Plate defect detection device and detection method thereof

A defect detection and measurement device technology, applied in measurement devices, optical testing flaws/defects, analysis of materials, etc., can solve the problems of being easily affected by personal factors, large detection errors, inconsistent detection standards, etc., to achieve good market prospects, Simple structure and convenient measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be described in further detail below with reference to the accompanying drawings and preferred embodiments. However, it should be noted that many of the details listed in the specification are only for readers to have a thorough understanding of one or more aspects of the present invention, and these aspects of the present invention can be implemented even without these specific details.

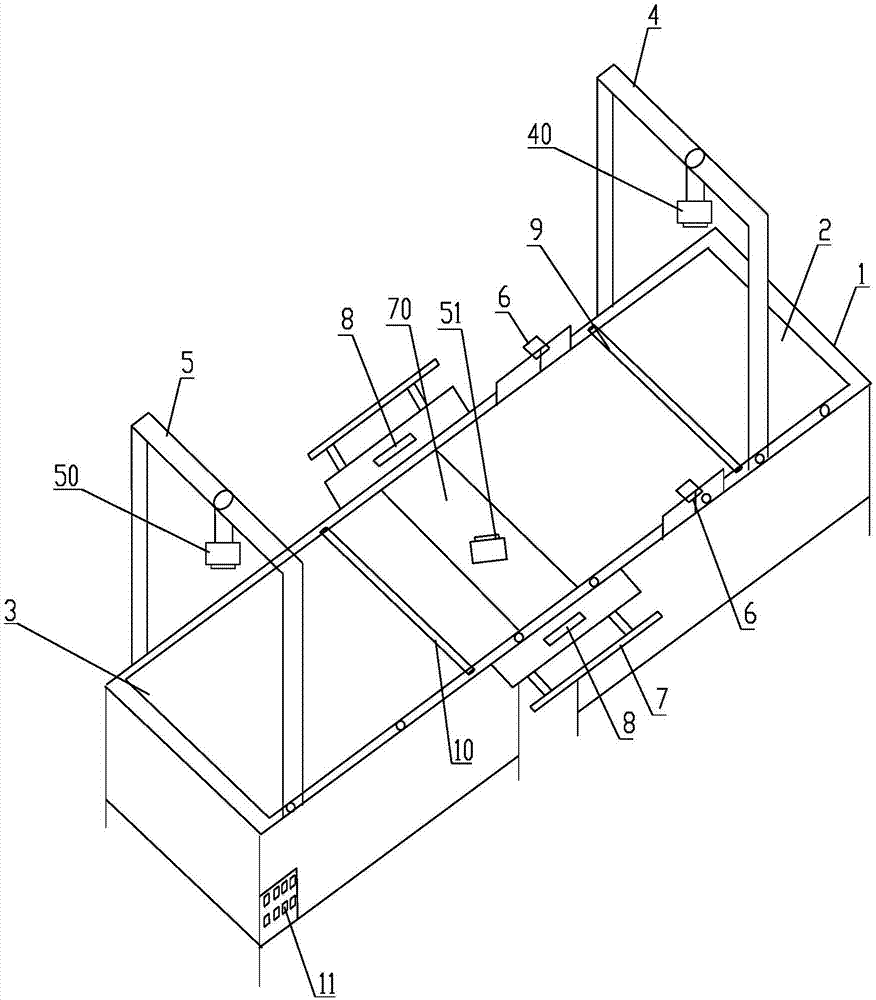

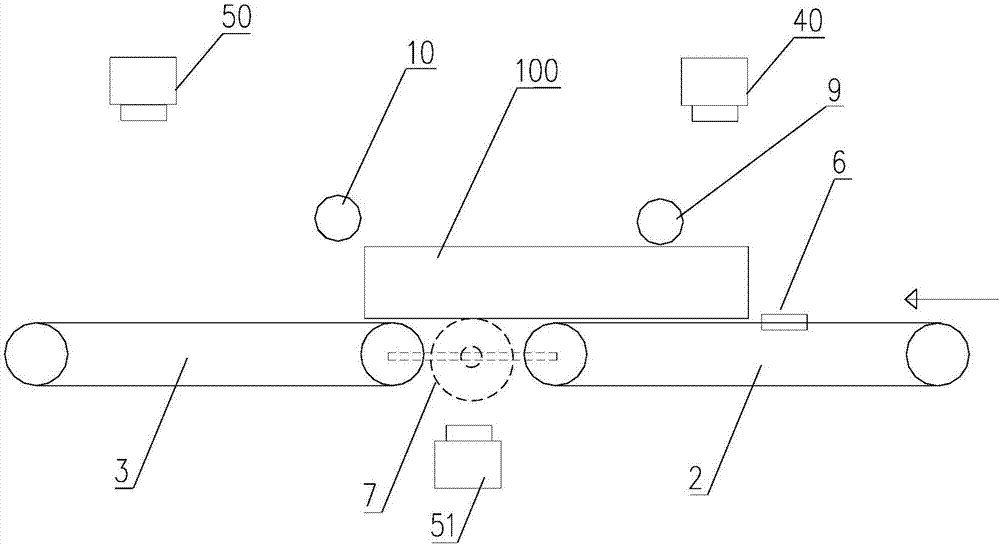

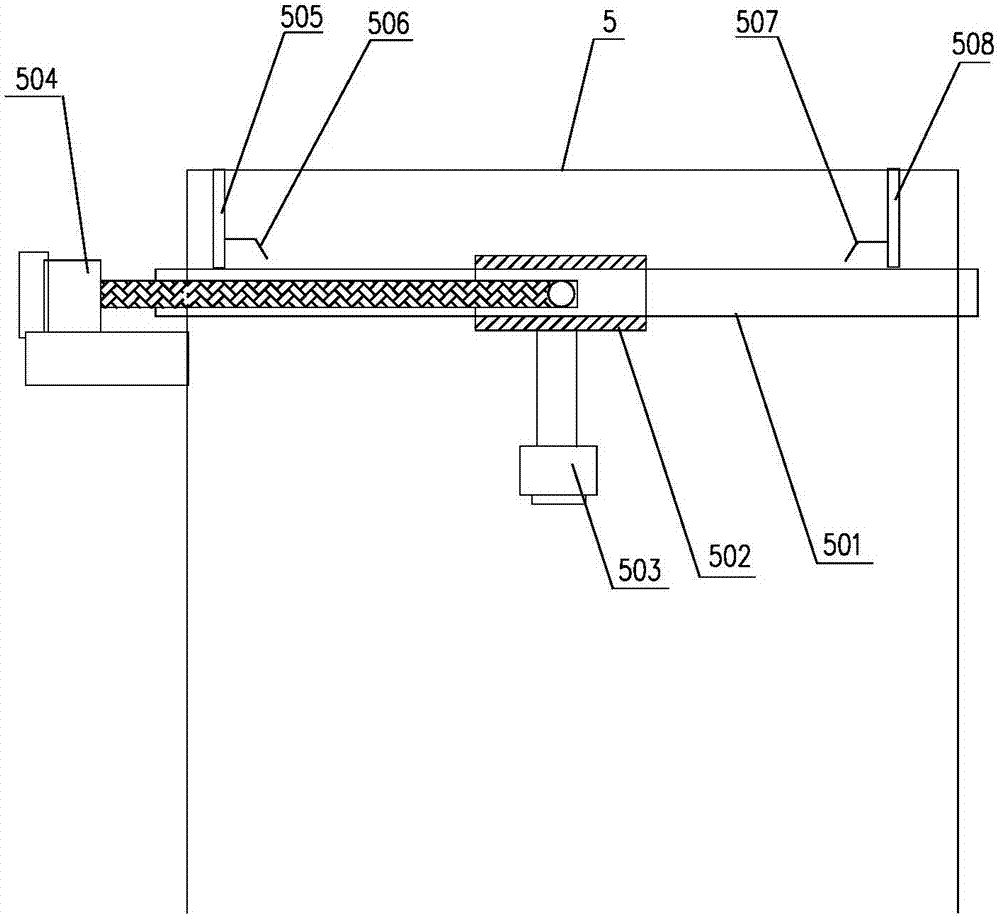

[0027] Such as figure 1 and figure 2 As shown, according to a defect detection device for a plate according to the present invention, the defect detection device includes a frame 1, and a first conveying mechanism 2, a second conveying mechanism 3 and a transverse exaggerated plate are laid horizontally on the upper surface of the frame 1. The first supporting beam 4 connected above the first conveying mechanism 2 and the second supporting beam 5 laterally conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com