Double-side gear rolling tester for bevel gear

A detection device, technology of bevel gears, applied in machine gear/transmission mechanism testing, angle/taper measurement, etc., can solve problems such as lack of accurate quality control and analysis equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0007] The present invention can independently be a complete bevel gear double-sided meshing detection device, and can also add a double-sided meshing detection function to a general bevel gear rolling inspection machine.

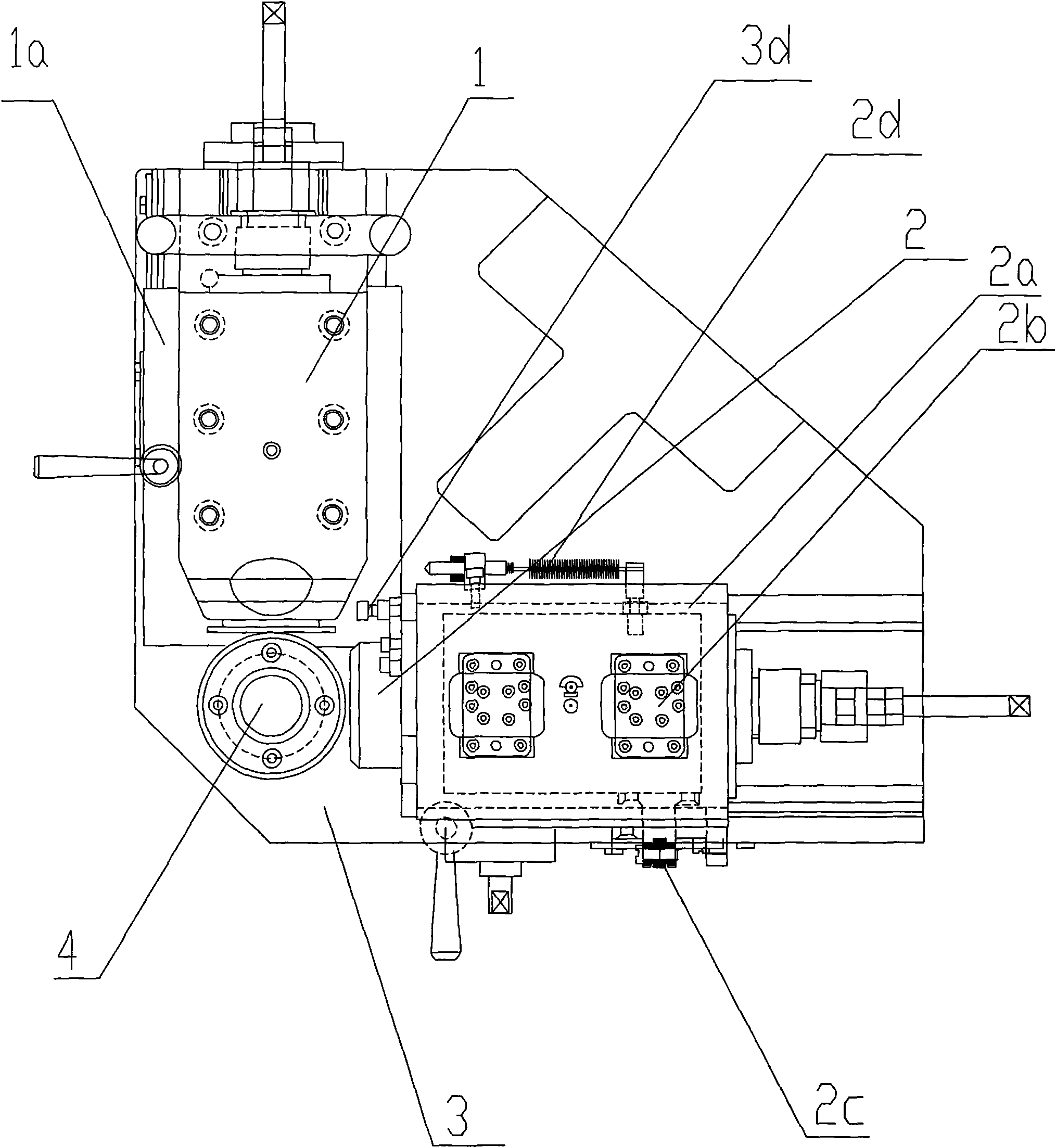

[0008] Referring to the accompanying drawings, the present invention includes a base 3, the base 3 is provided with a drive shaft 1 with adjustable relative positions, a drive shaft seat 1a, a driven shaft 2, a driven shaft seat 2a, and a connection between the driven shaft 2 and the driven shaft seat 2a. There is a linear rolling guide rail 2b between them, and the driven shaft 2 can be rotated on the driven shaft seat 2a, and can also move in a limited manner along the linear rolling guide rail 2b.

[0009] The radial error detection of bevel gear must carry out rolling detection under the meshing state of the tested gear without backlash. For this reason, the present invention also provides an orientation adjustment device 2d of the driven shaft 2. In th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com