Optical element axial adjusting device with aligning function

An optical element, axial adjustment technology, applied in optical elements, photolithographic process exposure devices, optics, etc., can solve problems such as radial errors, and achieve the effect of overcoming radial motion errors and improving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

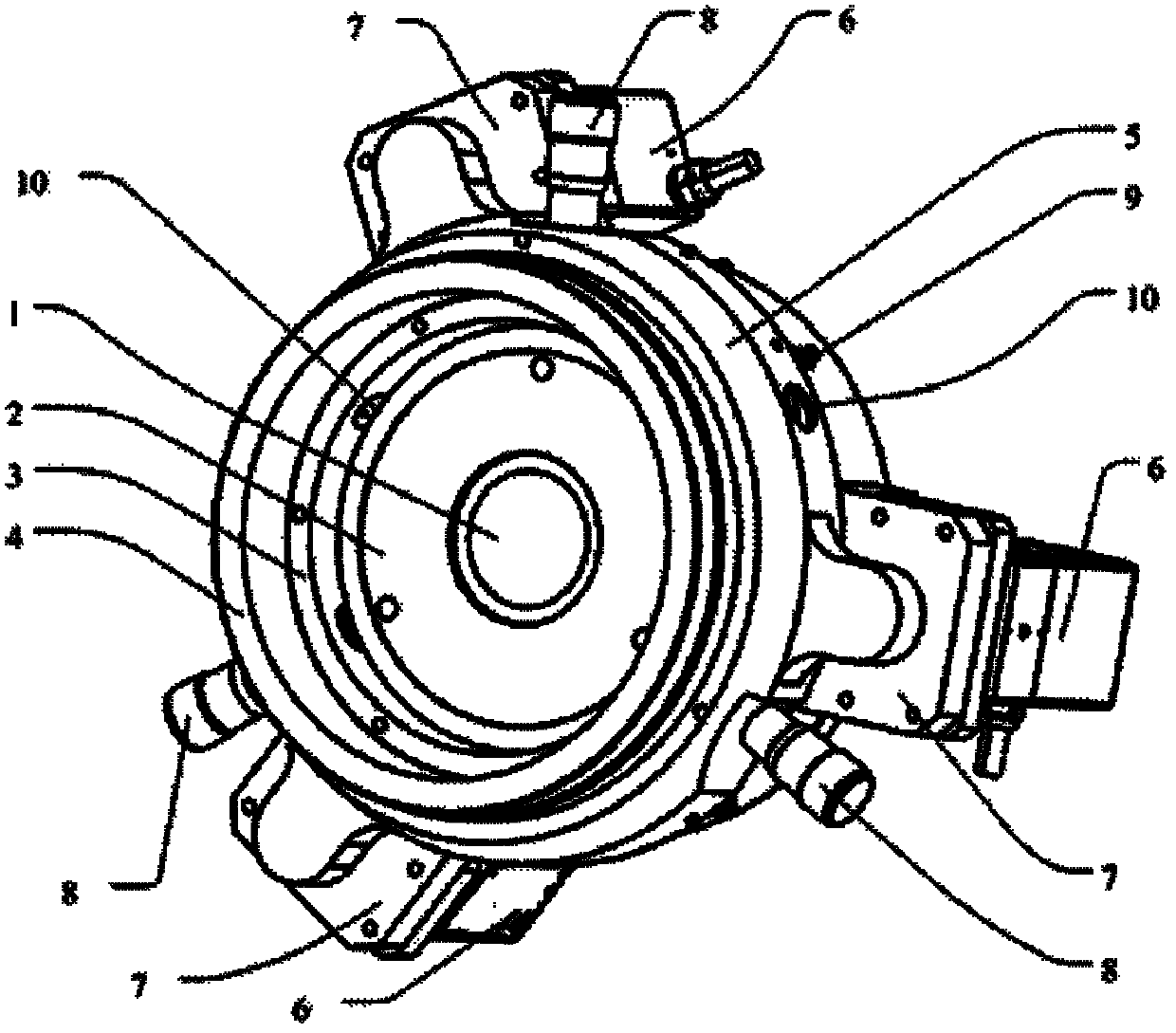

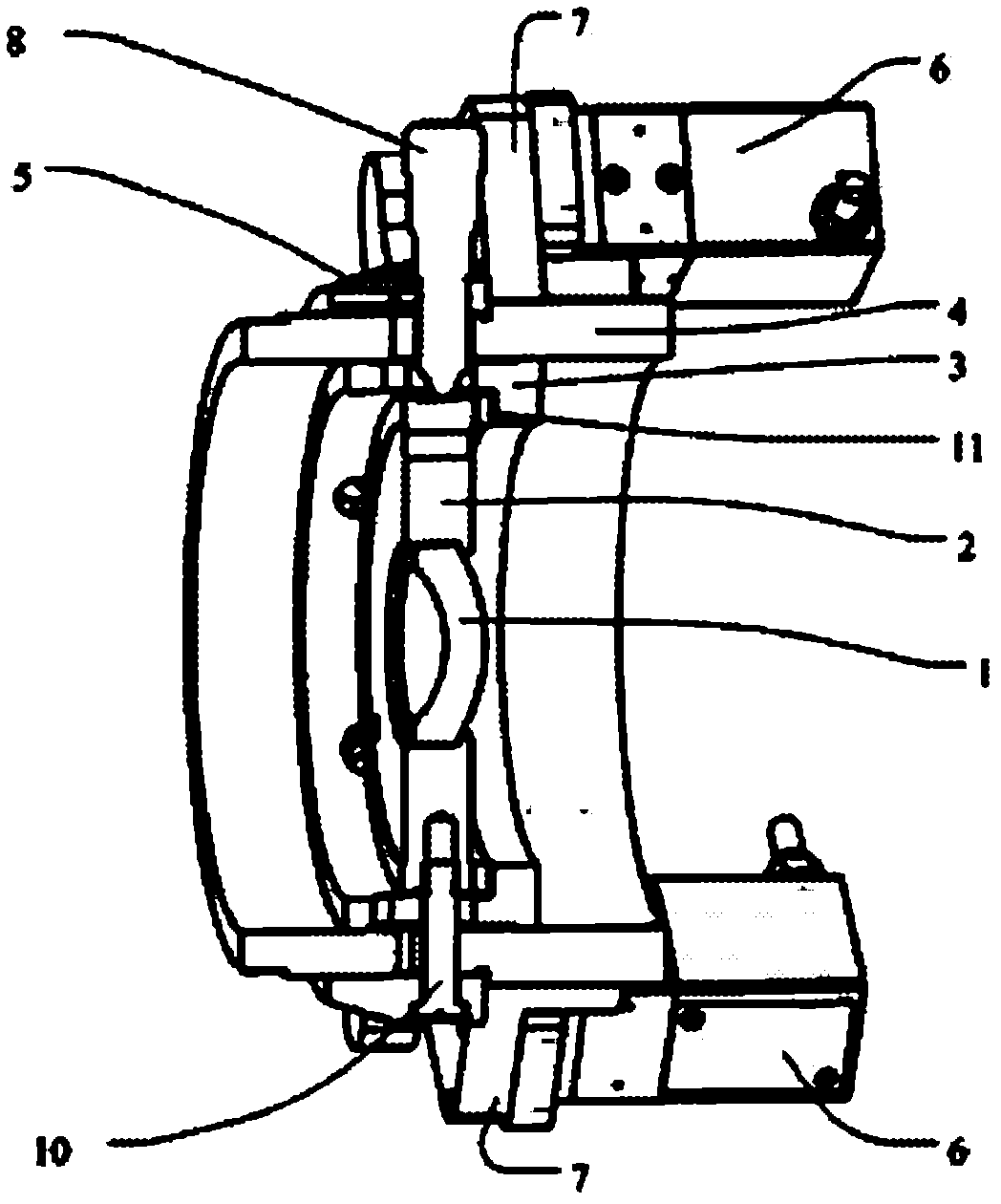

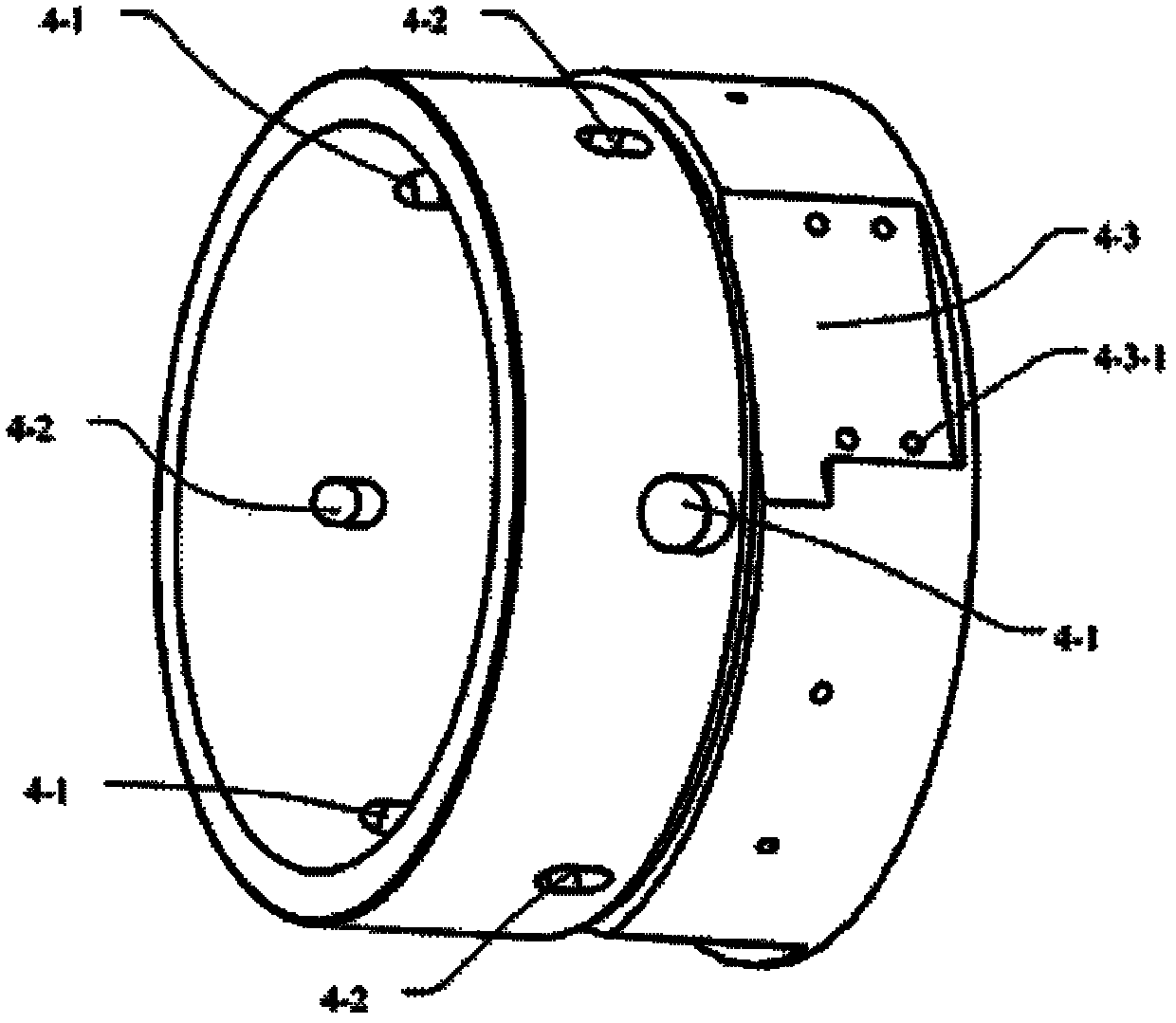

[0015] Specific implementation mode 1. Combination Figure 1 to Figure 6 Describe this embodiment, an optical element axial adjustment device with centering function, including an optical element 1, a mirror frame 2, a mirror holder 3, a lens barrel 4, a carriage 5, three piezoelectric drivers 6, three piezoelectric Driver base 7, three screw micrometers 8, three guide nails 10 and spring 9, the mirror base 3 is arranged in the lens barrel 4, the mirror frame 2 is arranged in the mirror mount 3, and the optical element 1 is arranged in the mirror frame 2 Inside; the slide frame 5 is installed on the upper stepped cylindrical surface of the lens barrel 4, and the three spiral micrometers 8 pass through the three spiral micrometer slide frame holes 5- 2. The three spiral micrometer lens barrel waist holes 4-1 set on the stepped cylindrical surface of the lens barrel 4 and the three spiral micrometer lens holder waist holes 3-2 set on the cylindrical surface of the mirror base 3 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com