High-temperature resistant expansion joint for dry quenching

A technology of high temperature resistant and expansion joints, which is applied in the field of CDQ high temperature resistant expansion joints, can solve the problems of easily damaged refractory materials and expansion joint structures, affecting the stable operation of CDQ system, and easy aging of refractory materials, so as to improve the connection Improve strength, shorten maintenance and replacement time, and ensure the effect of fire resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

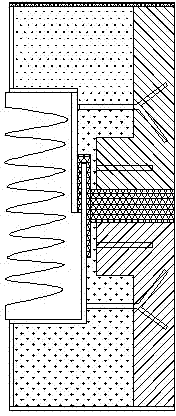

[0020] Such as figure 1 and 2 In the existing high-temperature expansion joint shown, the vault and the side wall are connected into one body by pouring. If the vault or the side wall is damaged separately, it can only be repaired as a whole, and the maintenance time is greatly increased. At the same time, the side wall needs to pour the refractory layer and the insulation layer in parts, and the connecting pins must be embedded between the refractory layer and the insulation layer. The process is complicated and time-consuming.

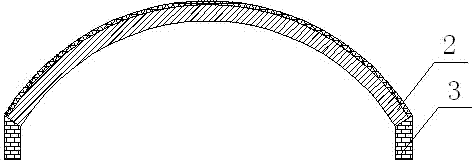

[0021] Such as Figures 2 to 4 The high-temperature expansion joint of the present invention shown is divided into a side wall 1, a vault 2 and a corner 3, and the corner 3 splices the side wall 1 and the vault 2 into one; Wall refractory layer 4, side wall insulation layer 5 and side wall labyrinth layer 6; said vault 2 is from inside to outside vault refractory layer 7, vault insulation layer 8, vault crimping layer 9 and particle backfill layer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com