Large-stroke linkage mechanism two-dimensional plane roundness error calibration method

A linkage mechanism and two-dimensional plane technology, applied in the direction of measuring devices, instruments, etc., can solve the problem that the measurement range is limited by the length of the rod, and achieve the effects of low cost, efficient calibration, and convenient compensation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The technical solution of the present invention will be further elaborated below in conjunction with the accompanying drawings.

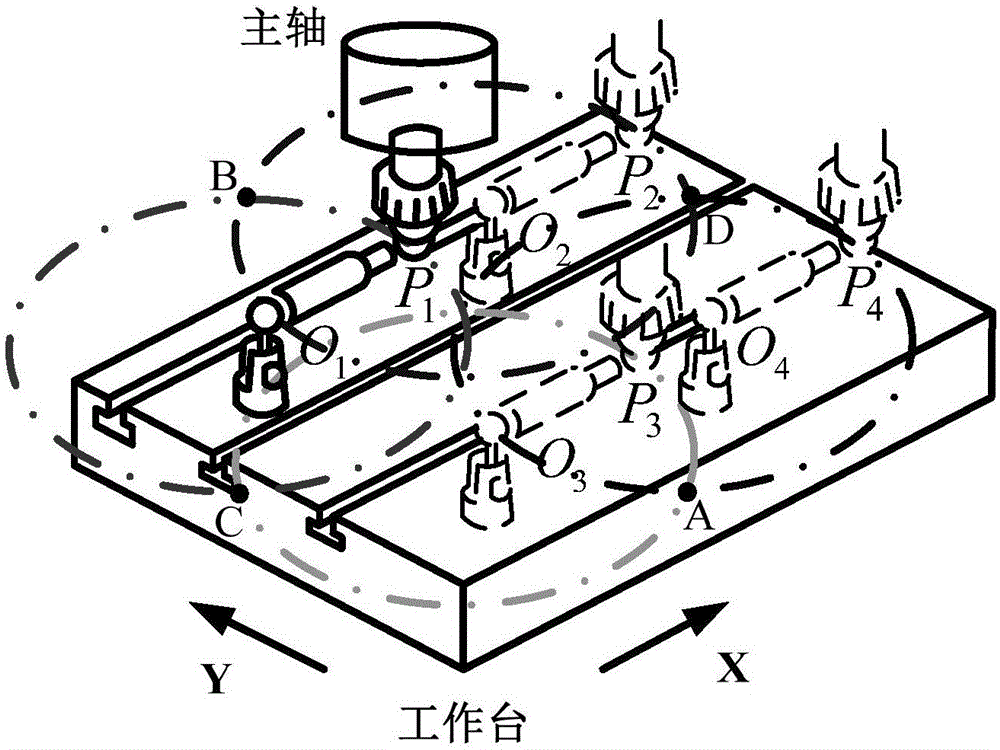

[0020] Carry out two-dimensional plane linkage error calibration for the range of 500mm×500mm of the large-travel linkage mechanism, in which the X-axis stroke is 100-600mm, and the Y-axis stroke is -600--100mm. When the ballbar is detected on the XOY plane, one end is in contact with the magnetic ball seat on the workbench, and the other end is in contact with the magnetic ball seat on the machine tool spindle.

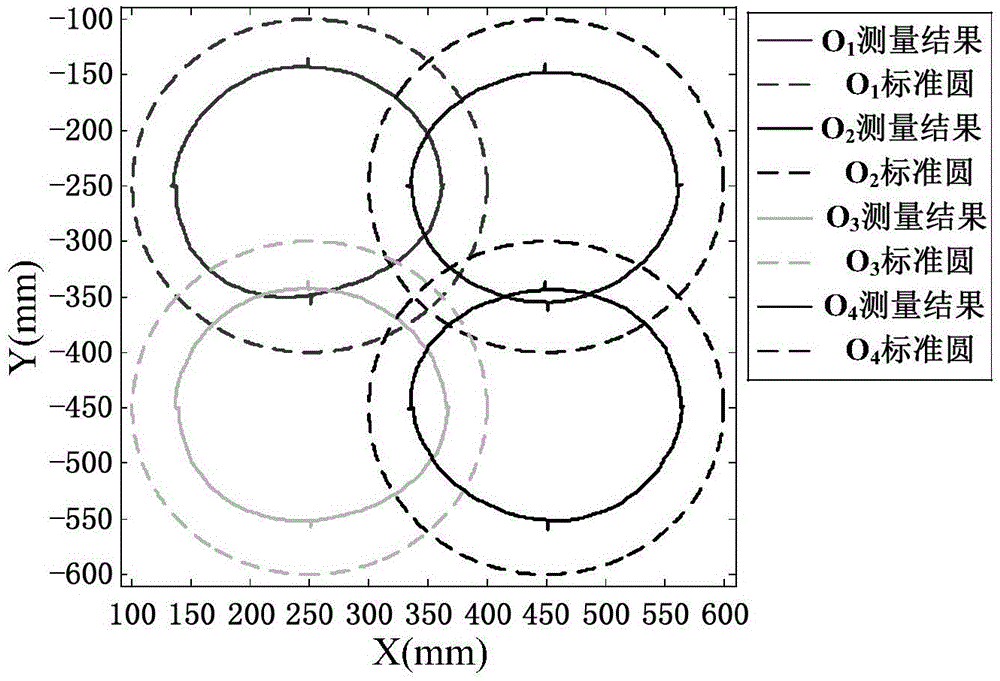

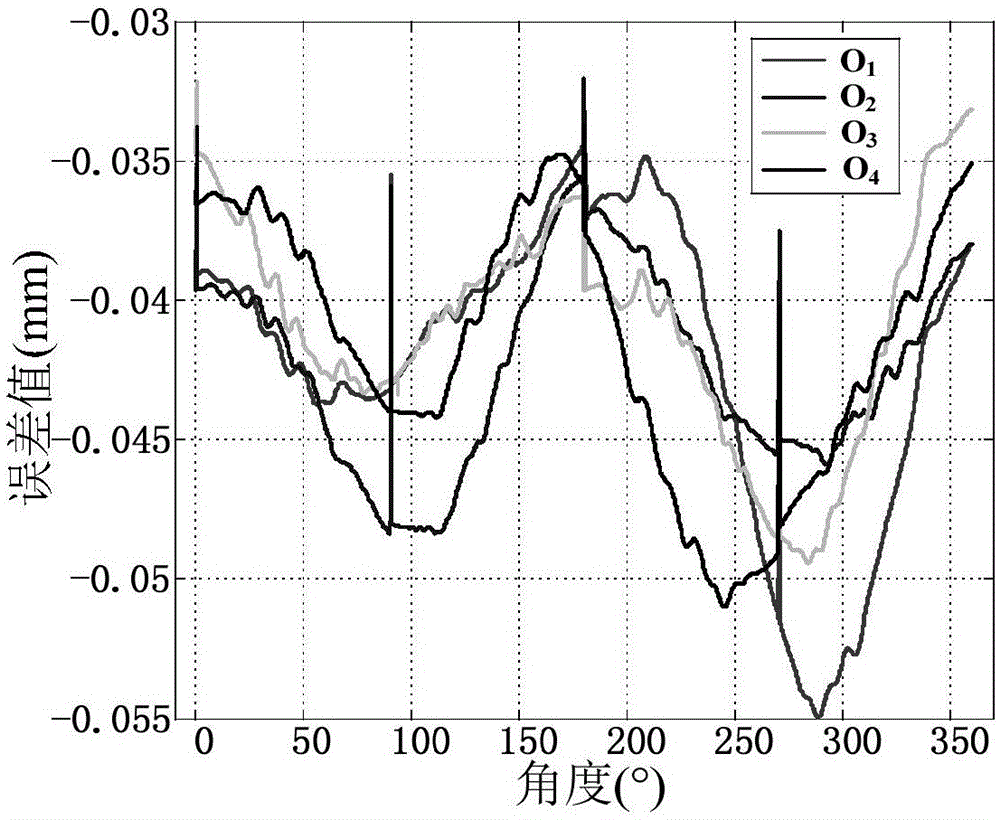

[0021] According to the overall linkage area of the mechanism is 500mm×500mm, select the rod length of the ballbar as 150mm, such as figure 1 As shown, the overall area is divided into four local areas, and the center position of each local detection area is O 1 (x 01 ,y 01 ),O 2 (x 02 ,y 02 ),O 3 (x 03 ,y 03 ),O 4 (x 04 ,y 04 ) are (250, -250), (450, -250), (250, -450), (450, -450) respectively, move the magnetic base...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com