic fortification intensity is 8 degrees. Add a ring beam under the floor 4 of the brick masonry structure. The height of the pre-added ring beam is 240mm, and the width is the same as the wall thickness of 240mm. At the same time, the surface of the brick masonry wall where the ring beam is pre-installed is pretreated to remove the original mortar surface and surface cleaning; then arrange longitudinal steel bars 1 along the upper and lower edges of both sides of the wall at the pre-added ring beam respectively; then drill holes in the horizontal mortar joints of the wall every 200mm along the longitudinal direction of the pre-added ring beam and bind them Stirrups 2; finally, 30mm thick high ductility fiber concrete is applied on the surface of the wall wher...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com