Circular grating sensor angle measurement error correcting method based on error source analysis

An error correction, circular grating technology, applied in the field of measuring instruments, can solve the problems of lack of in-depth research on specific gravity, inability to guide the installation of precision shafting and adjustment of grating discs, and inability to analyze various errors in the design and assembly of rotating joints.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the accompanying drawings.

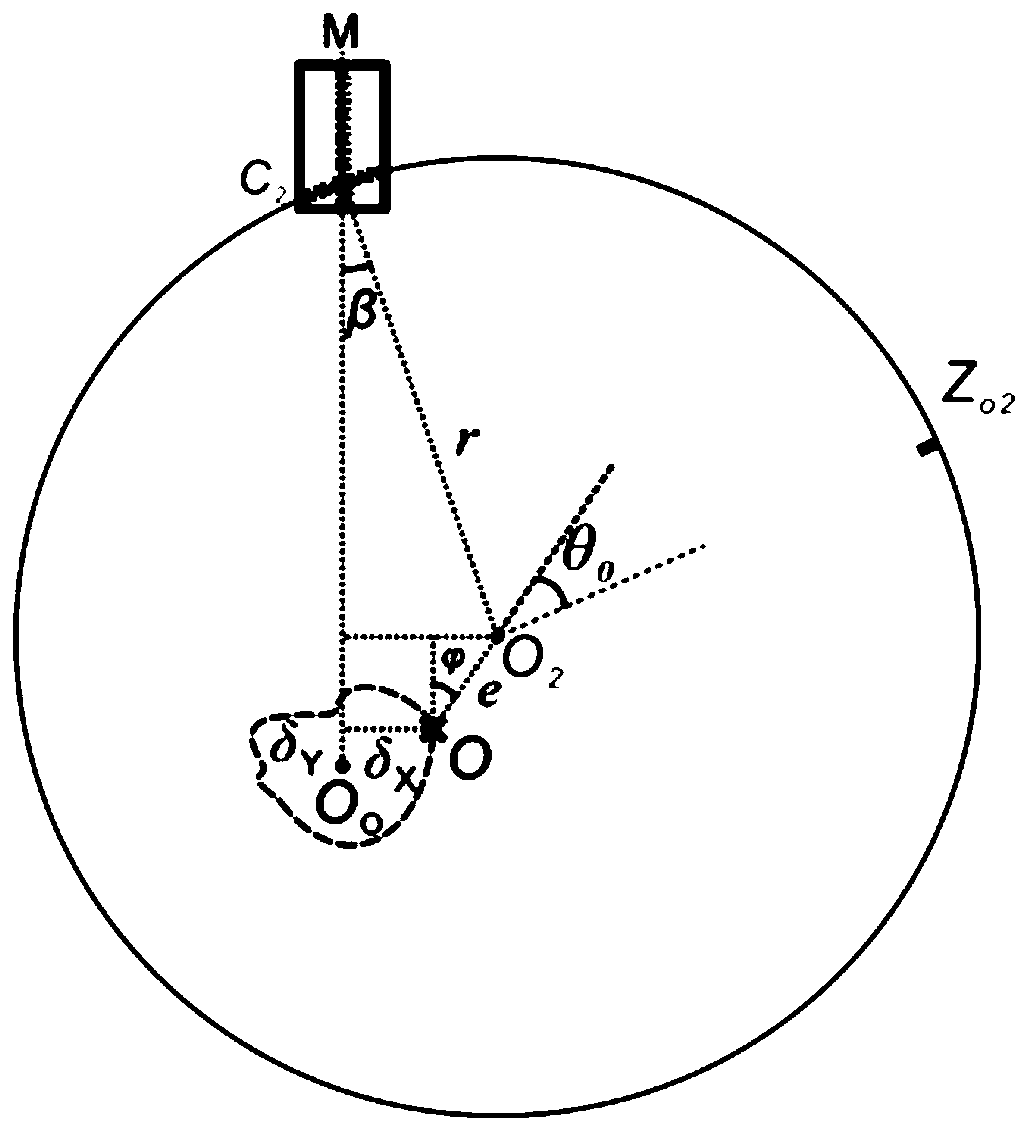

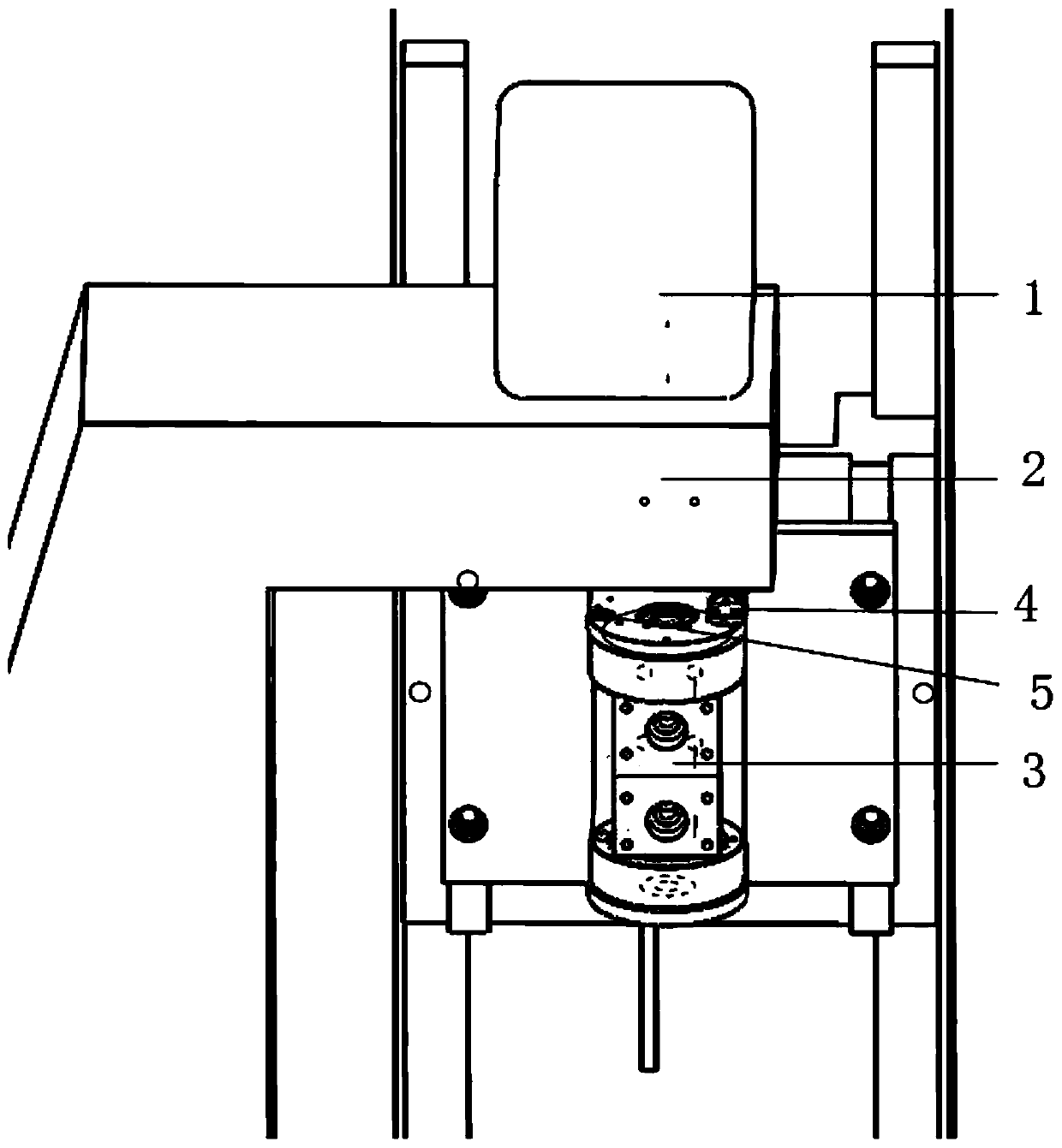

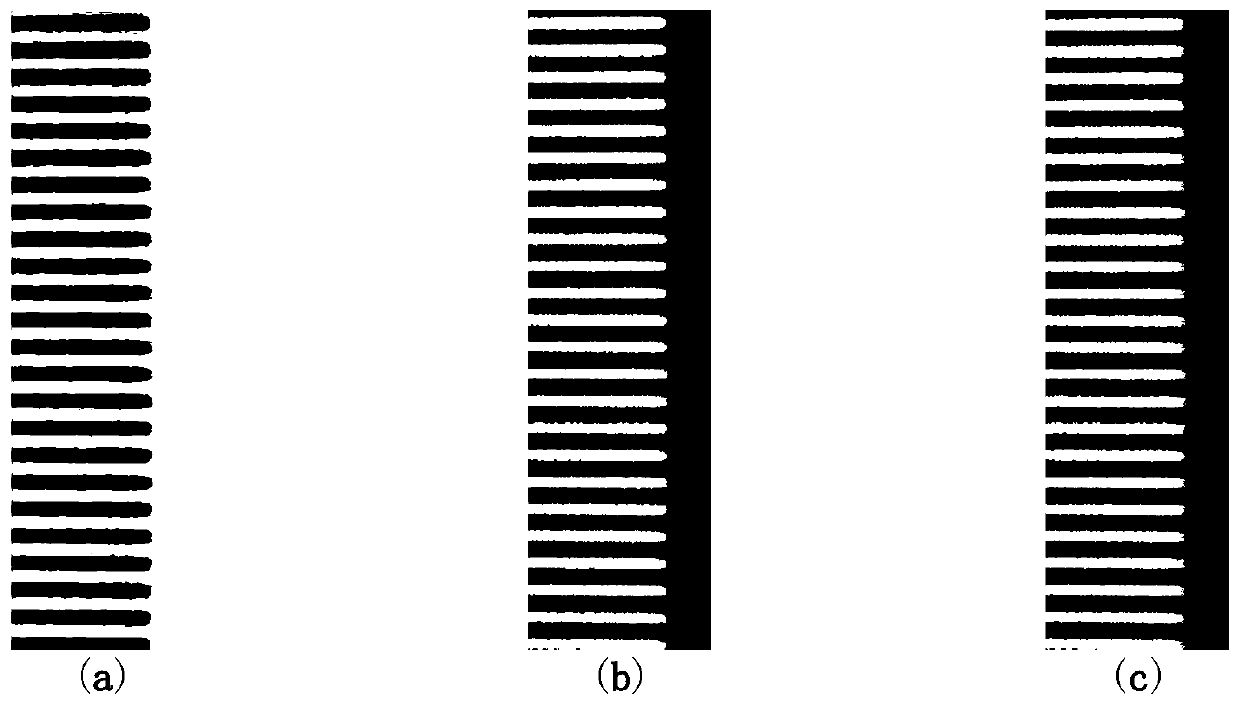

[0040] The angle measurement error correction method of the circular grating sensor based on the error source analysis of the present invention does not need to use the clamping device to install the multi-faceted prism and the autocollimator, but detects the main error items during the assembly and adjustment process of the precision shaft system , including detecting the amount of radial error movement during the installation and adjustment of the rotating shaft, and detecting the installation eccentricity of the grating disc relative to the rotating shaft during the installation of the grating disc, and bringing it into the angle measurement error model of the circular grating sensor to obtain the angle measurement error. Compared with the method of obtaining the angle measurement error by fixing the polyh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com