A method for on-line adjustment of the second-stage separation density of a three-product dense medium cyclone

A heavy medium cyclone, three-product technology, applied in chemical instruments and methods, solid separation, wet separation, etc., to achieve the effect of ensuring good operation and rapid adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

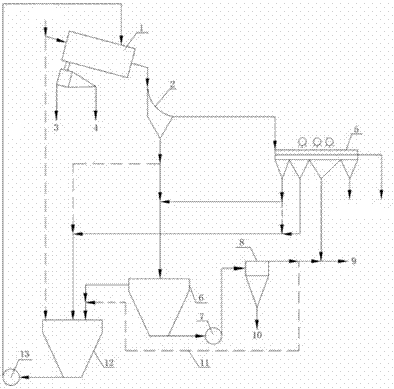

[0014] The present invention will be further described below in conjunction with the accompanying drawings.

[0015] As shown in the figure, compared with the prior art ZL201310158066.9, the improvement of the present invention is: part of the overflow of the coal slime dense medium cyclone 8 is diverted to the raw coal qualified medium barrel 12, and then it is diverted to the raw coal qualified medium In the pipeline 11 of the barrel 12, there is a link that can adjust the split flow, and the sorting density is adjusted through the split flow adjustment link, especially the sorting density of the second-stage cyclone. The sorting method is:

[0016] a. The raw coal and the qualified resuspension liquid sent by the raw coal qualified medium pump 13 are fed into the three-product heavy medium cyclone 1 for heavy medium separation.

[0017] Feeding method: Raw coal and qualified resuspension liquid are fed into the non-pressure feeding three-product heavy medium cyclone by gra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com