Measuring method based on two-cross-section radial difference and gradient extraction main shaft gyration accuracy

A technology of rotation accuracy and measurement method, which is applied in the direction of instruments, etc., can solve the problems of low measurement accuracy, measurement accuracy limitation, and inability to accurately find the rotation axis, so as to improve measurement accuracy and eliminate roundness errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] Below in conjunction with accompanying drawing, the present invention is described in further detail:

[0034] 1. The implementation process of the axial rotation accuracy measurement method:

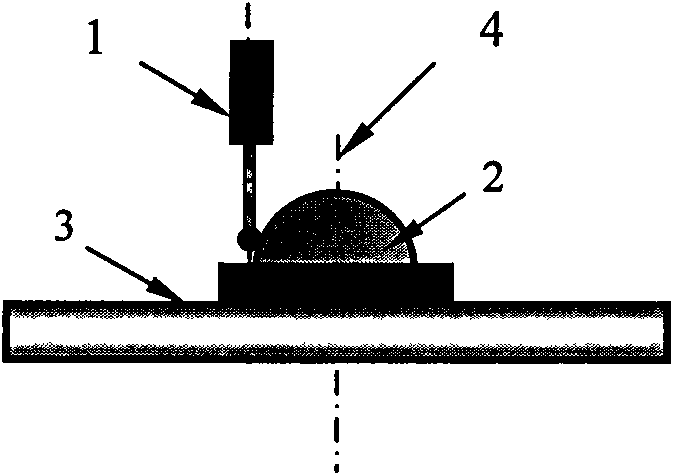

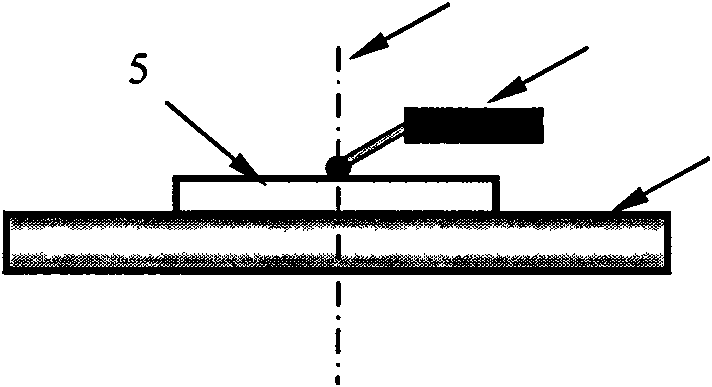

[0035] like image 3 As shown in the figure, place the flat crystal 5 on the table 3 of the turntable under test, and adjust the center of the flat crystal to coincide with the ideal rotation axis 4 of the shaft system of the turntable under test as much as possible. The center of the flat crystal is in contact; the turntable rotates at a constant speed at a speed of 6RPM to 10RPM, and the inductance sensor continuously samples on the flat crystal; the turntable rotates at a constant speed for 2 N sample data; then 2 N Each sampled data is filtered by a 2RC low-pass filter or a Gaussian low-pass filter to eliminate high-order harmonic components; then the filtered data is used to obtain the tilt amount through the least squares circle evaluation; all the filtered data are subtr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com