Metering type high-precision x-ray microscope sample scanning table

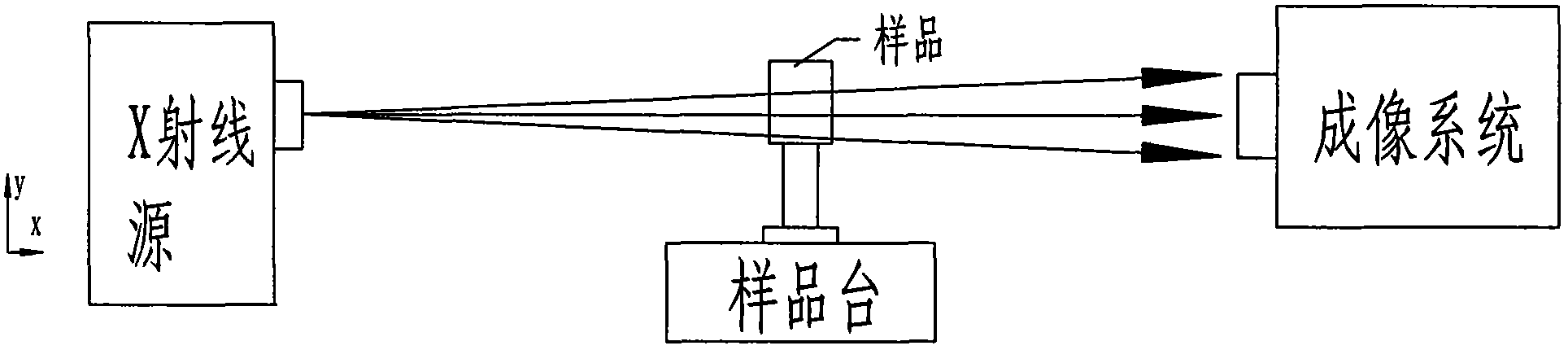

A technology of X-ray and sample stage, which is applied in the field of metrology high-precision X-ray microscope scanning sample stage, which can solve the problems of imaging error, precision error, sample position offset, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in detail below in conjunction with specific embodiments.

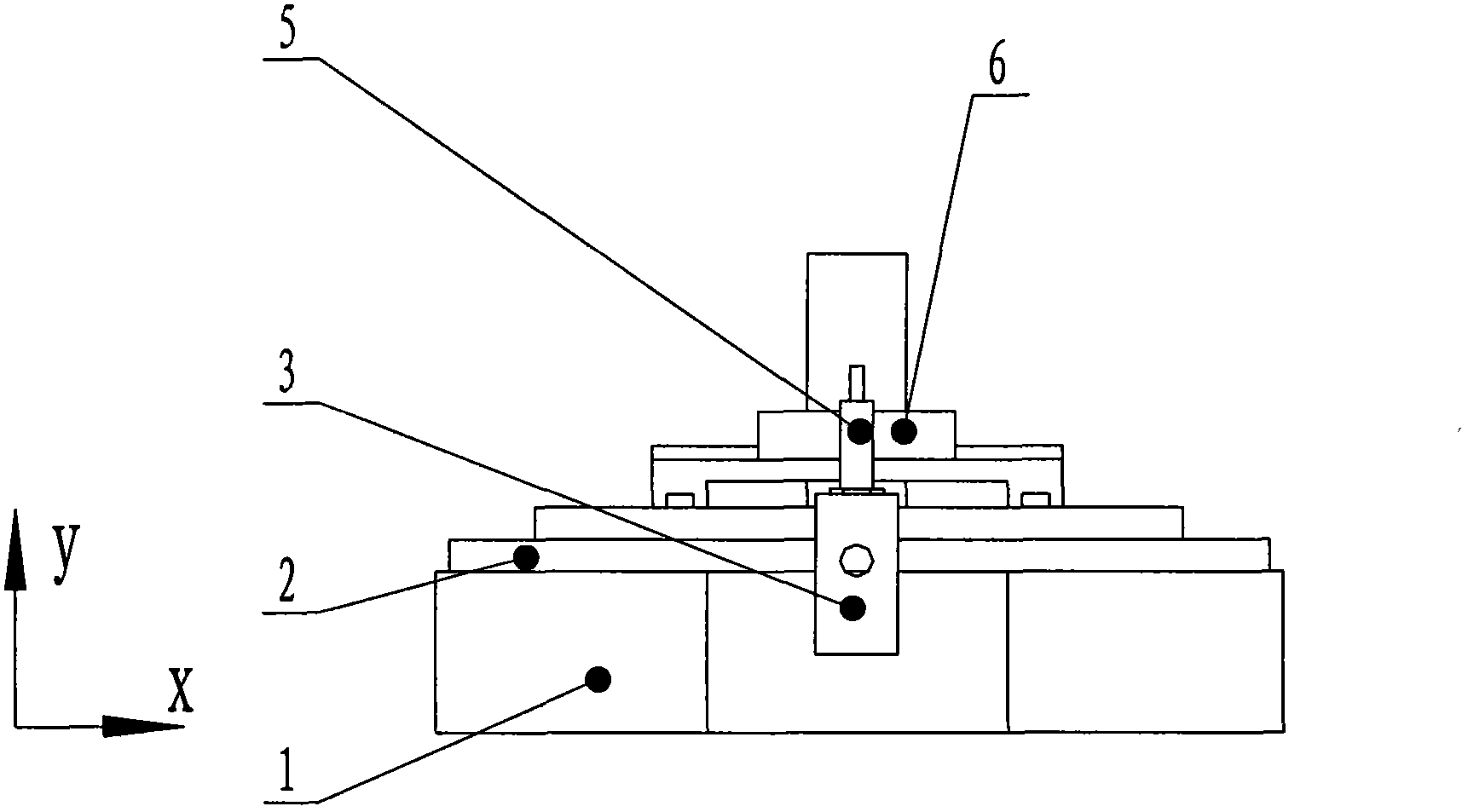

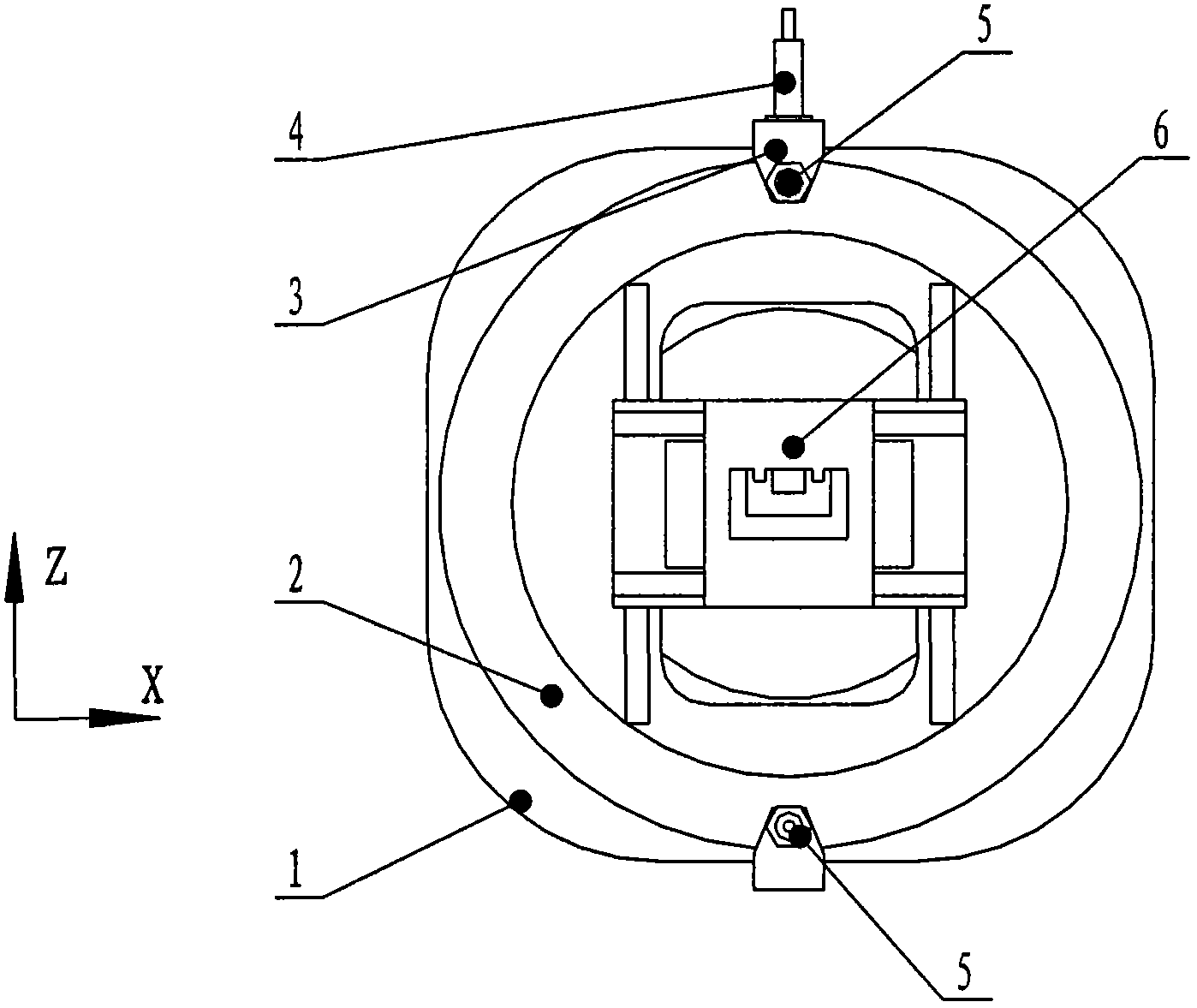

[0018] refer to Figure 2 ~ Figure 4 The scanning turntable 2 is installed on the fixed base 1, and the upper part of the scanning turntable 2 is fixedly installed with a three-dimensional positioning platform 6. The three-dimensional positioning platform includes three platforms that can move freely along the x, y, and z directions respectively. During operation, the z-direction platform can move along the guide rail fixedly installed on the scanning turntable 2, the x-direction platform can move along the guide rail fixedly installed on the z-direction platform, and the y-direction platform can move along the guide rail fixedly installed on the x-direction platform. By adjusting the positions of the three platforms, the precise positioning of the sample scanning position in three directions can be realized. The sensor mounting seat 3 is installed on the outside of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com