Multilayer brick mixed thermal insulation wall and construction method thereof

A technology for thermal insulation walls and construction methods, which is applied to walls, building components, buildings, etc., can solve the problems of complex construction procedures, large material usage, and high cost of thermal insulation walls, and can meet the requirements of thermal insulation effects, simple construction methods, and high cost. The effect of reducing cracking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

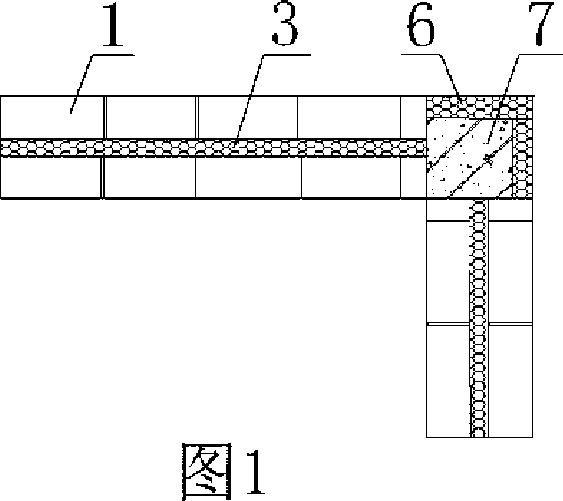

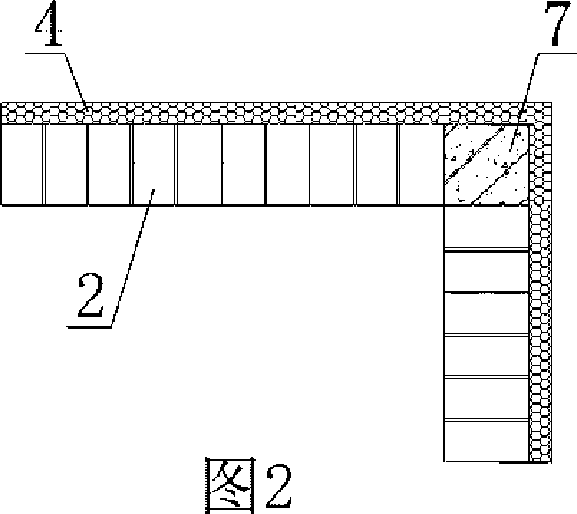

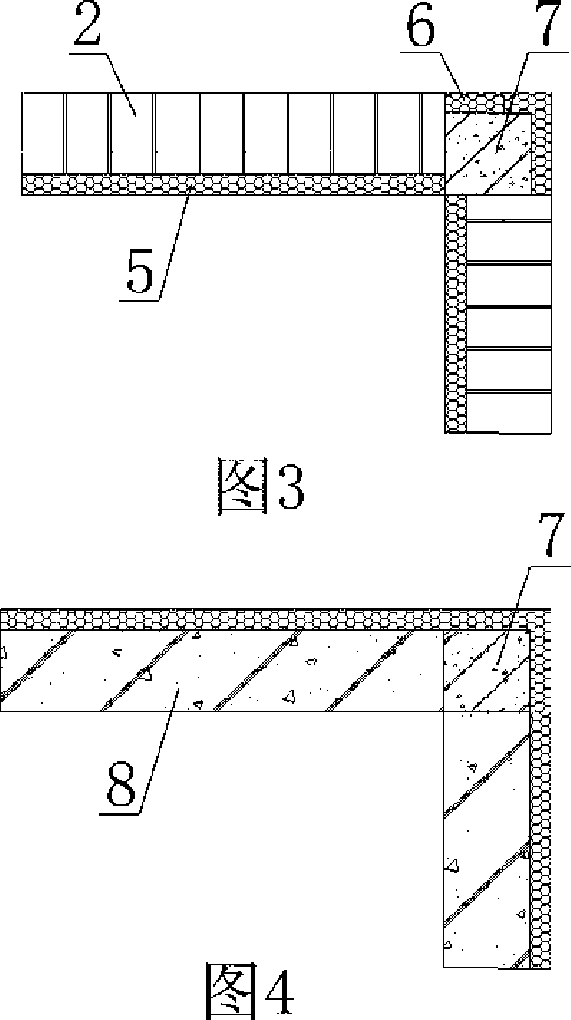

[0030] See Figure 1- Figure 5 As shown, this multi-layer brick-concrete thermal insulation wall is a brick-concrete structure, and the brick masonry is connected with the reinforced concrete structural column 7 at the corner. It is characterized in that: the thermal insulation wall is the following three-layer brick masonry Combined circular masonry from bottom to top, the thermal insulation layer in the brick masonry is arranged staggeredly in a sequence of middle thermal insulation layer 3, outer thermal insulation layer 4, and inner thermal insulation layer 5 from bottom to top. The above-mentioned reinforced concrete strip 8 is 240mm thick, and the middle insulation layer 3, the outer insulation layer 4, the inner insulation layer 5, and the outer insulation layer 6 of the structural column are all 60mm thick. The thermal insulation material can be polystyrene board, extruded plastic board, polyurethane foam board, phenolic thermal insulation board, rock wool board, therma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com