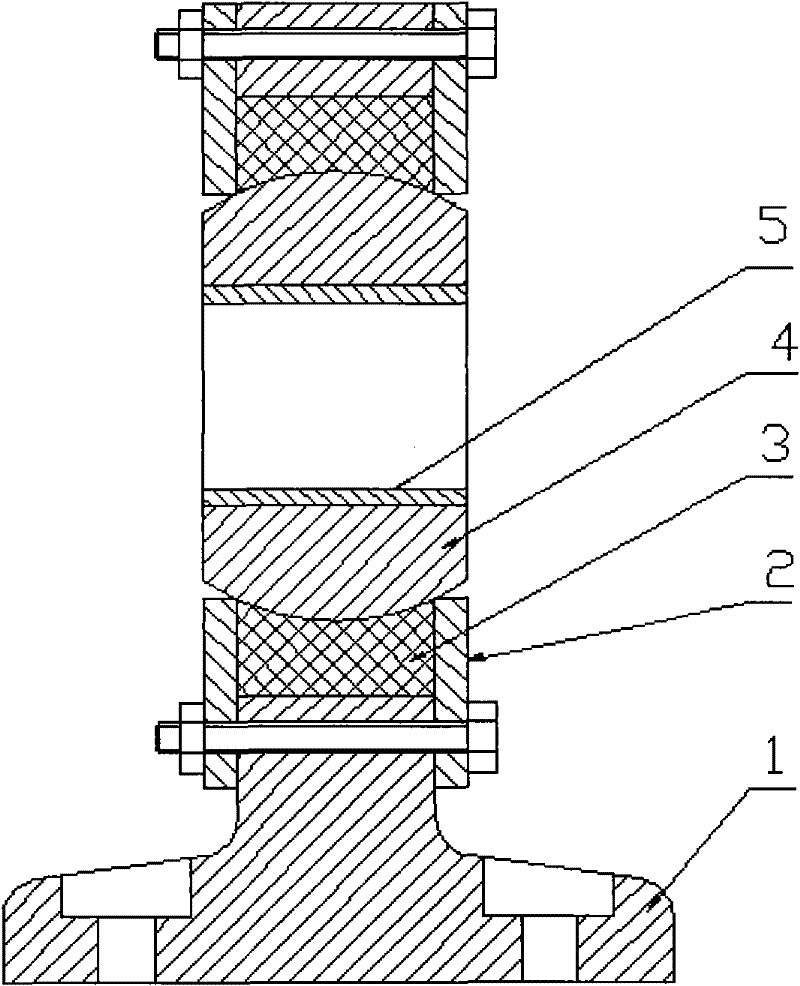

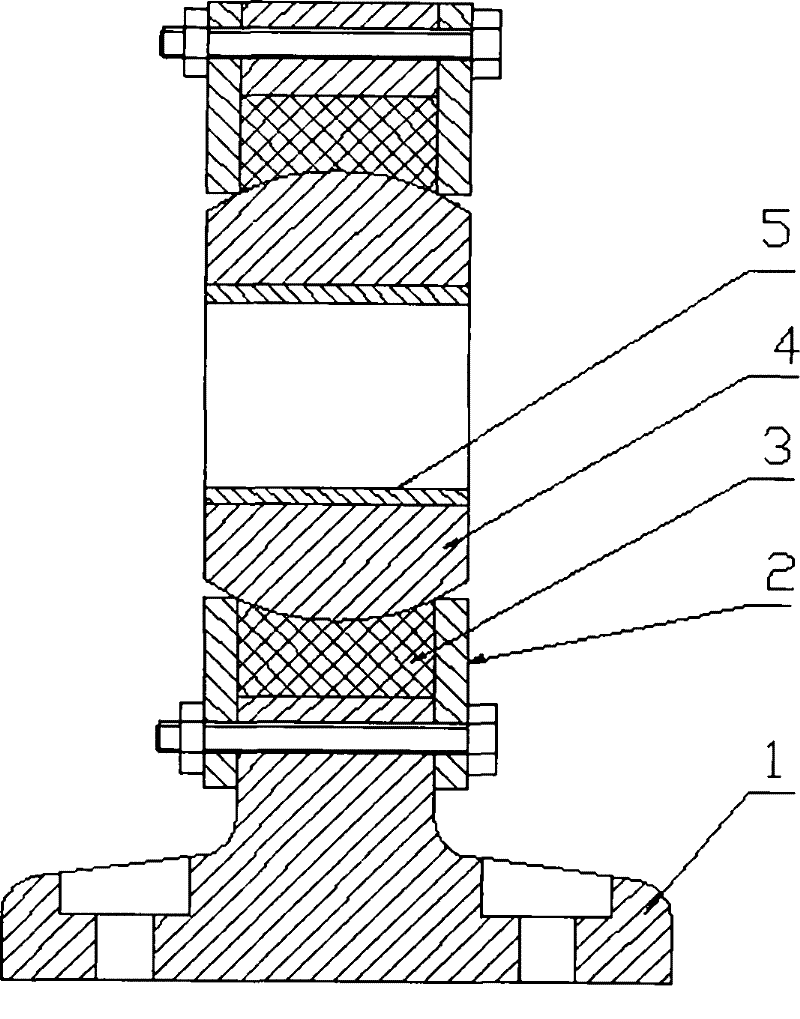

Self-adaptive shock-absorbing bearing pedestal

A bearing seat, self-adaptive technology, applied in the direction of bearing components, shafts and bearings, rigid supports of bearing components, etc., can solve the wear of the gap between the slender shaft and the bearing, the large radial error of the shaft, and shorten the service life of the mechanical design and other problems to achieve the effect of prolonging the service life and reducing the amount of wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] As shown in the figure: the bearing (5) is connected with the spherical bushing (4), and the spherical bushing (4) of the bearing (5) is connected with the rubber vibration-absorbing ring (3) to form an assembly, which is loaded into the bracket (1) In the large hole, two pieces of cover (2) are respectively fixed on the support (1) by bolts, and the cover (2) is in contact with the rubber vibration-absorbing ring (3); due to the spherical bushing (4), it has no The centering self-adaptability, under the strong surrounding of the rubber vibration-absorbing ring (3), makes the bearing seat have vibration-absorbing and self-adaptive properties at the same time.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com