Buffer aligning joint

A self-aligning and ball joint technology, which is used in drilling equipment, earth-moving drilling, drill pipes, etc., can solve the problems of inability to drill tools, lack of self-aligning function, affecting drilling construction, etc., and achieve the effect of improving construction efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

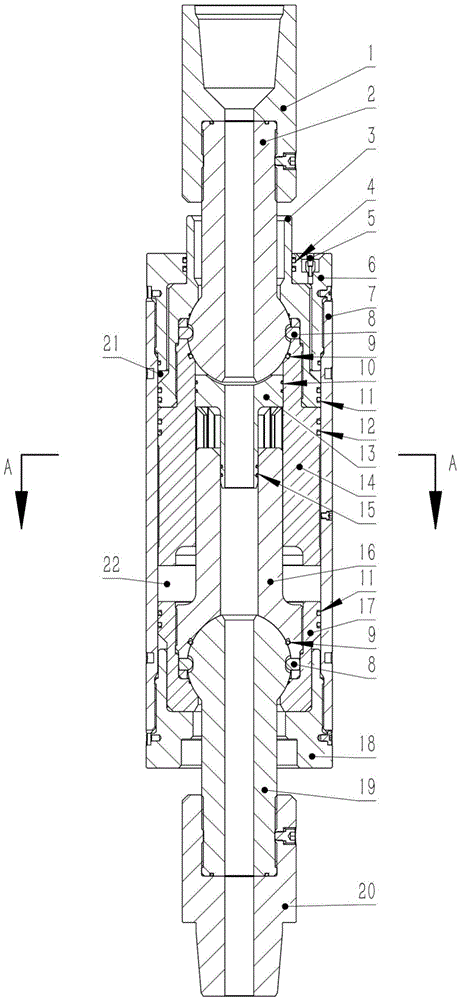

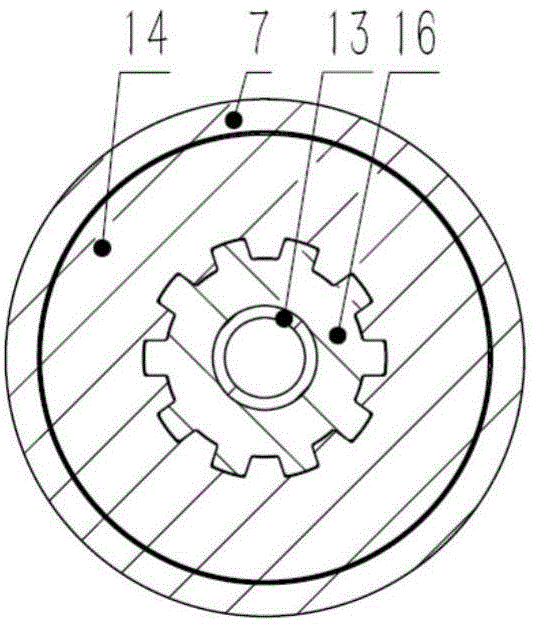

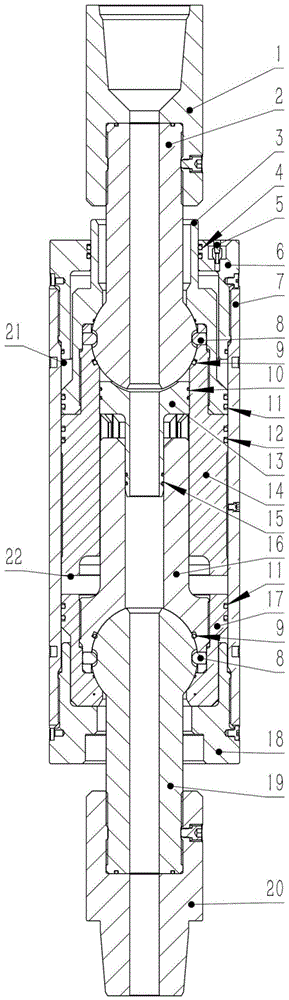

[0017] The present invention will be further described below in conjunction with the accompanying drawings.

[0018] exist figure 1 As shown in , when in use, the output end of the top driving force is connected to the upper joint 1, and the lower end of the lower joint 20 is connected to the drilling tool. The upper joint 1 is connected with the upper ball joint 2, and the upper ball joint 2 is installed in the ball hole formed after the upper ball seat 3 and the inner spline 14 are threaded, and the ball pin 8 is installed in the outer circle of the inner spline 14 through the hole. In the blind hole of the spherical outer circle of the upper ball joint 2, the upper ball joint 2 and the inner spline 14 are hingedly fixed together. exist figure 2 As shown, the inner spline 14 and the outer spline 16 are plugged together and can move relative to each other in the axial direction within a certain distance. The lower ball joint 19 is installed in the ball hole formed after t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com