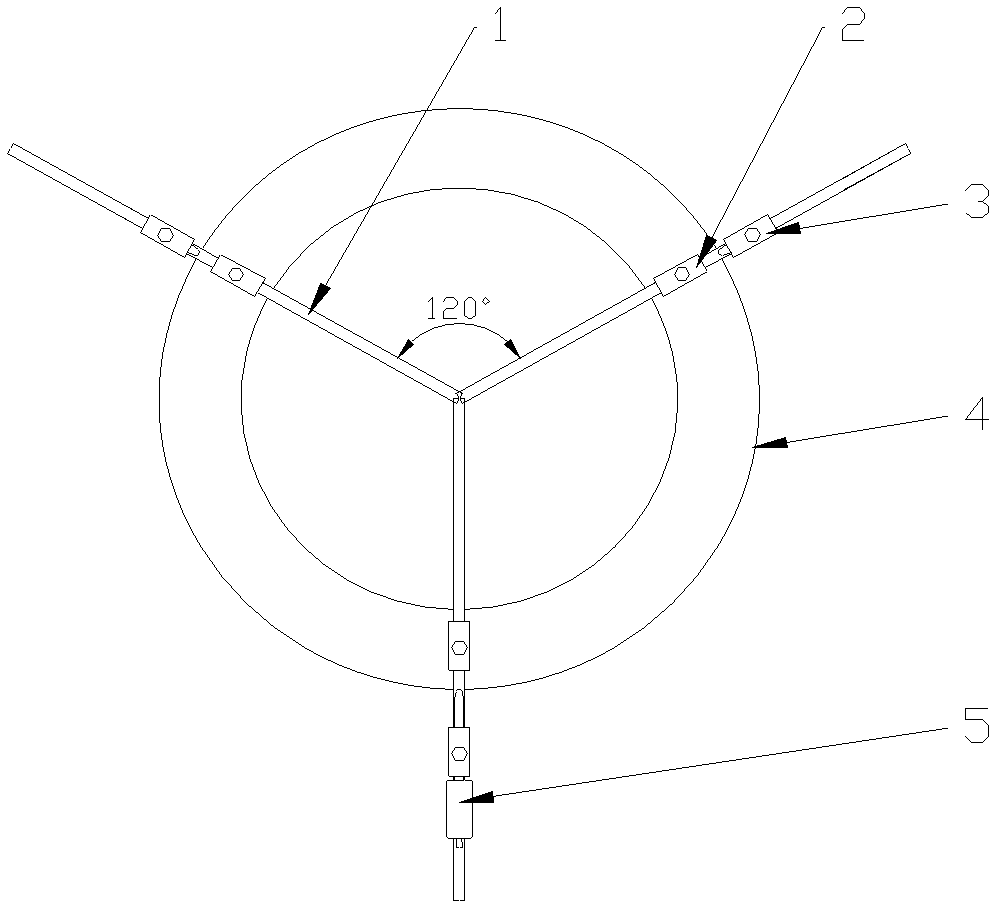

Detection apparatus for heavy and large bearings

A kind of bearing detection, large-scale technology, applied in the direction of mechanical clearance measurement, etc., can solve the problems of unstable rotation of heavy bearing parts, inaccurate measurement values, etc., to achieve the effect of reducing the intensity of manual operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

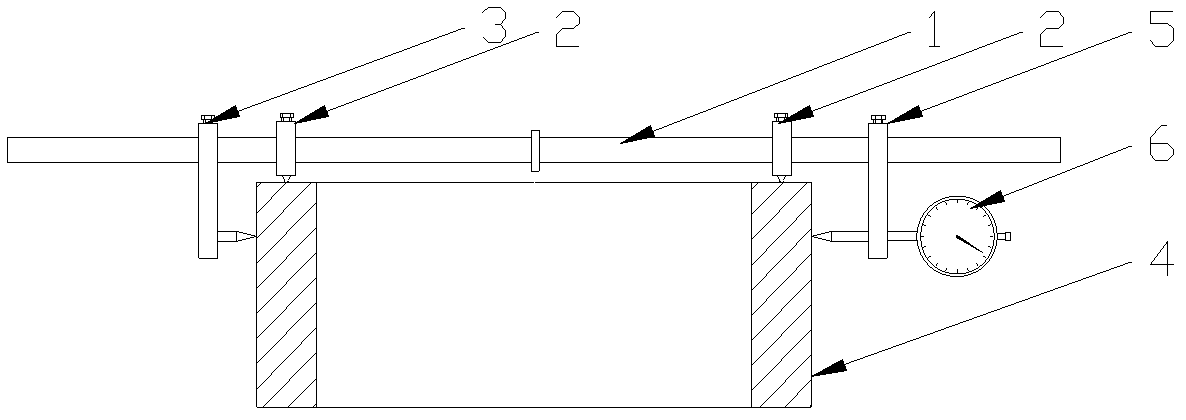

[0032] Such as figure 2 As shown, to detect the circularity error (out of roundness) of the ring piece 4: place the ring piece 4 to be tested horizontally during measurement, install an end support 2 on each of the three main body supports 1, place the three end support 2 on The fulcrum is placed in the middle of the end face of the tested ring 4, and three end supports 2 are fixed; a side support 3 is installed on each of the two main body supports 1, and the fulcrums on the two side supports 3 are connected with the tested ring. The outer diameter of 4 is in contact with the two side supports 3; a measuring support 5 is installed on the other main body support 1, and a dial indicator 6 is installed on the lower part of the measuring support 5, and the measuring head of the dial indicator 6 is connected with the measured The outer diameter of the annular part 4 contacts, and the measuring support 5 is fixed; the two side fulcrums are used as force points, and the outer diame...

Embodiment 2

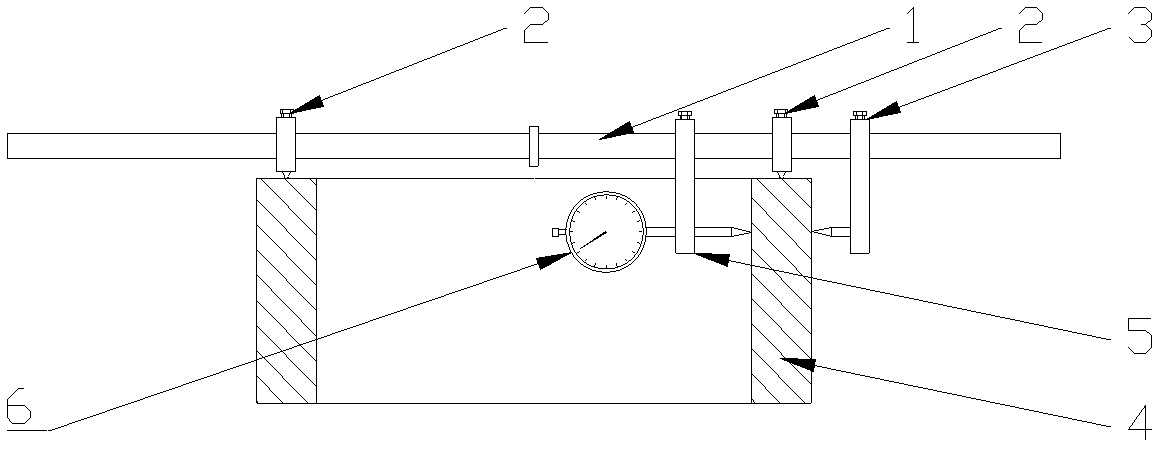

[0034] Such as image 3 As shown, to detect the thickness variation (concentricity) of the annular part 4: place the tested annular part 4 horizontally during measurement, install an end support 2 on each of the three main body supports 1, and place the three end support 2 The fulcrum is placed in the middle of the end face of the tested ring 4, and three end face supports 2 are fixed; a measuring support 5 is installed on one main body support 1, and a side support 3 is installed on the other two main body supports 1, and the two The fulcrum on the side support 3 is in contact with the outer diameter of the tested ring 4, and the two side supports 3 are fixed; a dial indicator 6 is installed on the measuring support 5, and the measuring head of the dial gauge 6 is connected to the tested ring 4 contact with the inner diameter of the measuring support 5; take the two side fulcrums as force points, rotate along the outer diameter of the tested annular piece 4, rotate the main b...

Embodiment 3

[0036] Such as Figure 4 As shown, the verticality of the outer diameter of the test ring 4 relative to the reference end face: when measuring, the ring 4 to be tested is placed horizontally, one end support 2 is installed on each of the three main body supports 1, and the three end support 2 The upper fulcrum is placed in the middle part of the end face of the tested ring part 4, and three end face supports 2 are fixed; a side support part 3 is installed on each of the two main body supports 1, and a measuring support part 5 is installed on one of the main body supports 1, and the two The fulcrum on each side support 3 is in contact with the outer diameter of the tested ring 4, and the two side supports 3 are fixed; a dial indicator 6 is installed on the measuring support 5, and the measuring head of the dial indicator 6 is connected to the tested ring. The outer diameter of 4 is contacted, and the dial indicator 6 is fixed; with the two side fulcrums as force points, the out...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com