Patents

Literature

45results about How to "Precise unloading" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

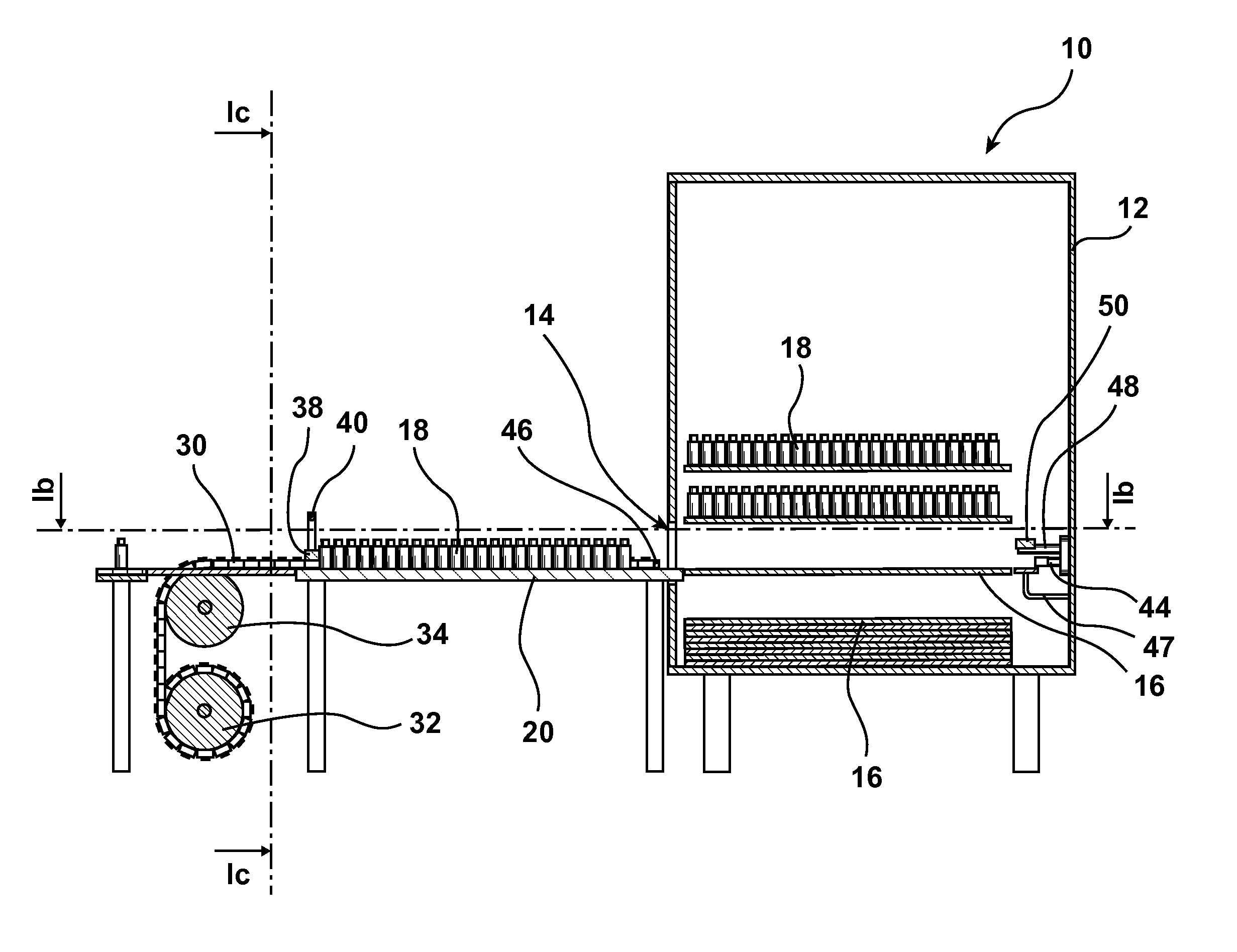

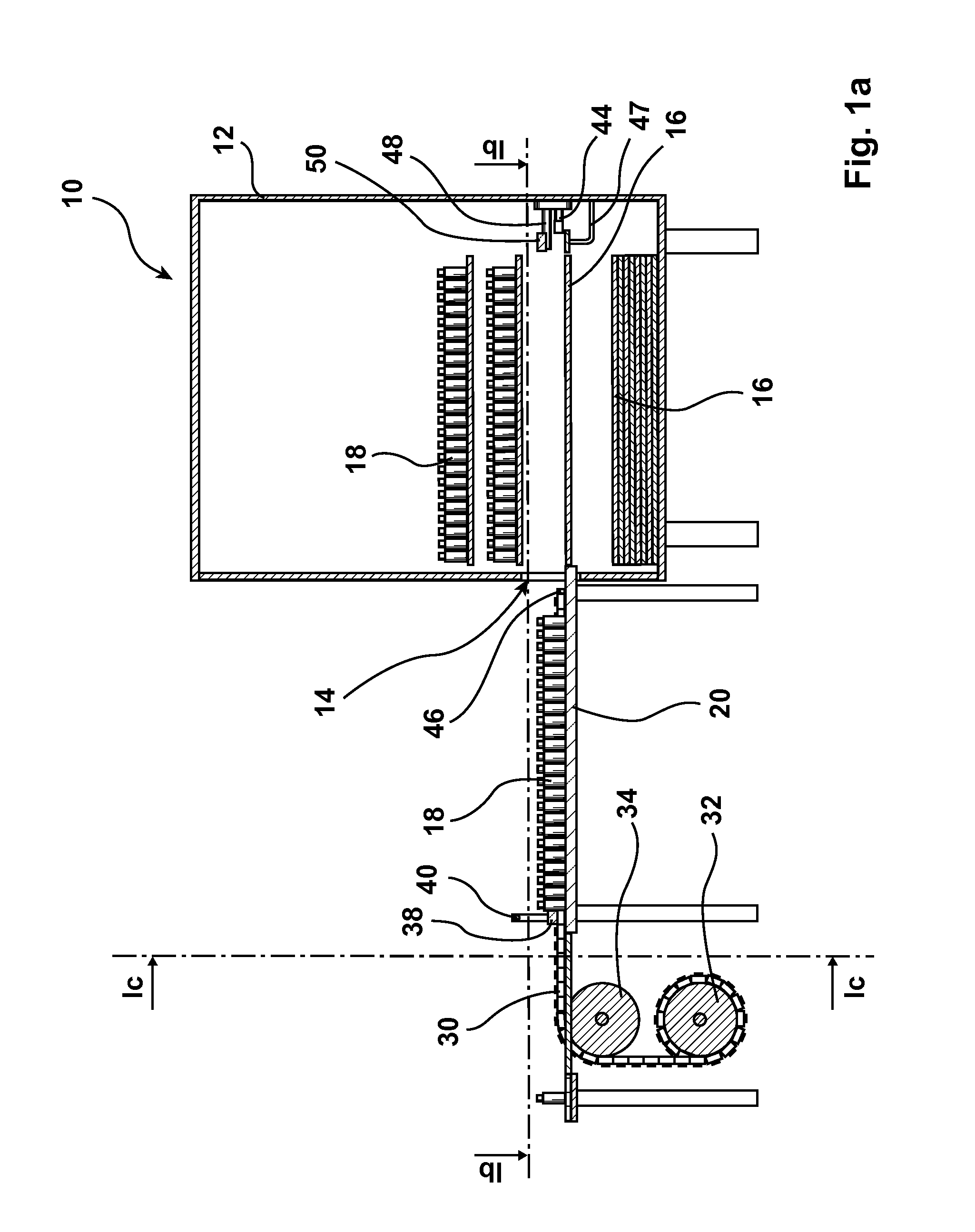

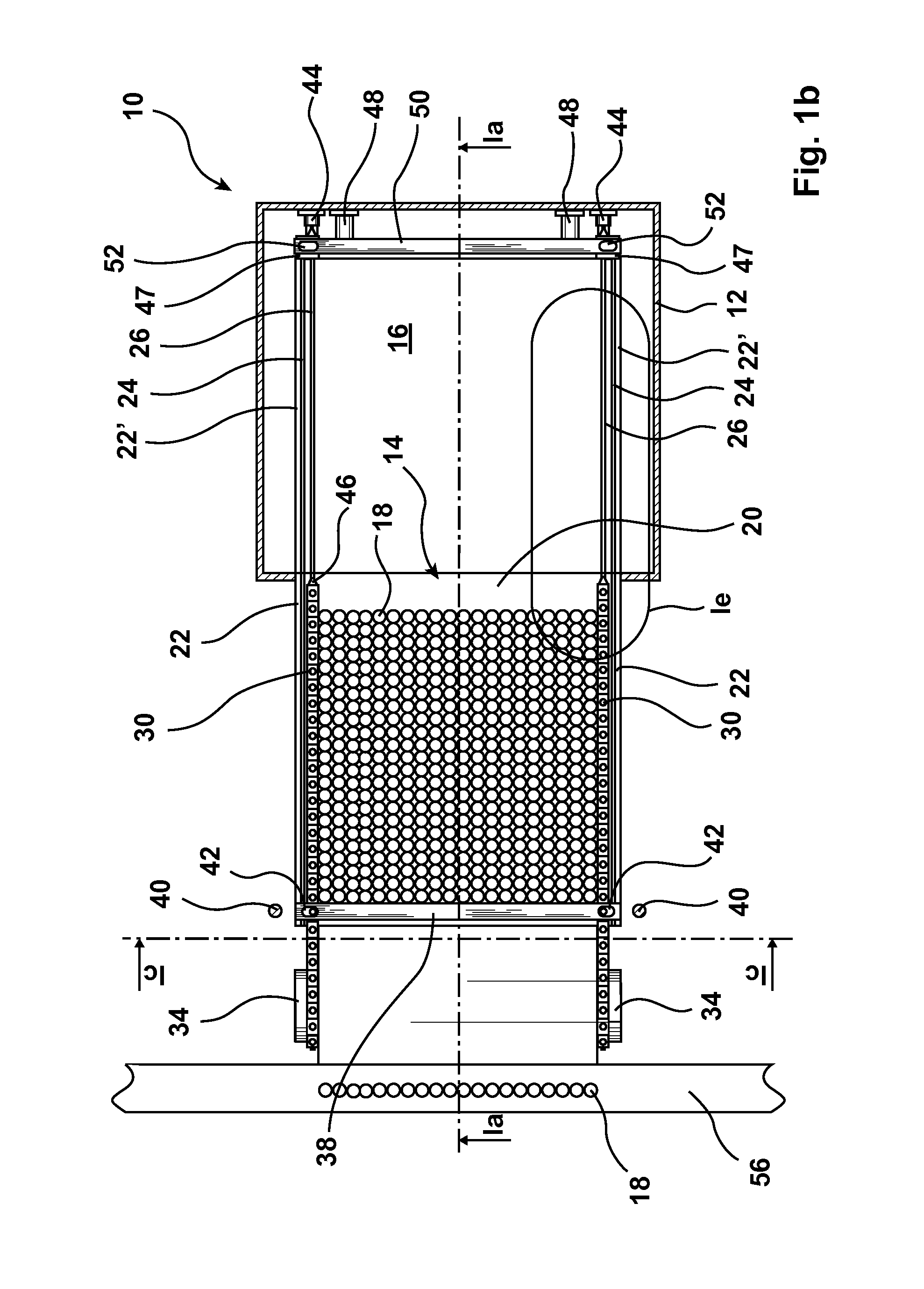

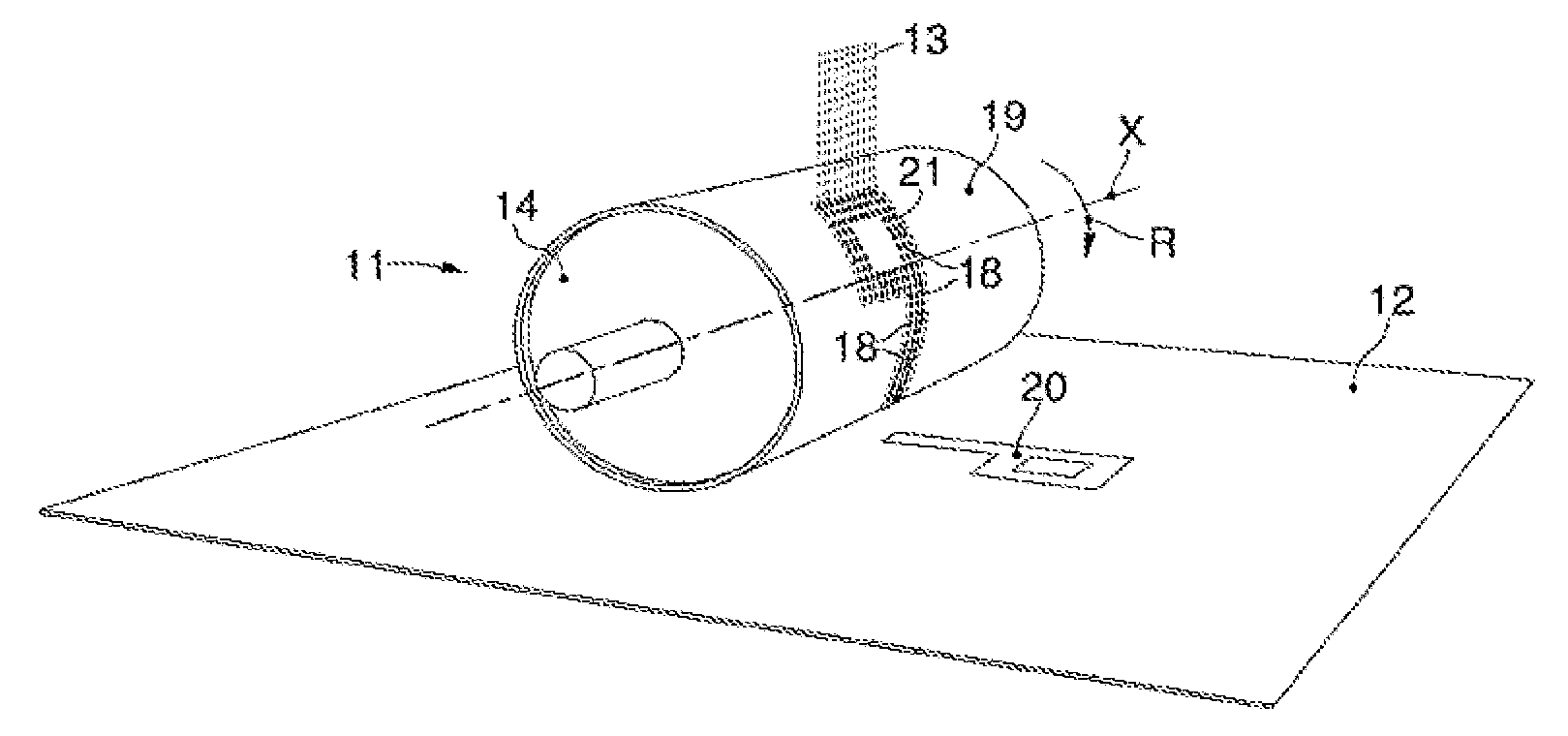

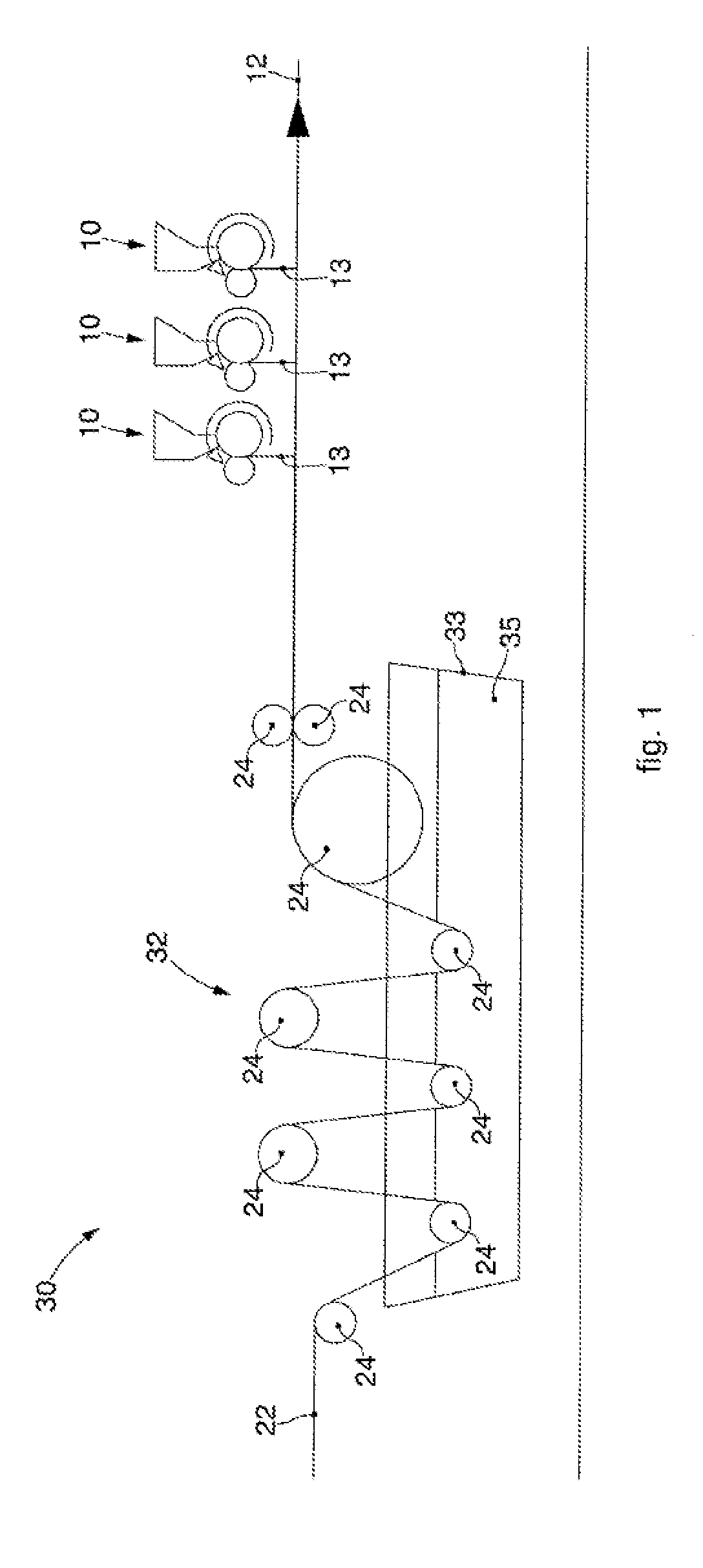

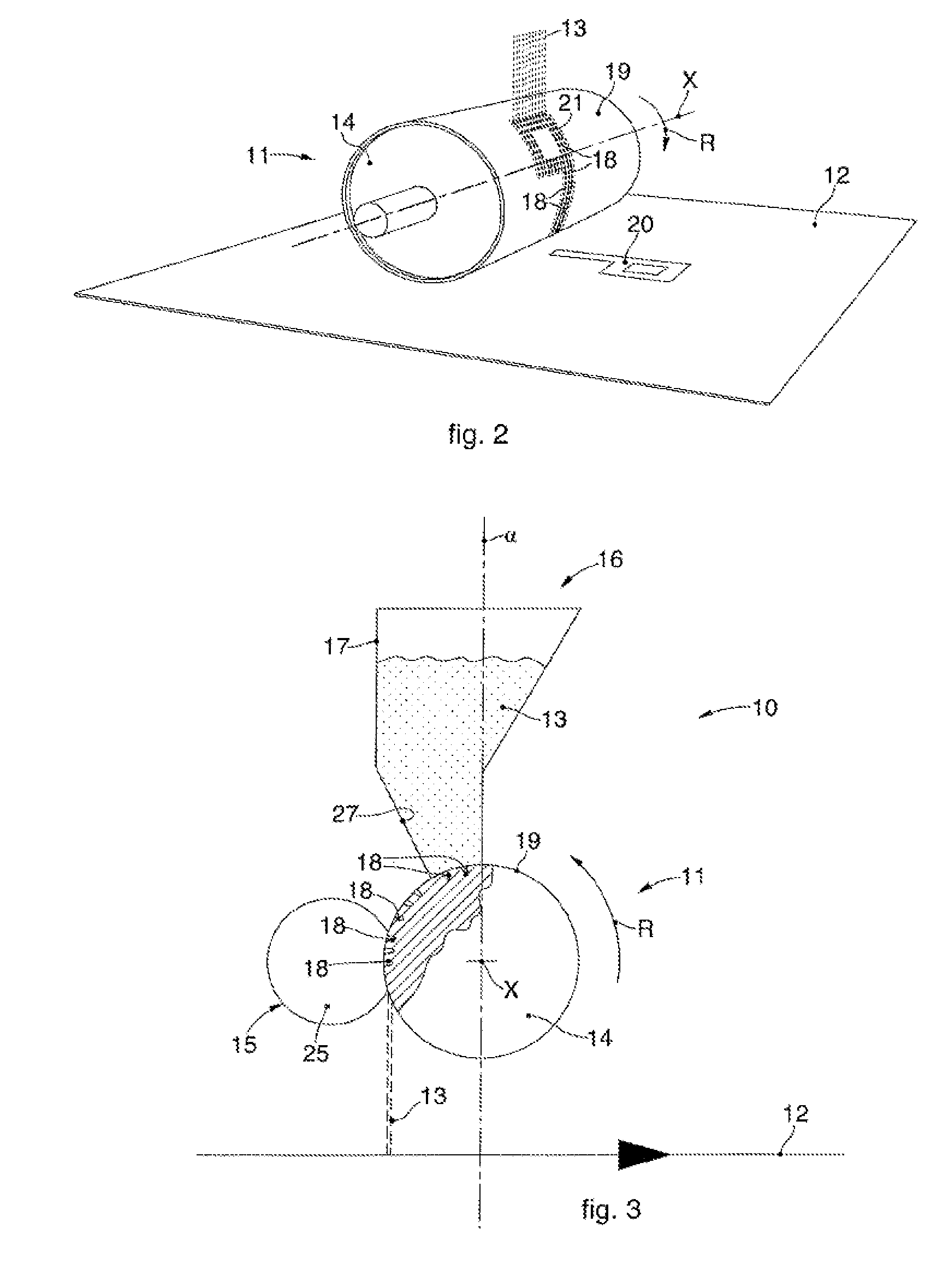

Apparatus for loading and unloading a tray of a freeze drying plant and method thereof

InactiveUS20090019724A1Increase capacityDistanceDrying solid materials without heatDrying machines with progressive movementsFreeze-dryingMechanical engineering

The object of the disclosure is an apparatus for loading and unloading a tray (16) of a freeze drying plant (10) with a number of vials (16), with a transfer table (20) provided upstream of the freeze drying plant (10) for receiving temporarily said vials (18), and with a pusher apparatus for displacing said vials (18) from said transfer table (20) to said tray (16) or from said tray (16) to said transfer table (20), said pusher apparatus including a right-handed and a left-handed transport carriage.(30). To provide an apparatus for loading and unloading a tray of a freeze drying plant that allows for proper unloading of the tray even if the distance between neighbouring trays of the freeze drying plant is reduced to a minimum is achieved in that the pusher apparatus further includes a loading element (38) and an unloading pusher (50), said loading element (38) being disposed outside of the freeze drying plant (10) whilst the unloading pusher (50) is arranged inside the freeze drying plant (10).

Owner:ACCURRO GMBH

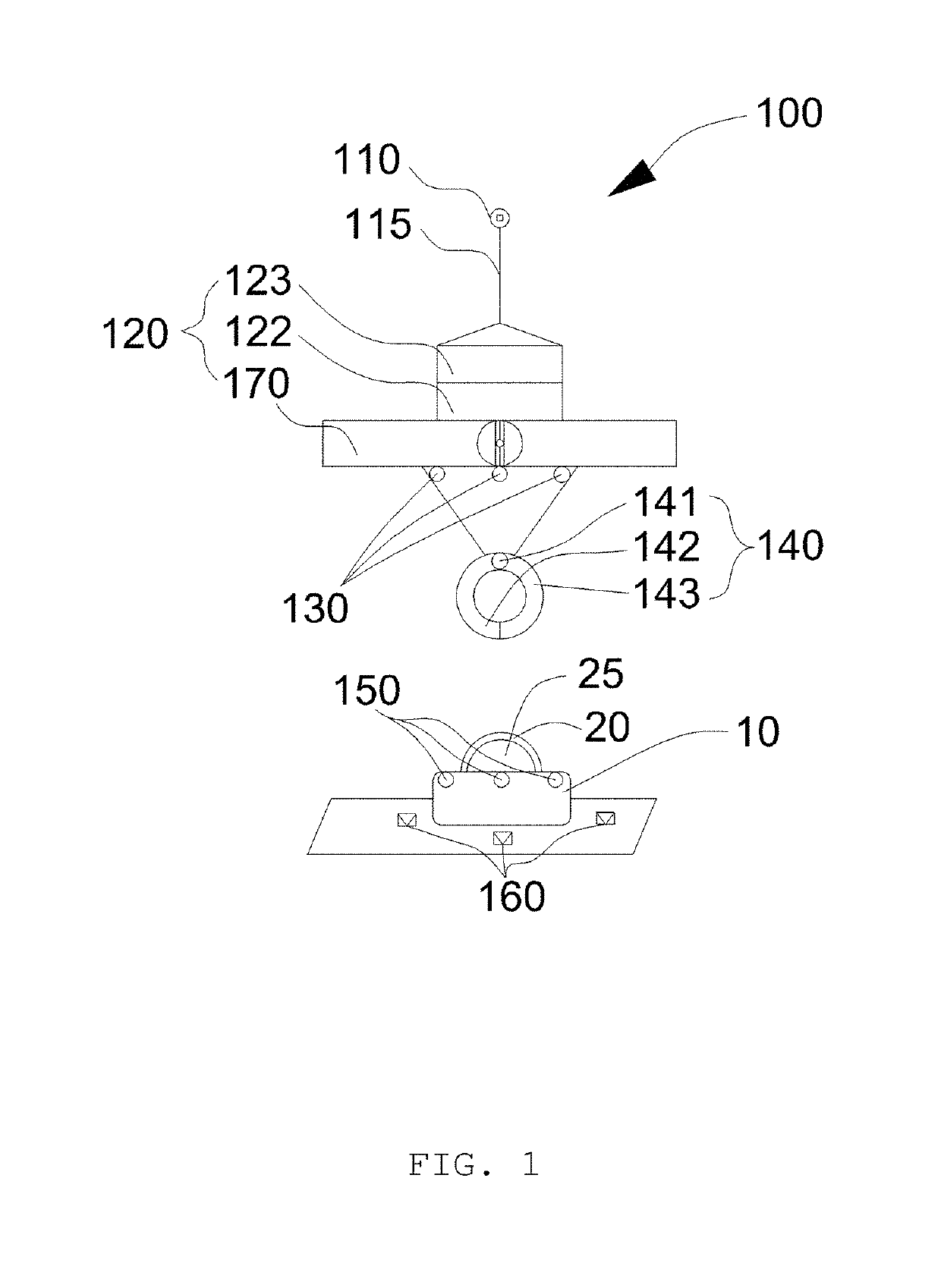

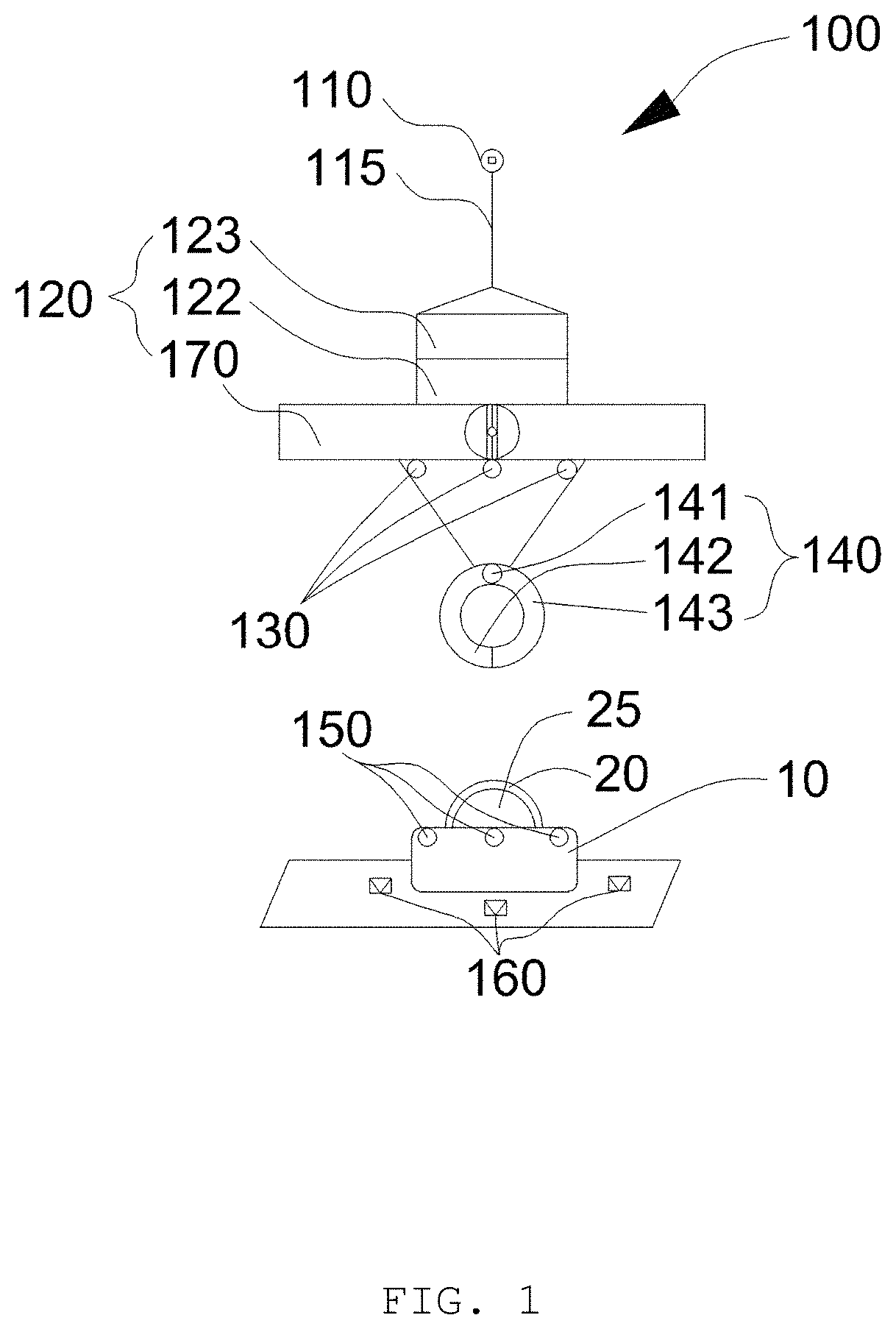

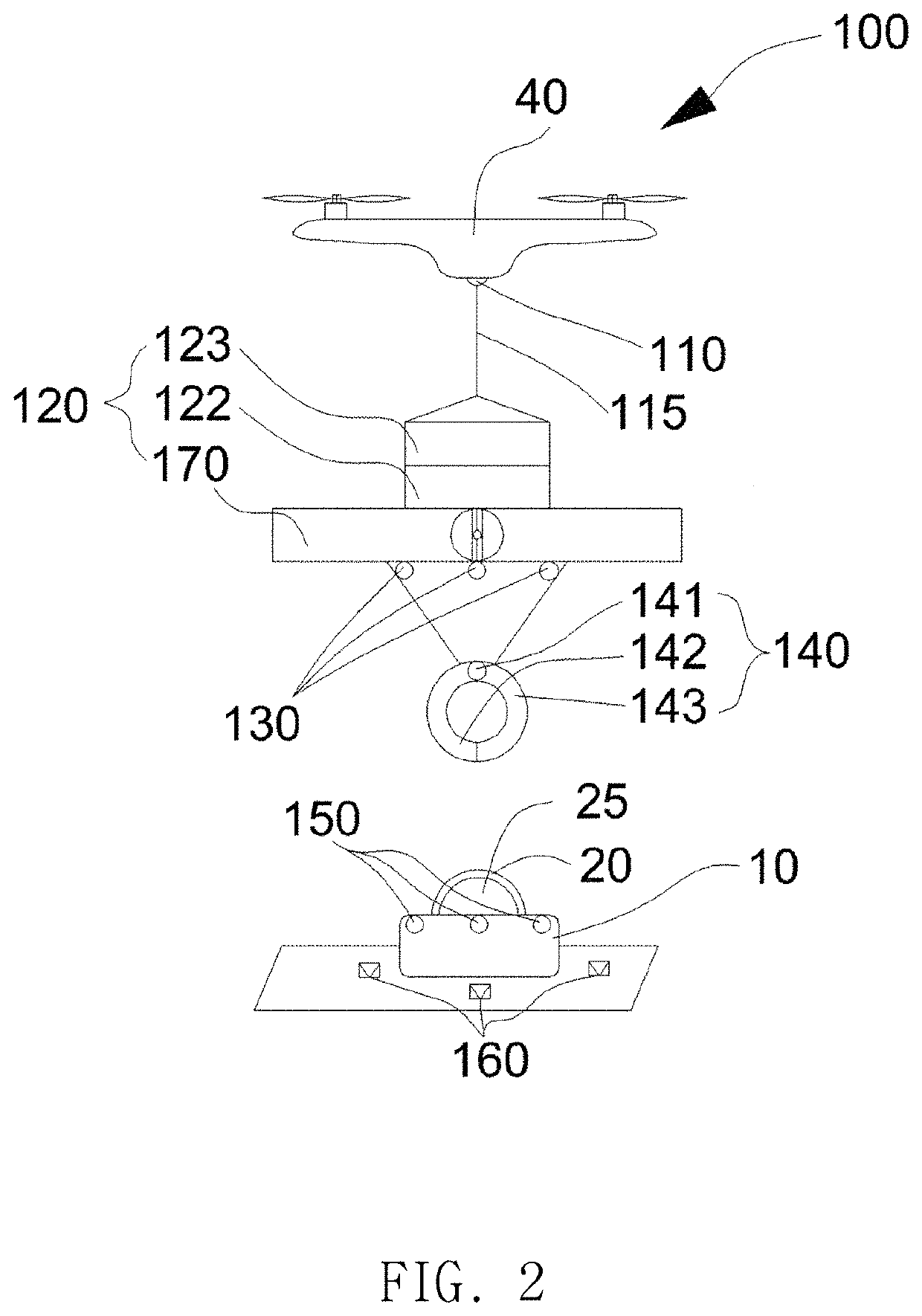

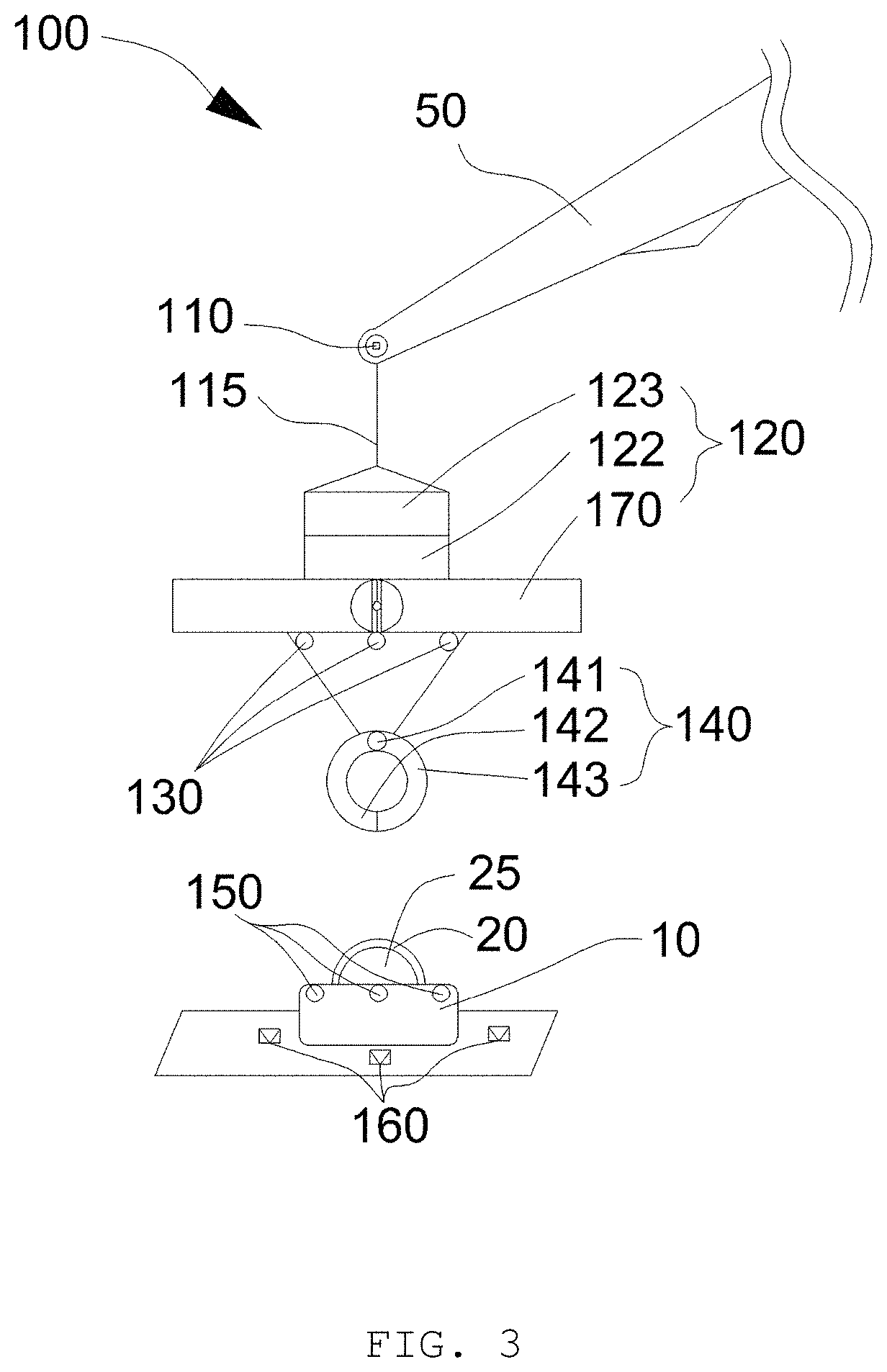

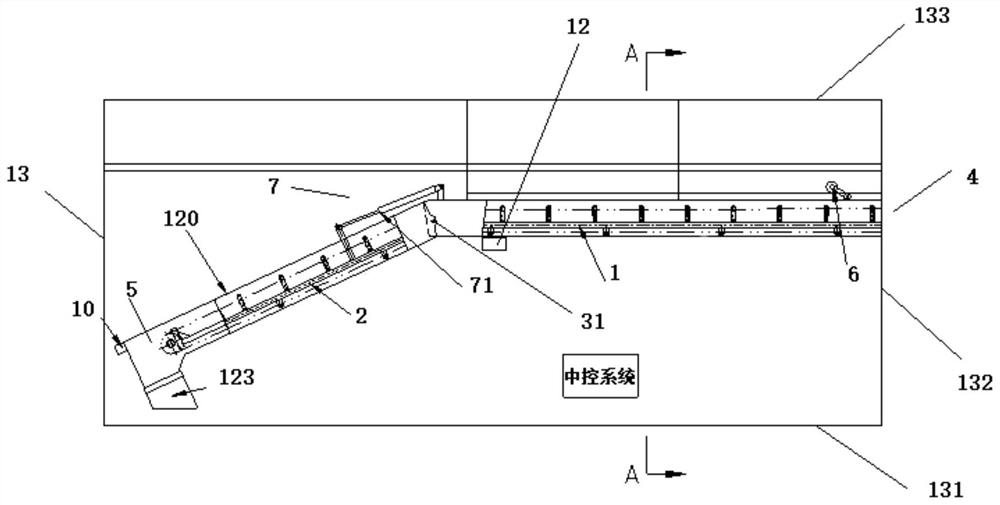

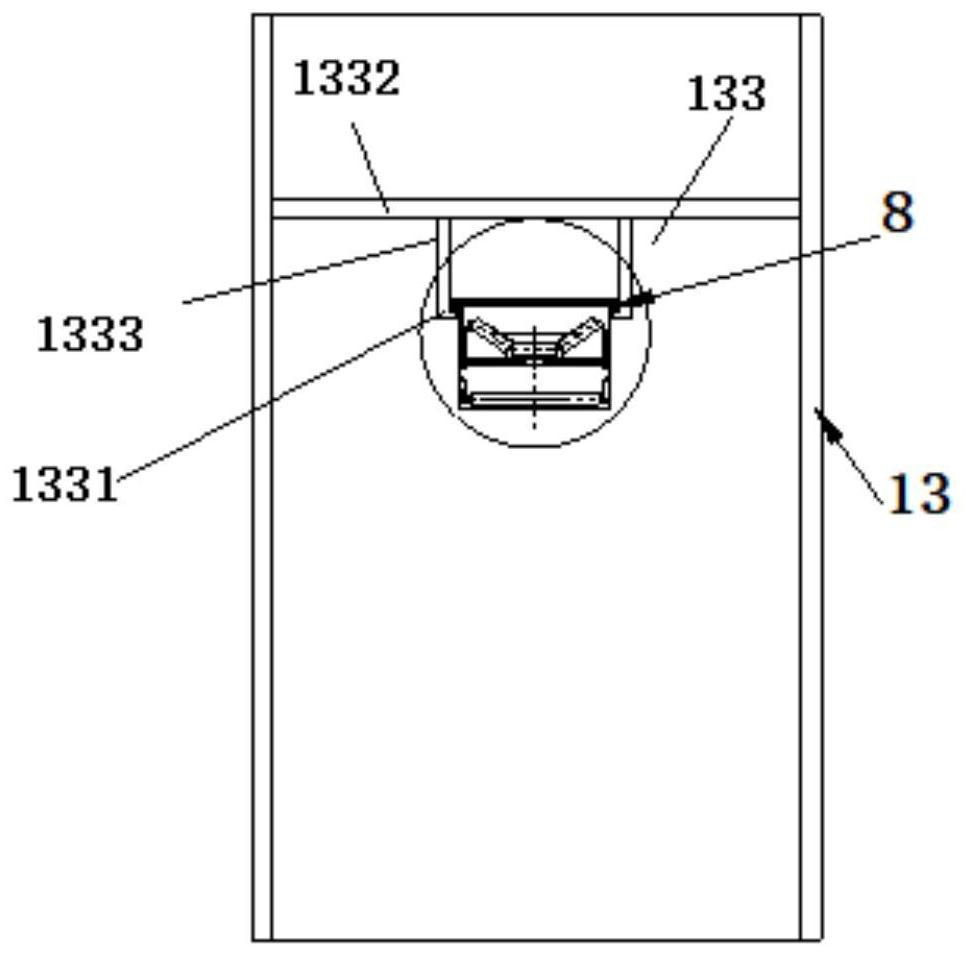

Unmanned automated hook coupling device

ActiveUS20190152600A1Easy to trackPrecise unloadingAircraft componentsUnmanned aerial vehiclesCouplingMonitoring system

Disclosed is an unmanned automated hook-fastening device including a device coupler, a propulsion unit, a transmitter, a receiver, hook pliers, and an unloading transmitter. The propulsion unit adjusts the position of the hoisting unit with respect to the object, on the basis of the position signal transmitted by the transmitter and received by the receiver, and adjusts the position of the hoisting unit coupled to the object, on the basis of the position signal transmitted by the unloading transmitter and received by the receiver. It is possible to easily track the position of a hook of the object to be hoisted, automatically fasten the hook pliers to the hook, and automatically fasten the hook to a crane without a monitoring system.

Owner:VESSEL AEROSPACE CO LTD

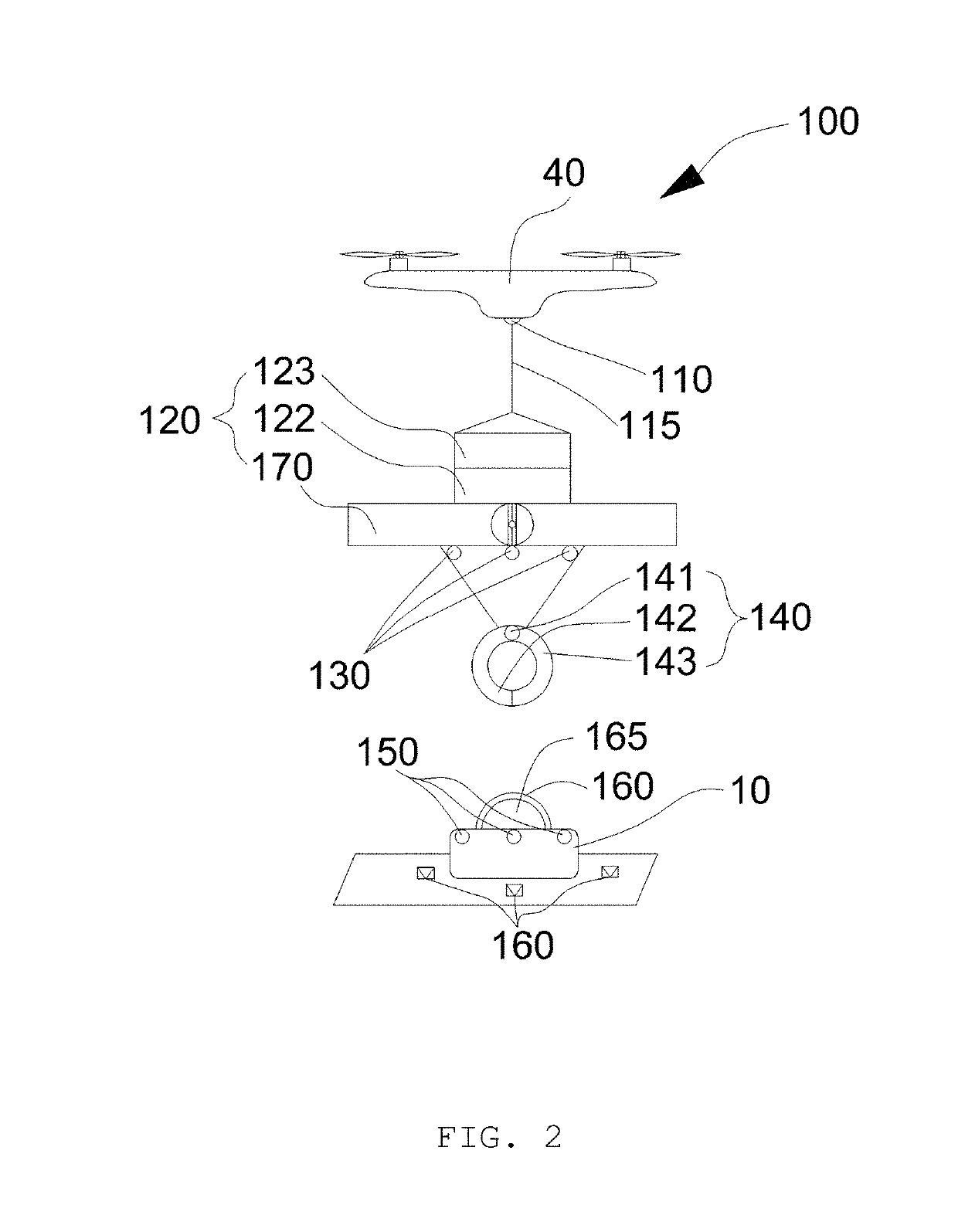

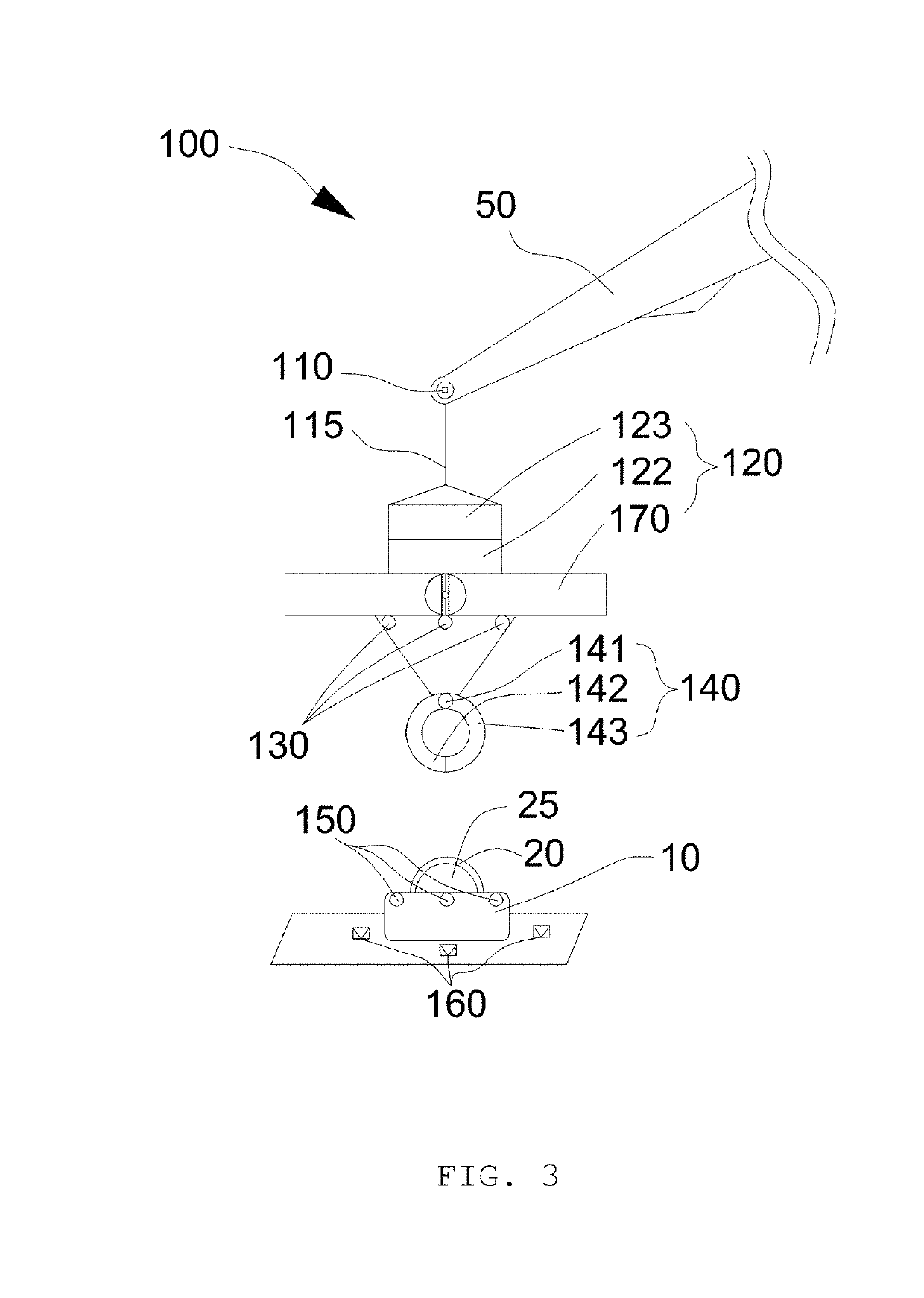

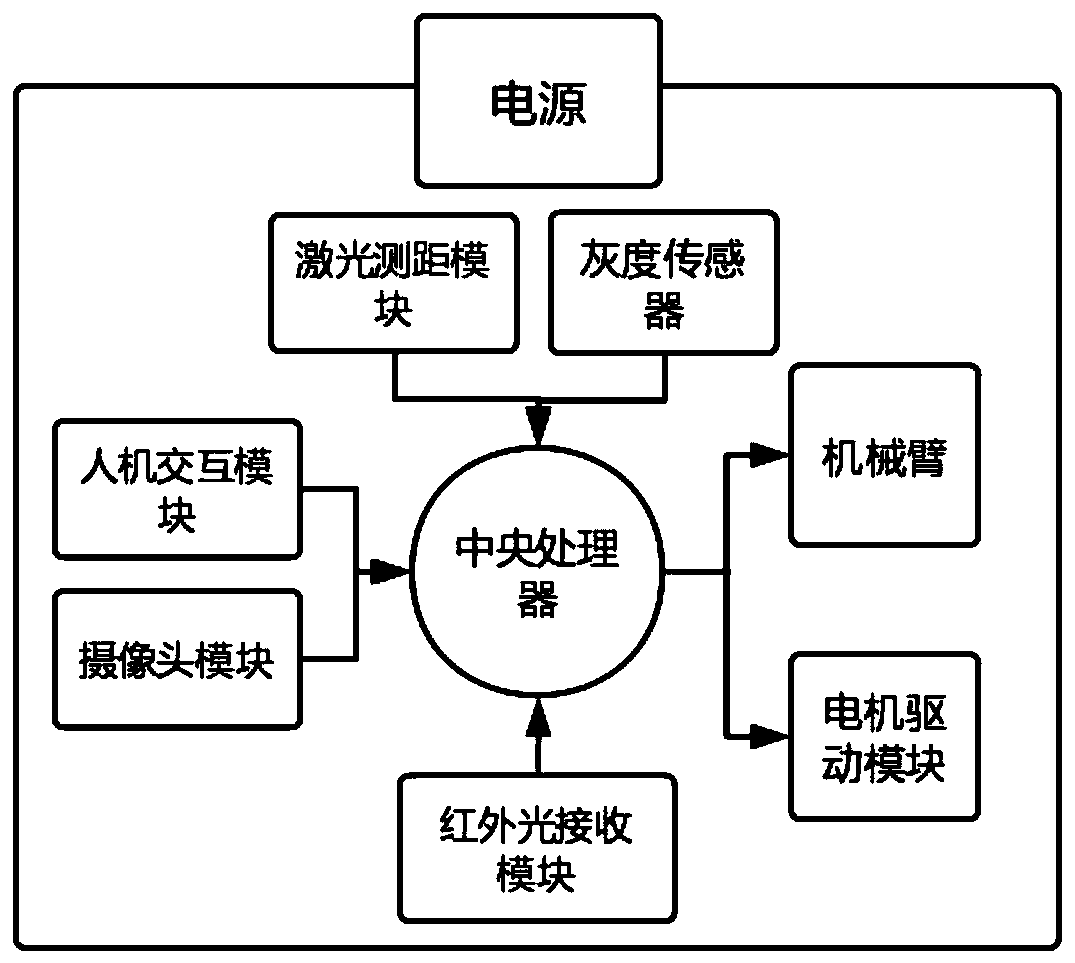

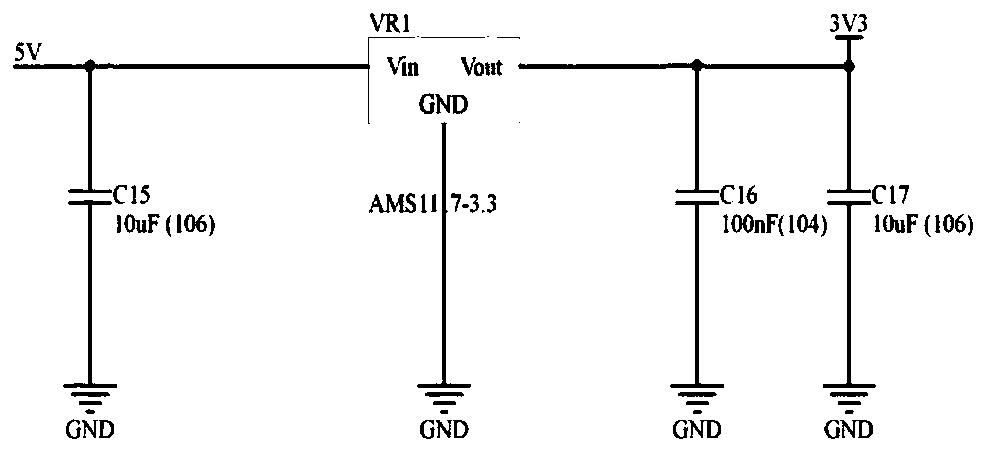

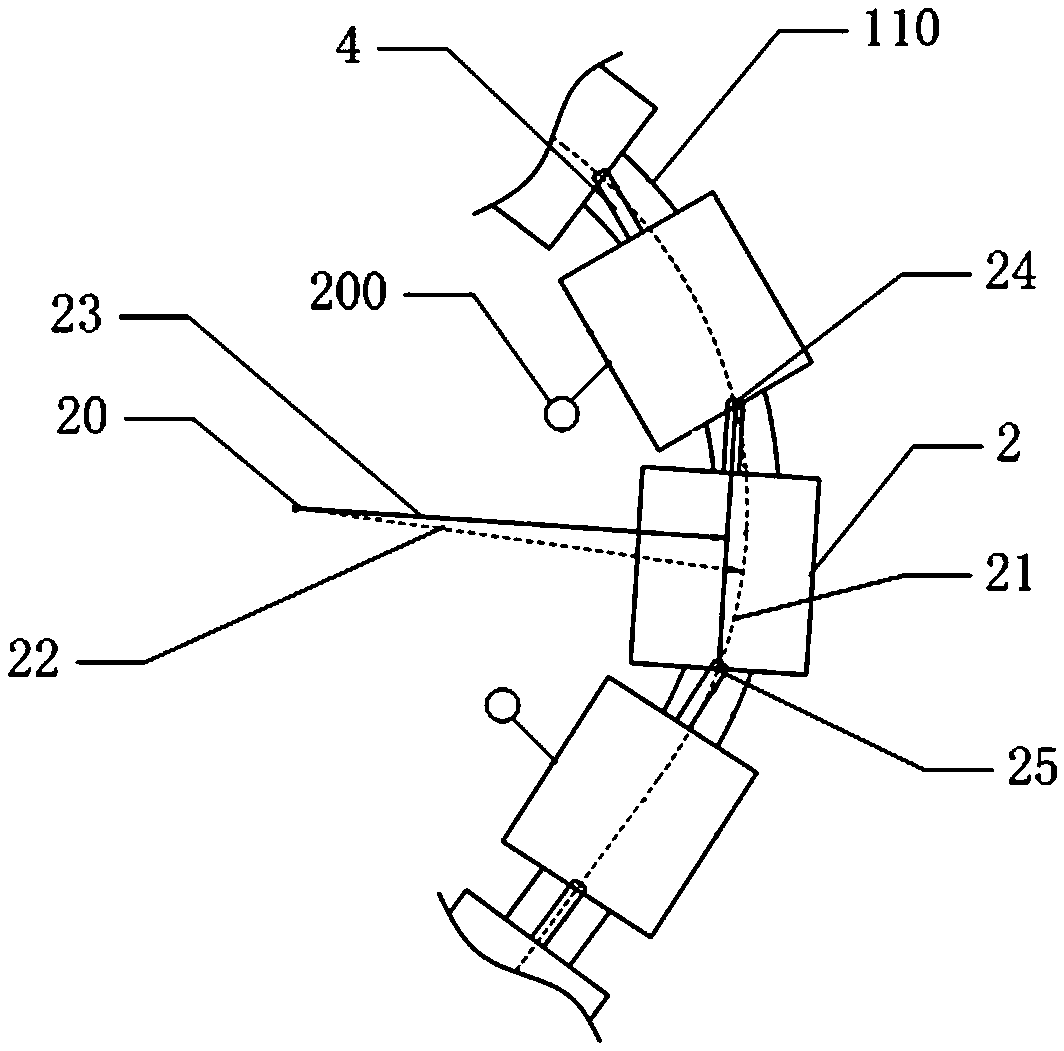

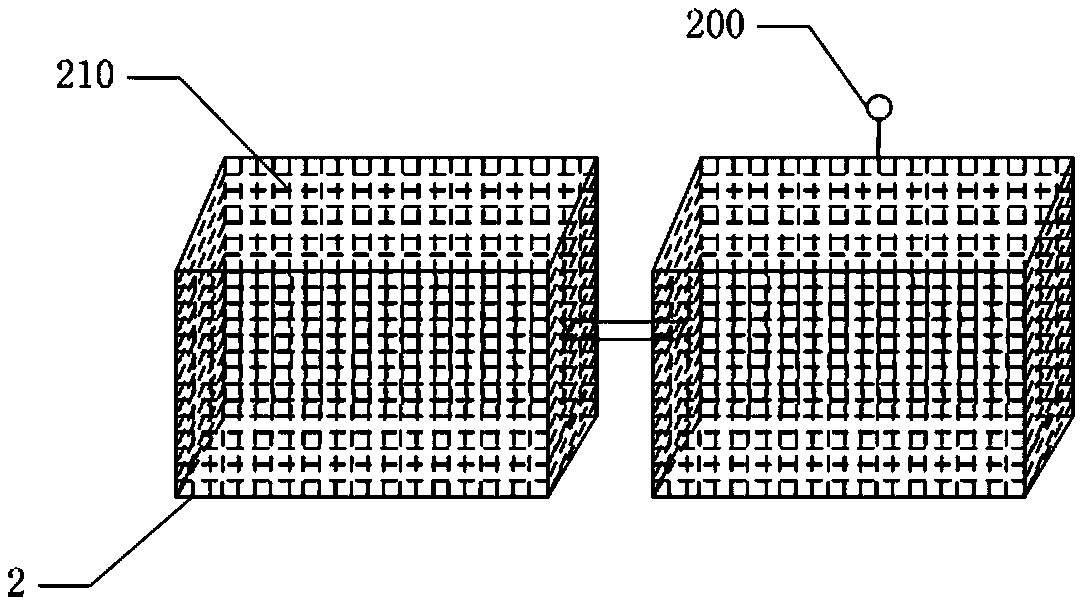

Intelligent tracking carrying trolley with mechanical arm

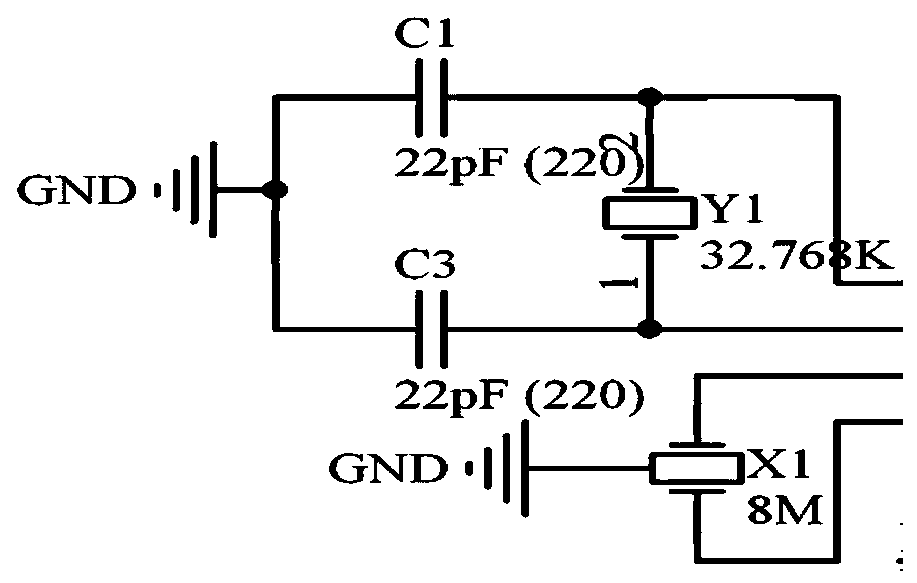

PendingCN109794921AFlexible and stable handlingAccurate loading and unloadingProgramme-controlled manipulatorVehiclesAutomatic controlHigher Power

The invention discloses an intelligent tracking carrying trolley with a mechanical arm, and belongs to the technical field of automatic control. The intelligent tracking carrying trolley with the mechanical arm comprises a bottom plate, a high-power direct current speed reduction motor, a driving mechanism, a monitoring mechanism, the mechanical arm and a main control panel. External control information is received through an infrared receiving module and transmitted to a central processing unit, the central processing unit commands the mechanical arm to perform the action to carry materials,then a camera is utilized to identify whether carrying is successful or not, and if not, the mechanical arm changes the action to continue loading; and later, the trolley carry out tracking accordingto the ground information collected by a gray level sensor, a laser ranging module judges whether there are obstacles ahead or not, after the trolley arrives at the designated place, the central processing unit instructs the mechanical arm to lay down the materials, and the function of carrying the materials is realized. The intelligent tracking carrying trolley with the mechanical arm is high inintelligentization degree, flexible to carry and extremely high in stability, improves the carrying efficiency of the materials and provides experience for follow-up factory workshop automation.

Owner:DALIAN UNIV OF TECH

Apparatus to make decorations on prefabricated water-proofing bitumen-mix membranes and corresponding plant for the production of said prefabricated water-proofing membranes

ActiveUS20160332191A1Simplify production complexityLow costLiquid surface applicatorsRoof covering using flexible materialsSolid particleBiomedical engineering

Apparatus to make decorations on a prefabricated water-proofing bitumen-mix membrane, wherein the decorations are made by depositing solid particles, in the form of flakes, grains, sand or grit, suitable to adhere to at least one surface of said prefabricated water-proofing bitumen-mix membrane. The apparatus comprises at least one transfer member provided with a support surface suitable to receive, support and transfer the solid particles toward the surface to be enhanced of the prefabricated water-proofing bitumen-mix membrane. The support surface is provided with a plurality of cavities suitable to receive the solid particles. The cavities are made inside at least one surface portion of the support surface and the surface portion, essentially reproducing the shape and sizes of at least one of the decorations.

Owner:BOATO INT S P A A SOCIO UNICO

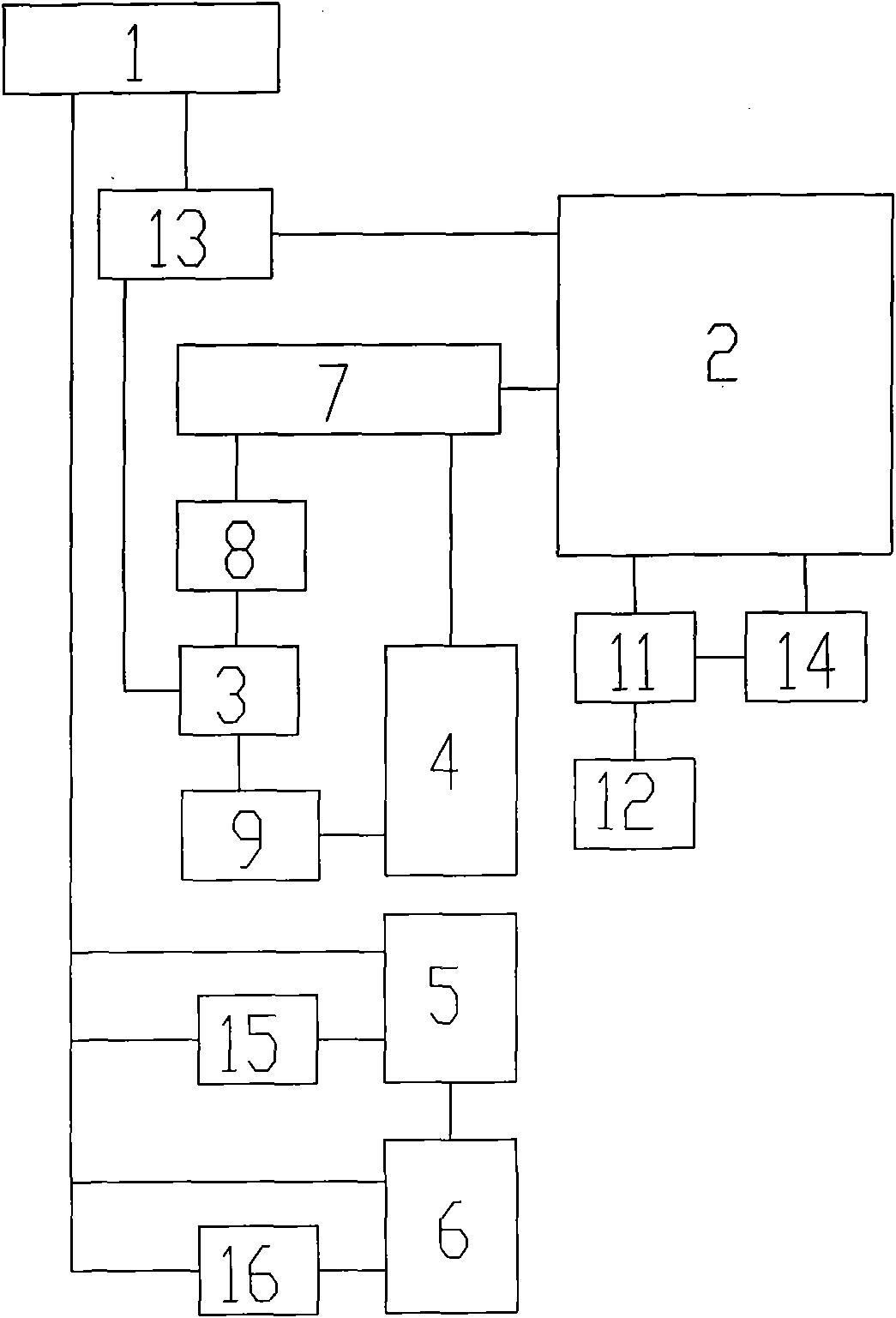

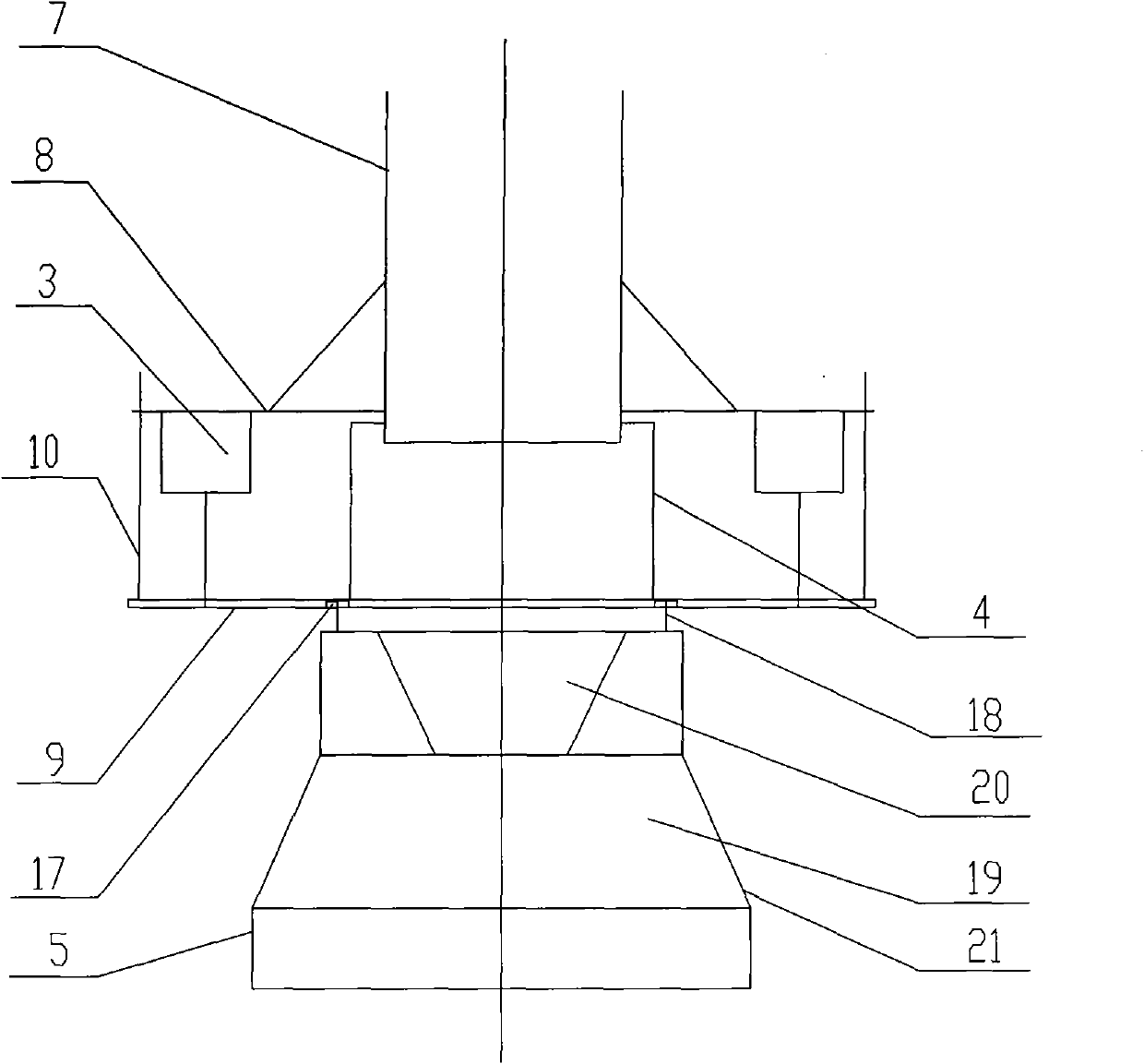

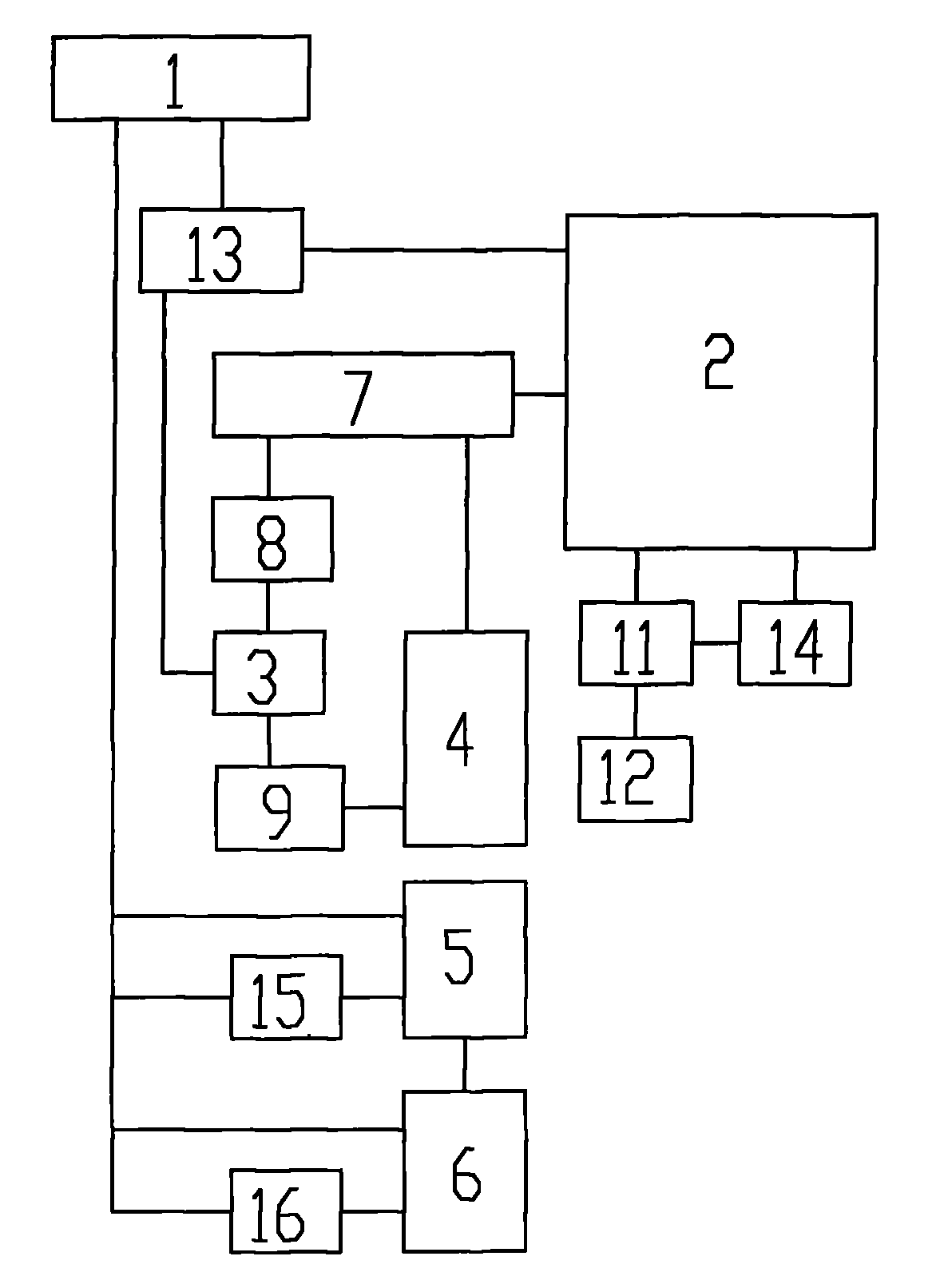

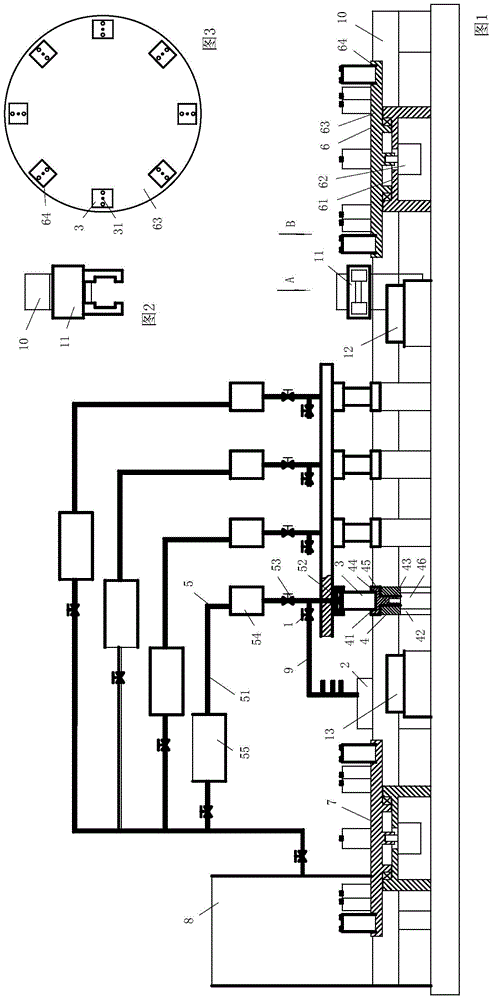

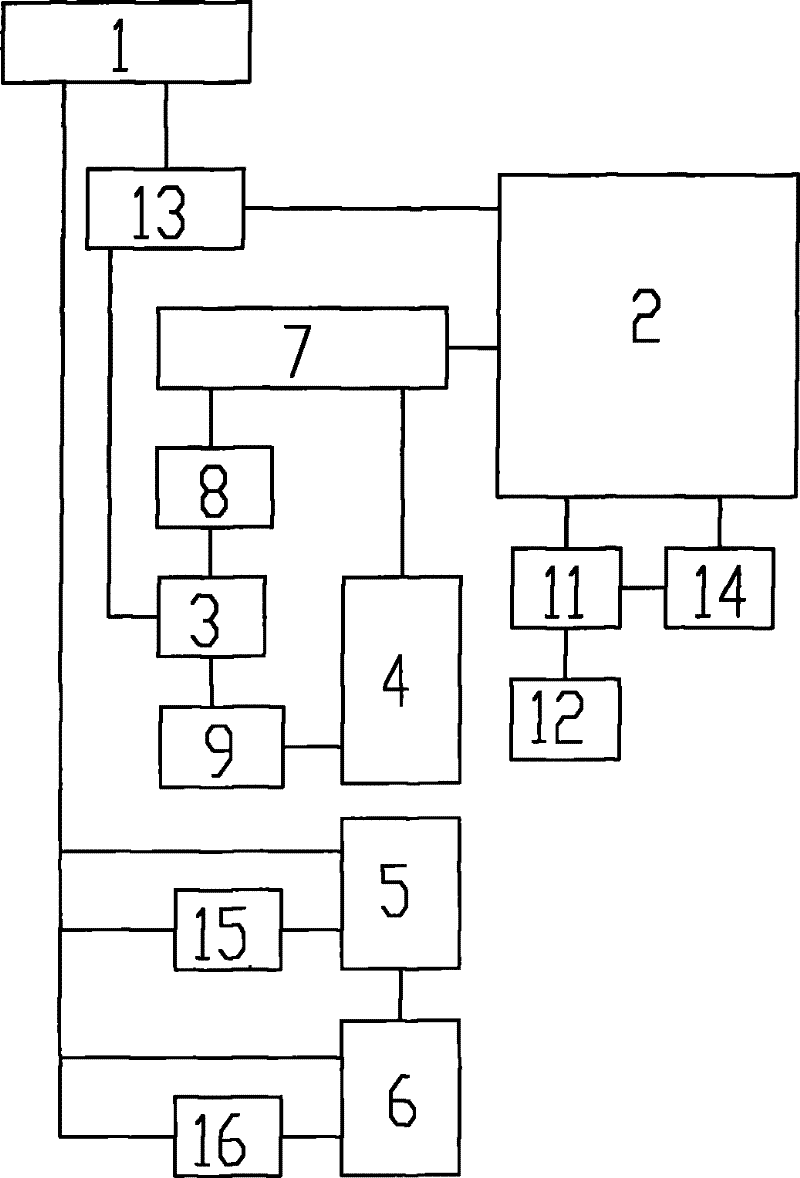

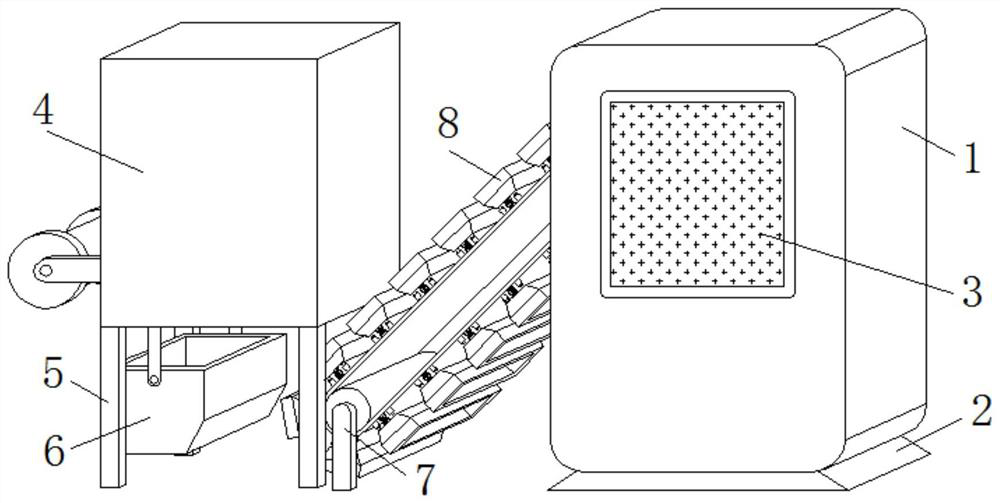

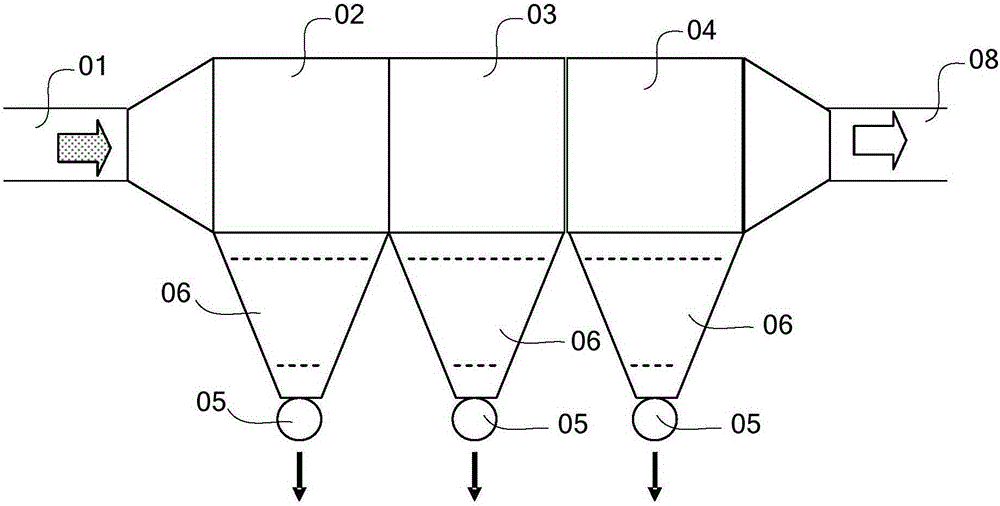

Dedusting equipment and method for fixed-point unloading movable dumper

ActiveCN102085966AImprove working environmentSolve the problem of dustLoading/unloadingAutomatic controlDrive wheel

The invention relates to the technical field of unloading and dedusting bulk materials, in particular to dedusting equipment and a dedusting method for a fixed-point unloading movable dumper. The equipment comprises a central control room movable dumper, a feeding groove, a storage bin, a hanger plate, an electromagnet, a lower seat, a guide rod and a telescopic dustproof cover, wherein an automatic control system, a dumper encoder, two frequency conversion driving devices, two driving wheels with reverse taper directions, a feeding groove encoder, a level gage, a dustproof cover on the upper side of the feeding groove, an outer barrel in an inverted funnel shape, an inner barrel in a funnel shape, and rigid sealing strips are arranged in the movable dumper. The dedusting method comprises the following steps that: a central control room operates the movable dumper to move, align, stop, unload and move away through the automatic control system on the movable dumper according to information transmitted by the level gage in each storage bin. Through the invention, energy is saved and emission is reduced when the movable dumper unloads materials, automatic control is convenient to realize, the working efficiency of the equipment is improved, the working environment of a worker is improved, and investment is saved.

Owner:ANSTEEL GRP MINING CO LTD

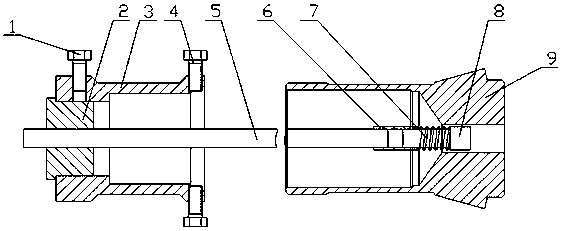

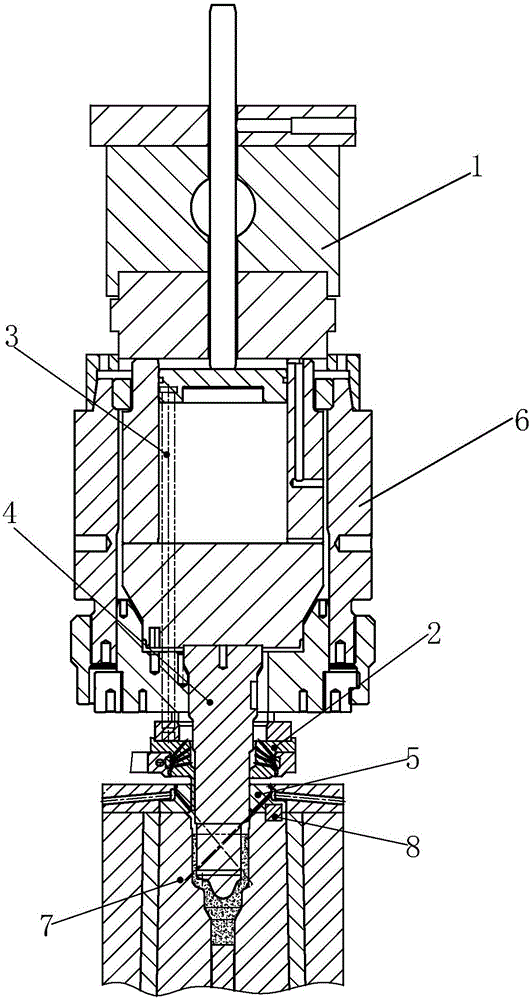

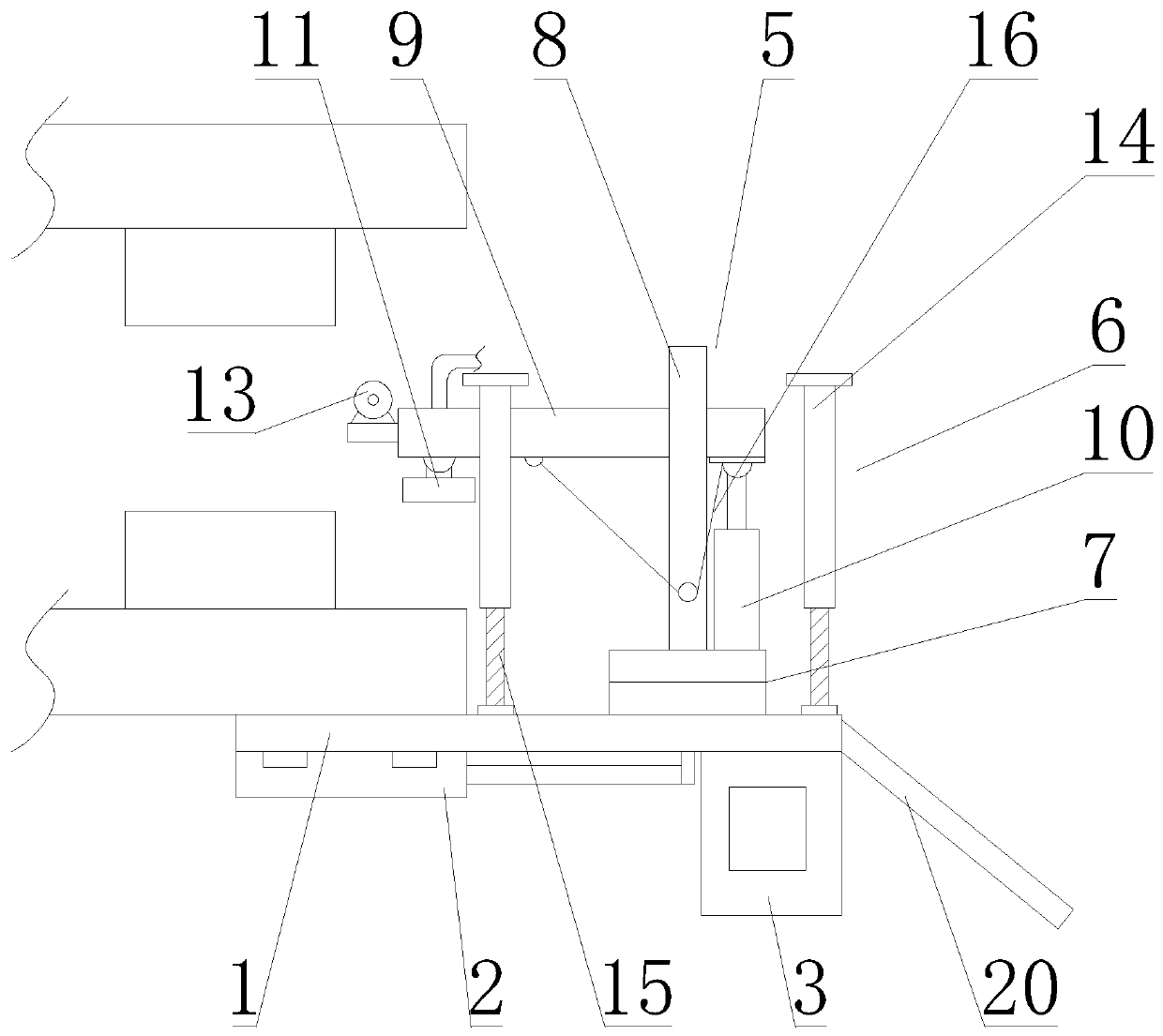

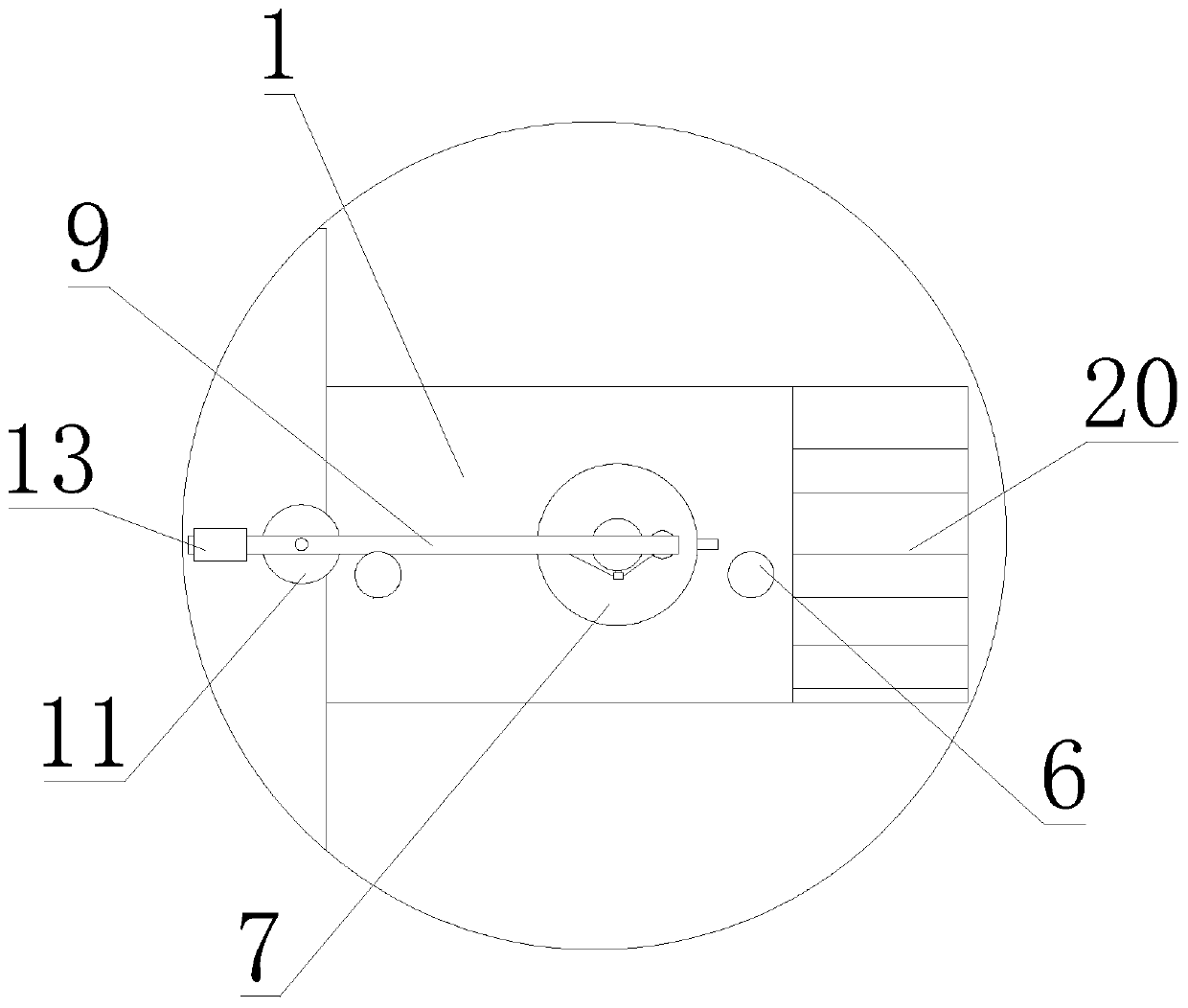

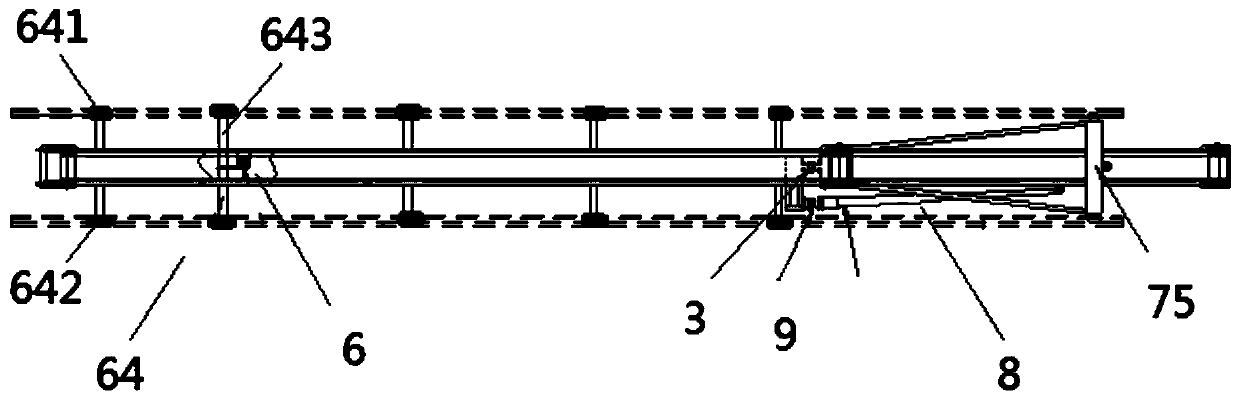

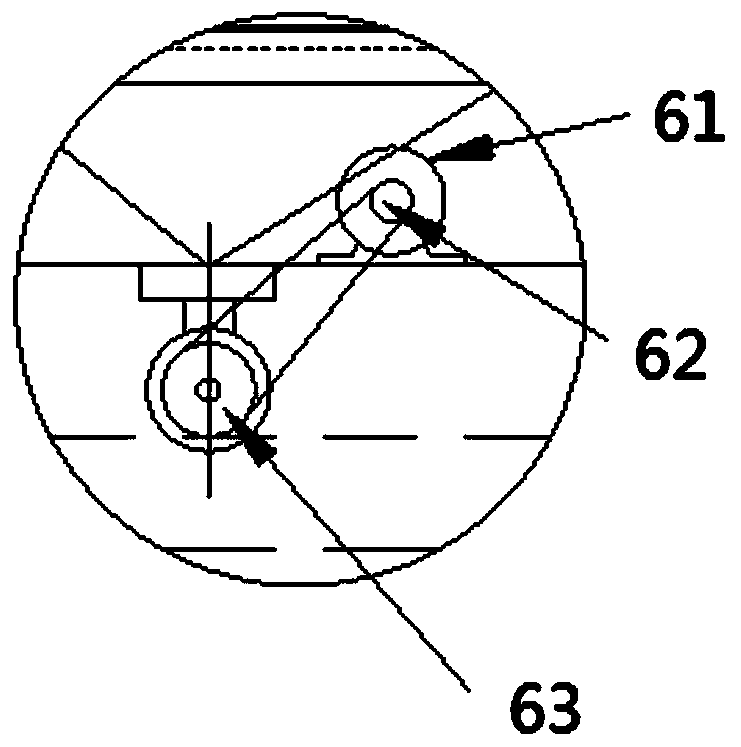

Device used for accurate rear location and rapid unloading for numerically-controlled lathe

InactiveCN107824808APrecise positioningPrecise unloadingAutomatic workpiece supply/removalMetal working apparatusMechanical engineering

The invention discloses a device used for accurate rear location and rapid unloading for a numerically-controlled lathe. The device comprises a location assembly, an ejection rod (5) and an unloadingassembly, wherein the location assembly and the unloading assembly are installed on the front part and the rear part of the ejection rod (5) separately. The device is characterized in that a locationdevice comprises an outer sleeve (3) and a clamping block (2), the clamping block (2) is installed on the front part of the outer sleeve (3) in a sleeving manner, a plurality of bolts B (4) are installed on the rear part of the outer circumferential surface of the outer sleeve (3), and the ejection rod (5) is installed in a through hole of the clamping block (2) and penetrates through the cavity of the outer sleeve (3); and an unloading device comprises a sleeve pipe (6), a spring (7) and a pusher (8), the rear end of the ejection rod (5) is installed on the front half part in the sleeve pipe(6), the pusher (8) is installed on the rear half part in the sleeve pipe (6), and the spring (7) is installed outside the pusher (8) in a sleeving manner. The device disclosed by the invention is accurate, efficient and stable, and suitable for the popularization and use of accurate rear location and rapid unloading for the numerically-controlled lathe.

Owner:AVIC STANDARD PARTS MFG

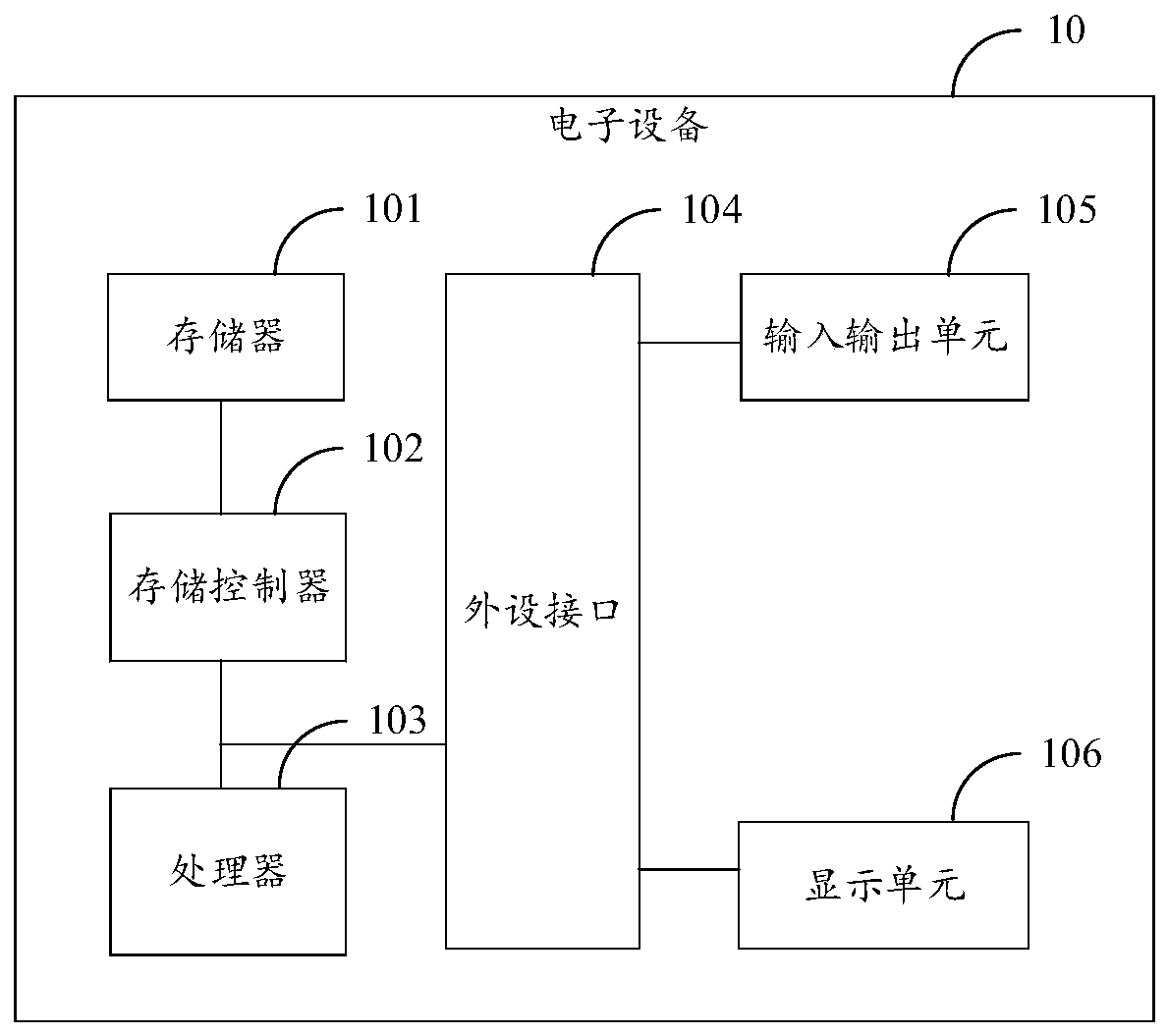

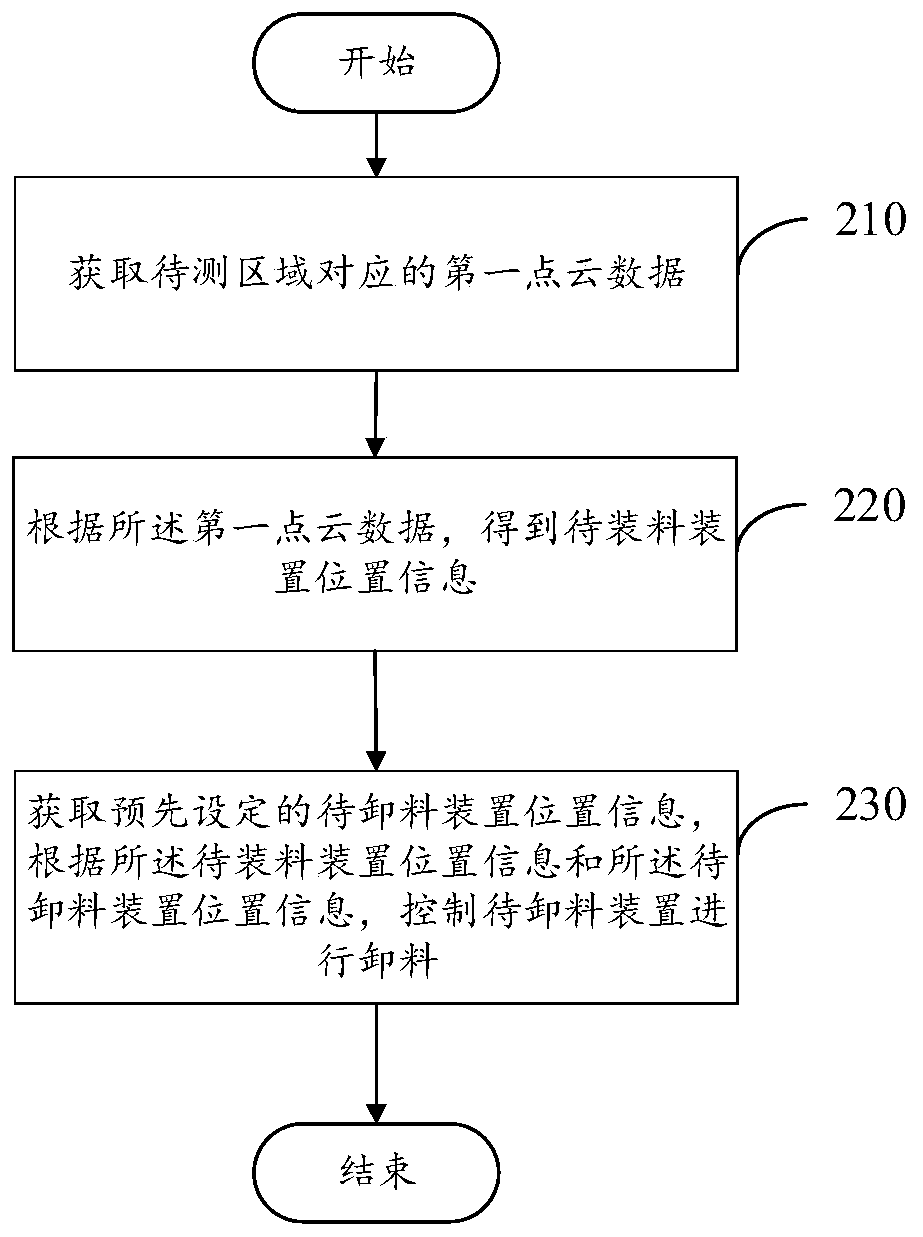

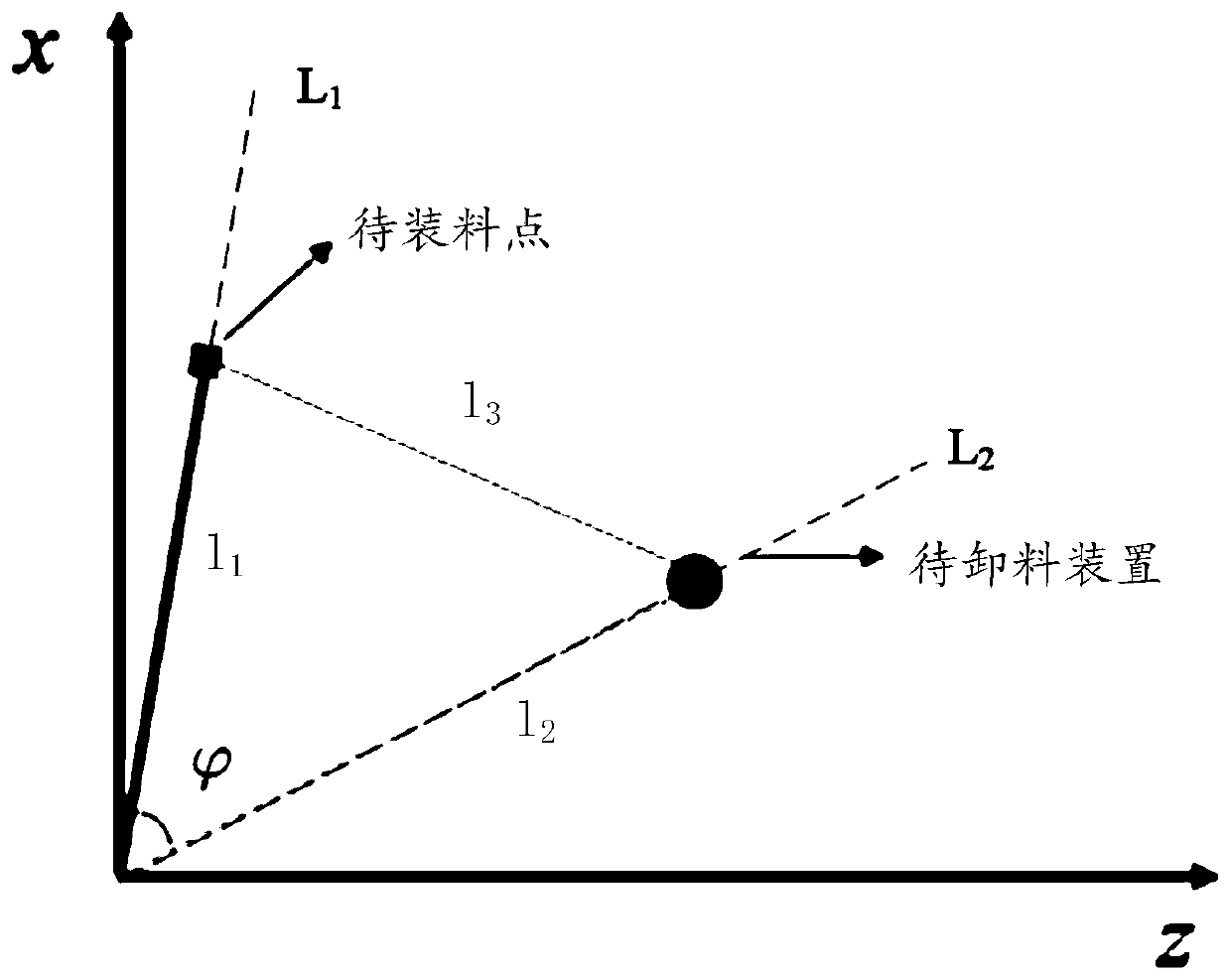

Discharge method, discharge controller, excavator, electronic equipment, and storage medium

ActiveCN110080326APrecise positioningPrecise unloadingSoil-shifting machines/dredgersDischarge efficiencyPoint cloud

The embodiment of the invention provides a discharge method, a discharge controller, an excavator, electronic equipment, and a storage medium. The method comprises the steps that first point cloud data corresponding to a to-be-detected area is obtained; according to the first point cloud data, to-be-charged position information is obtained; and preset to-be-discharged device position information is obtained, and a to-be-discharged device is controlled to discharge according to the to-be-charged position information and the to-be-discharged device position information. The first point cloud data is obtained through a data acquisition device so as to obtain the to-be-charged position information, and the to-be-discharged device is controlled to discharge according to the preset to-be-discharged device position information. Therefore, automation of the discharge process is achieved, the to-be-charged position is accurately located, discharge is carried out more effectively and accurately,the discharge time is shortened, and the discharge efficiency is improved.

Owner:北京拓疆者智能科技有限公司

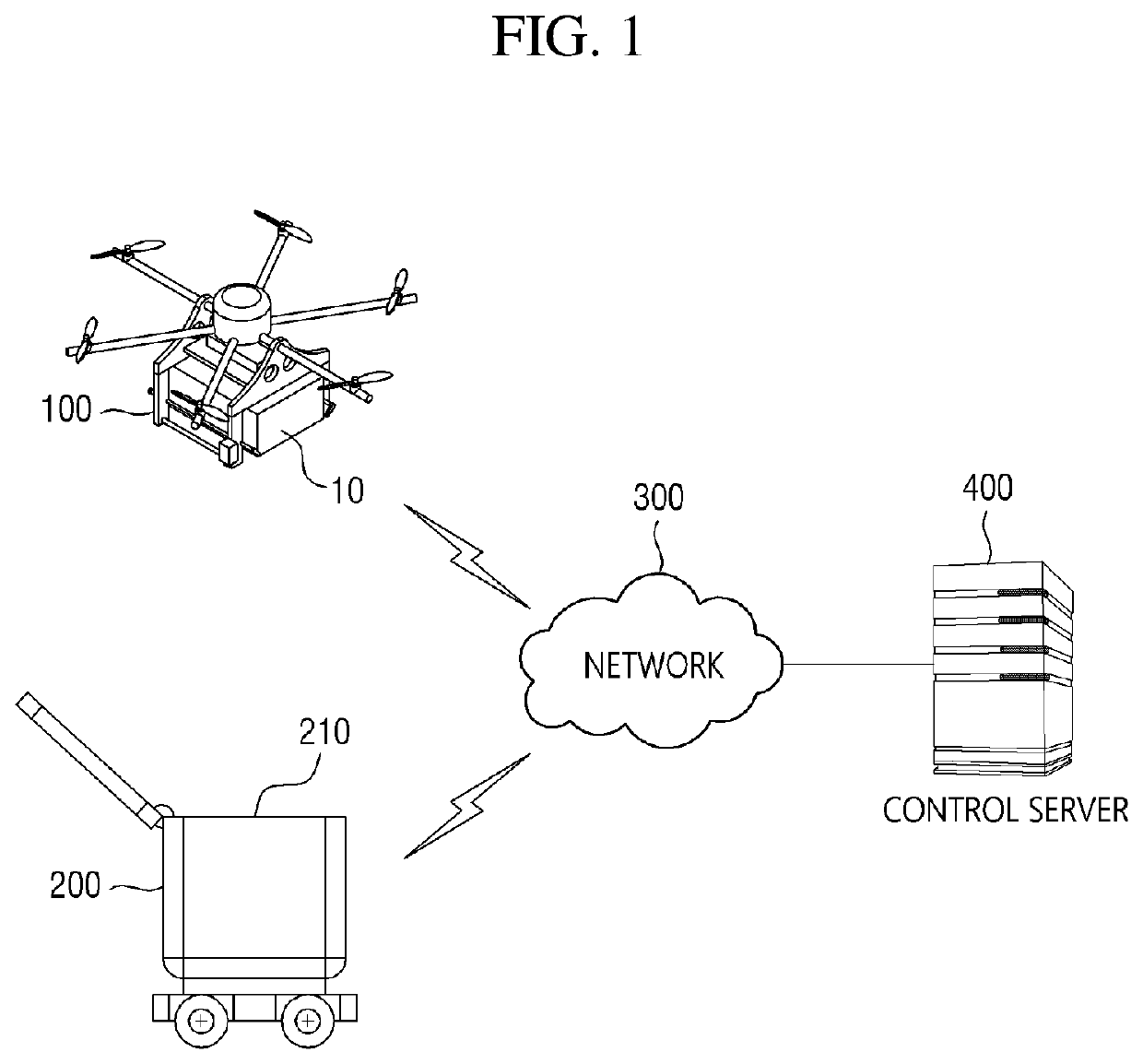

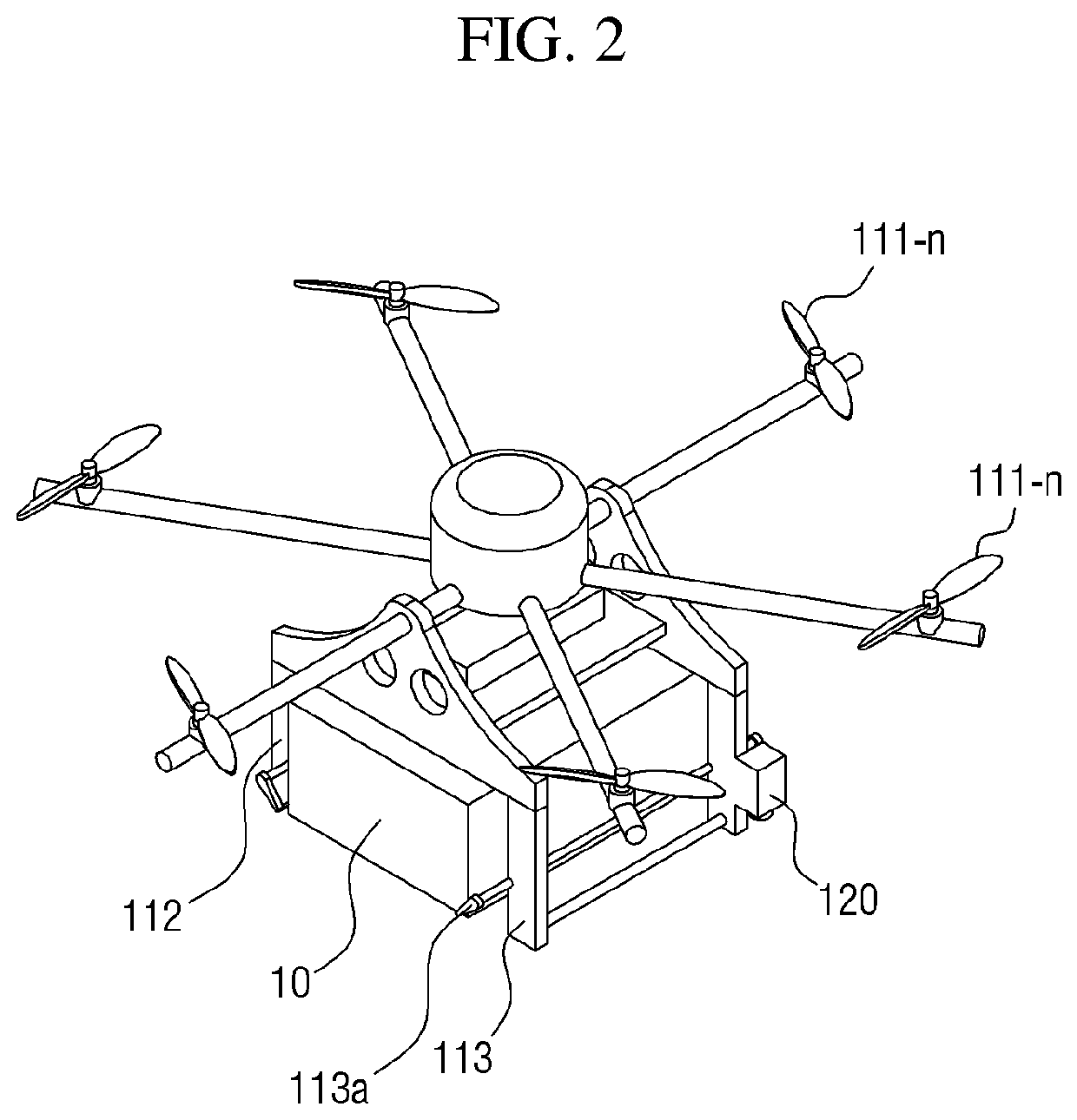

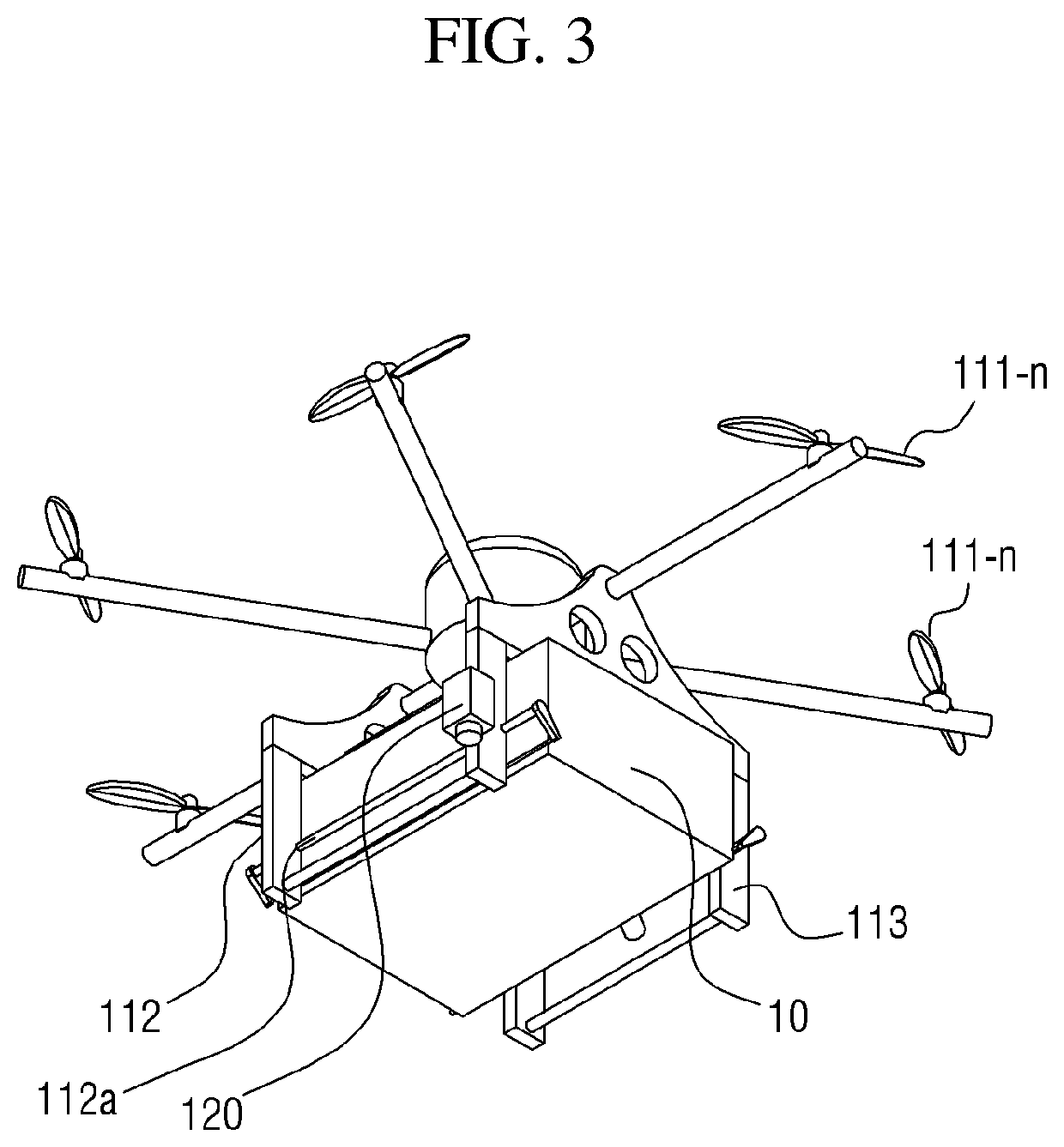

Method and apparatus for handling goods by unmanned aerial vehicle and autonomous vehicle

ActiveUS11334078B1Easy to adjustPrecise unloadingAircraft componentsProgramme-controlled manipulatorFlight vehicleUncrewed vehicle

Provided is a method for an unmanned aerial vehicle to handle goods in cooperation with an autonomous vehicle. The method comprises capturing, by the unmanned aerial vehicle, an image of the autonomous vehicle having a goods storage box, recognizing, by the unmanned aerial vehicle, a marker displayed in the goods storage box by analyzing the captured image, identifying, by the unmanned aerial vehicle, a region occupied by the marker on the captured image, adjusting a relative position of the unmanned aerial vehicle and the autonomous vehicle, wherein the marker displayed in the goods storage box is covered by a lid of the goods storage box and placed in a state that cannot be captured by the unmanned aerial vehicle, and the marker is exposed in a state that can be captured by the unmanned aerial vehicle only when the lid of the storage box is opened by communication between the unmanned aerial vehicle and the autonomous vehicle.

Owner:PABLO AIR CO LTD +1

Powdery admixture accurate weighing device

ActiveCN110260957AHigh precisionPrecise unloadingWeighing apparatus for materials with special property/formFrequency conversionEngineering

The invention relates to a powdery admixture accurate weighing device. The powdery admixture accurate weighing device comprises a weighing hopper, a weighing sensor, a bracket, a flexible steel wire rope, a weighing meter and a blanking device, wherein the weighing hopper is fixed on the bracket; the weighing sensor is arranged at the contact portion of the weighing hopper and the bracket, the bracket is suspended below the weighing meter through the flexible steel wire rope, and the blanking device is arranged in the weighing hopper; by adopting the suspension structure and the sandwich type composite damping structure of the bracket, the influence of vibration on the weighing precision of the admixture can be effectively avoided; by arranging two sets of weighing devices with different precisions and sensitivities, high-efficiency feeding and high-precision discharging can be achieved; by adopting a turn buckle to connect the weighing meter and the bracket, the weighing hopper can be quickly leveled, the weighing sensor is adopted to match with a feeding frequency conversion spiral machine and a discharge spiral ribbon to accurately control the weight of the discharge, and a rotating blade is adopted to stir powder in the weighing hopper to make blanking smooth.

Owner:ZHENGZHOU SANHE HYDRAULIC MACHINERY +4

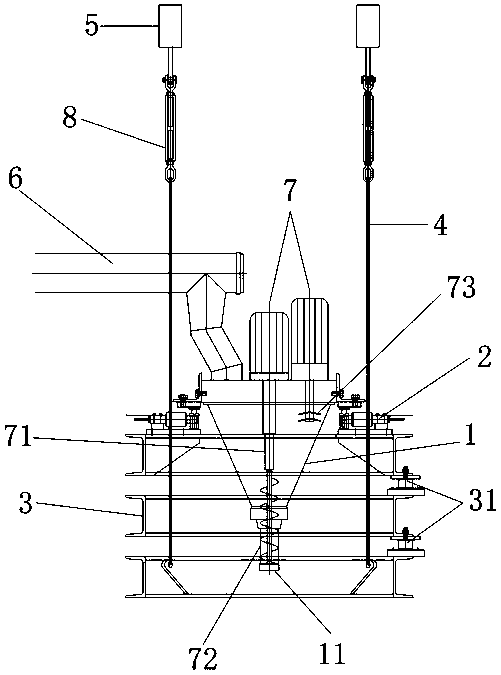

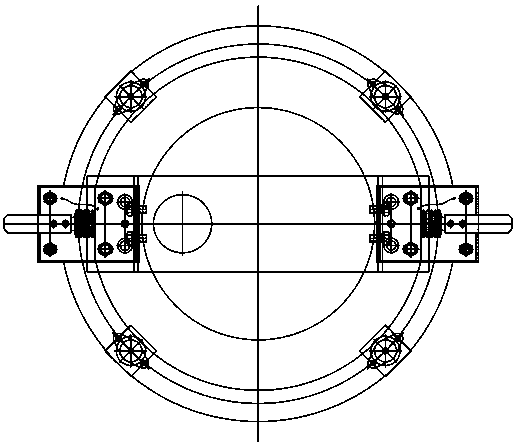

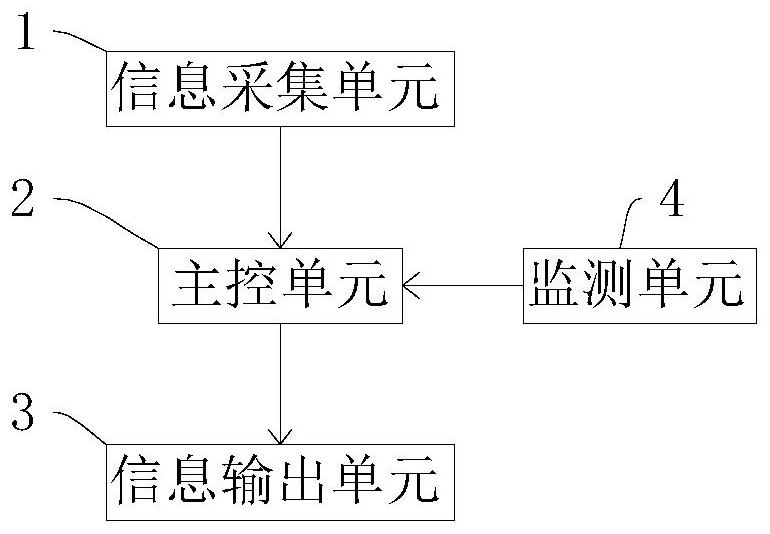

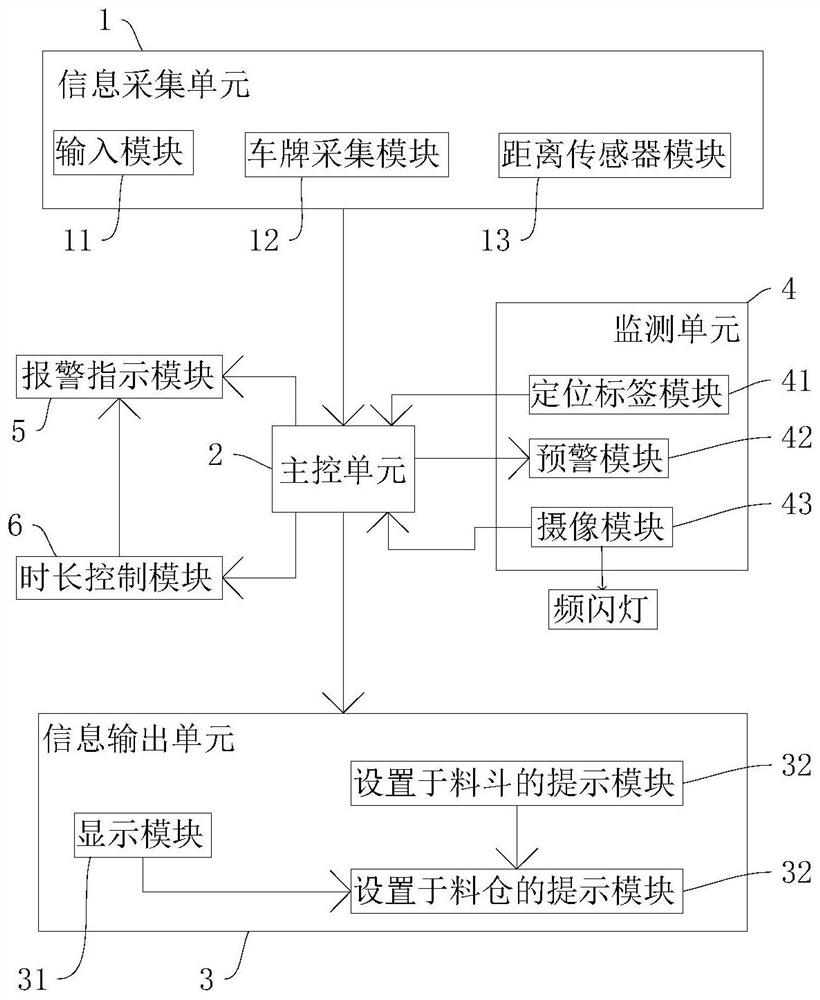

Intelligent mortar concrete aggregate supplementing error-proof system

PendingCN114654587AEasy to guideReduce the frequency of communicationMixing operation control apparatusRoad vehicles traffic controlProduction lineRelevant information

The invention provides an intelligent mortar concrete aggregate supplementing anti-error system, which comprises an information acquisition unit, a main control unit and an information output unit, and is characterized in that the main control unit is connected with the information acquisition unit and the information output unit at the same time; the information acquisition unit is used for acquiring and sending truck related information and forklift related information to the main control unit; the main control unit is used for storing and processing the information uploaded by the information acquisition unit and generating information which is fed back to the information output unit to be output by the information output unit; the information output unit is used for outputting the license plate number of a truck, the type of aggregate carried by the truck and the production line number and the stock bin number corresponding to the type of the aggregate, and outputting the number of a material lacking hopper and the stock bin number corresponding to the hopper number. The device has the effect that the problem that in the prior art, when a truck transports aggregate into a stock bin or a forklift supplements the aggregate into a hopper, mistaken loading exists, and consequently product quality accidents occur occasionally is solved.

Owner:重庆众联建筑科技有限公司

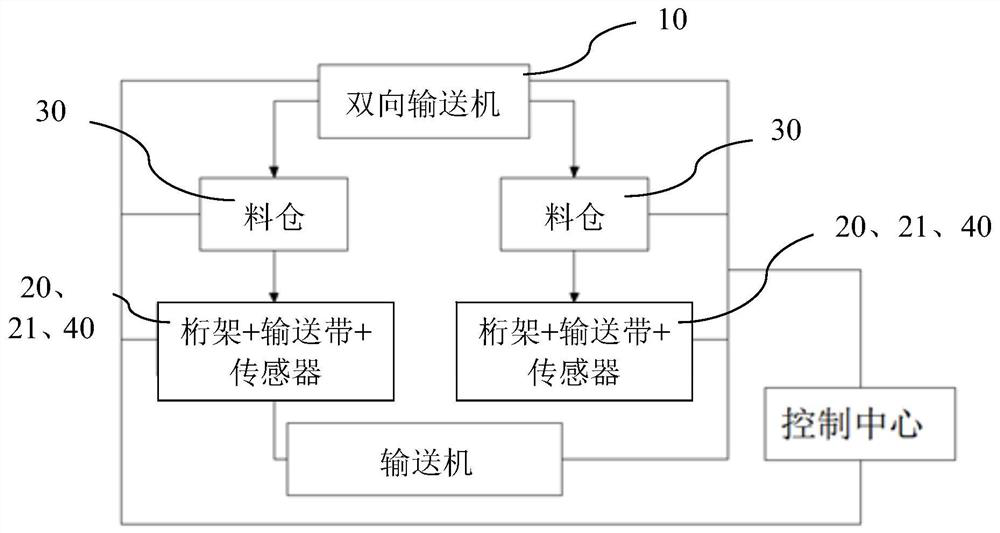

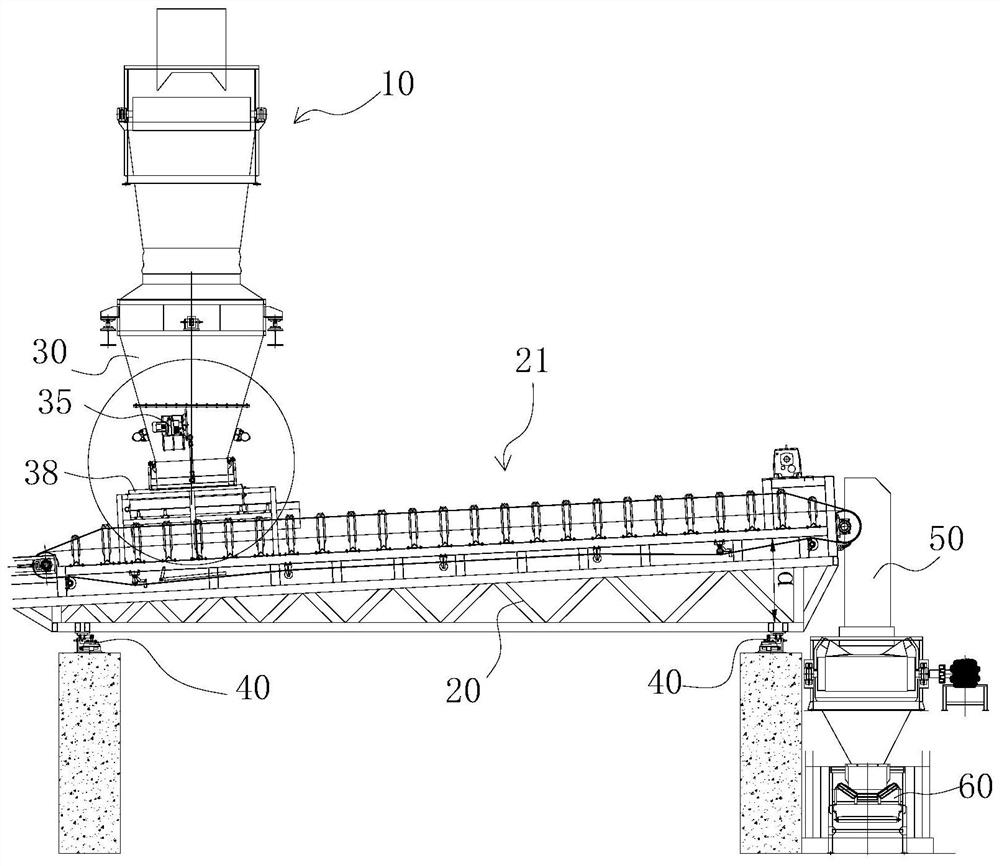

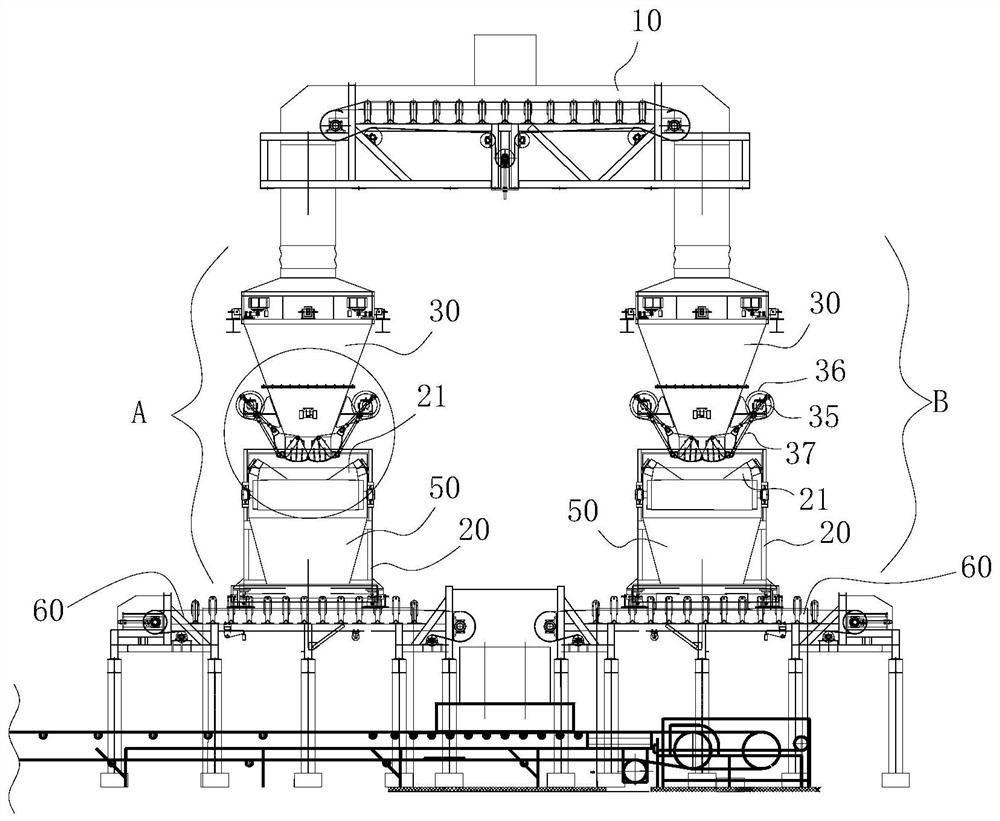

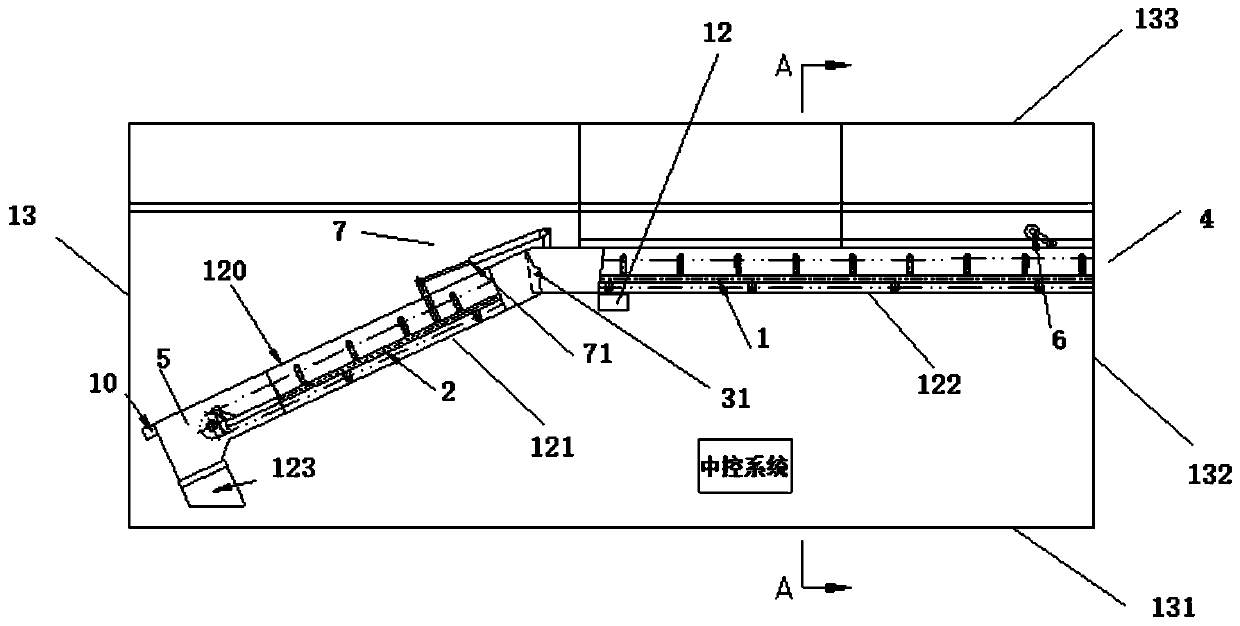

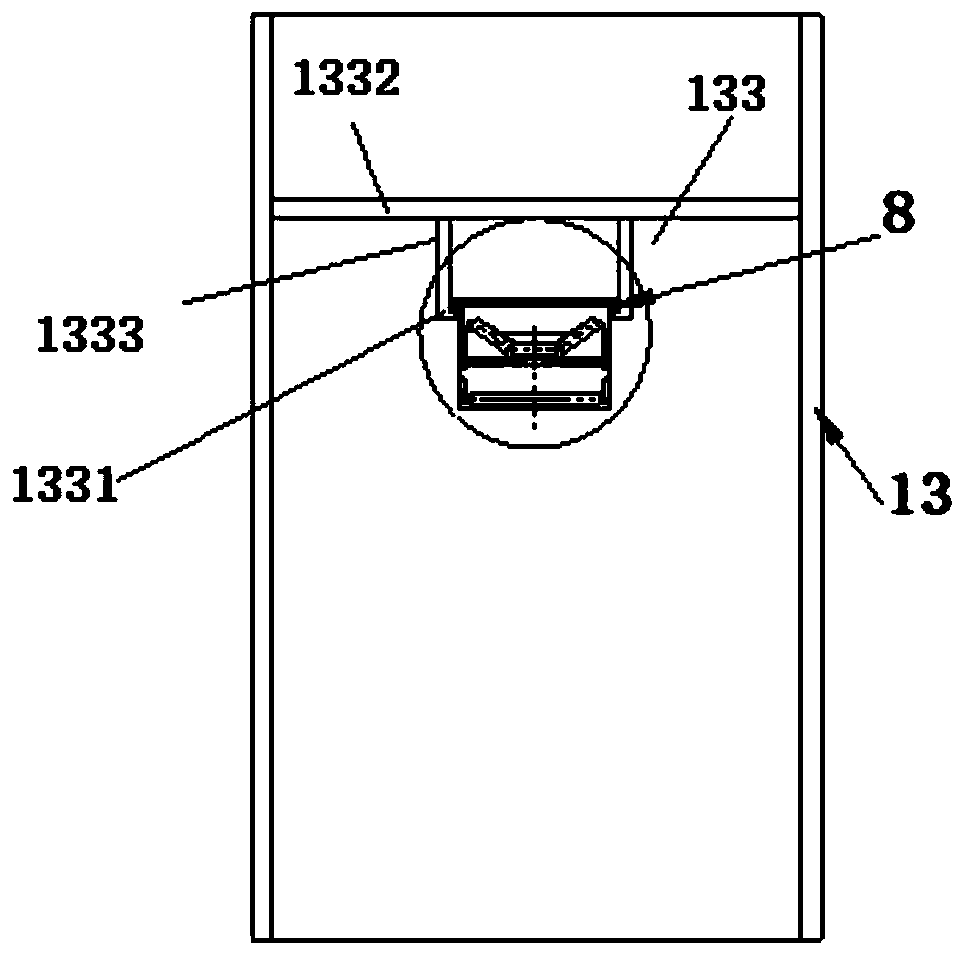

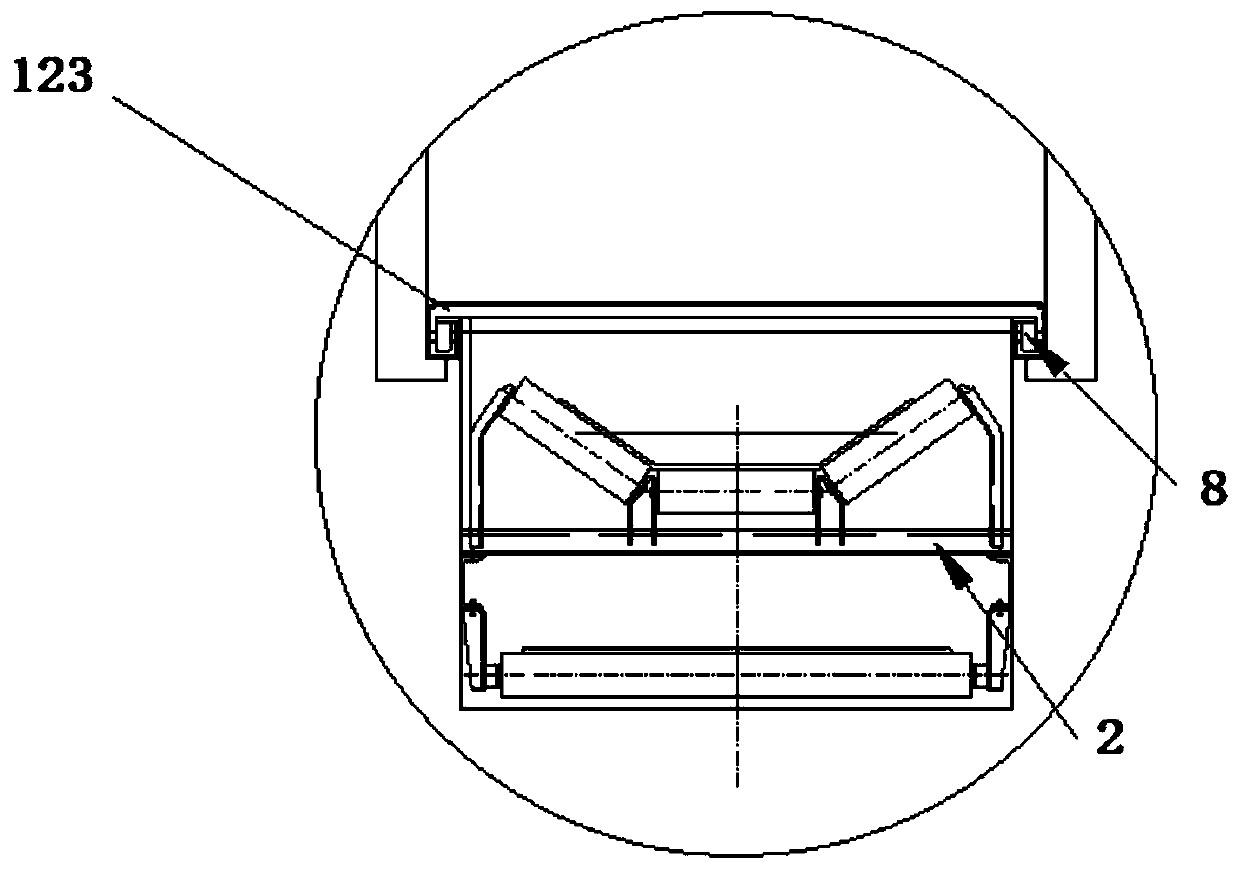

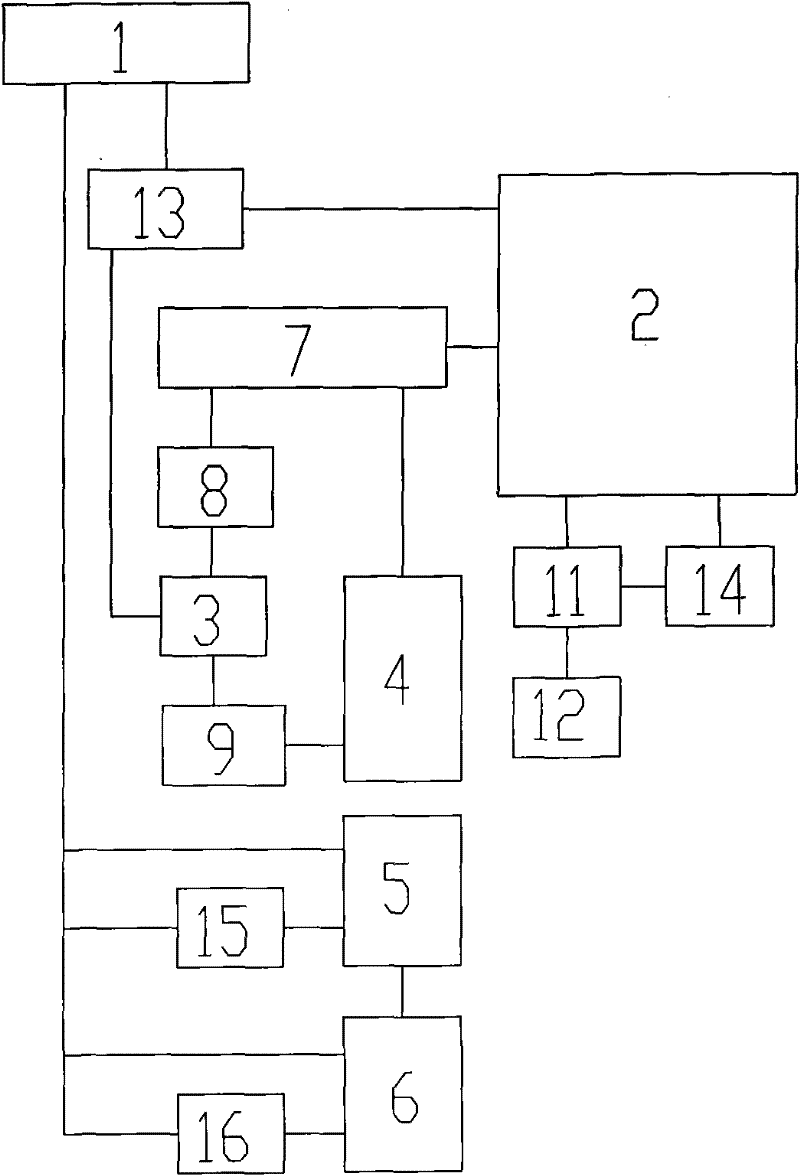

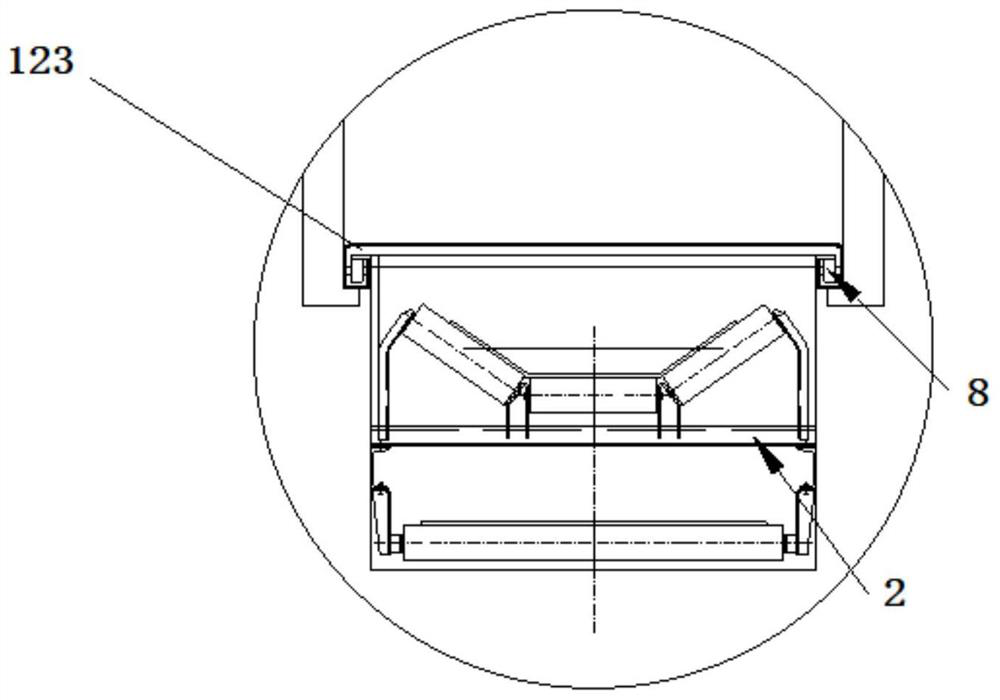

Continuous conveying system for statically metering materials

PendingCN112408003AContinuous unloadingPrecise unloadingConveyorsLoading/unloadingControl engineeringControl theory

The invention provides a continuous conveying system for statically metering materials. The continuous conveying system comprises a two-way conveying belt connected below the discharge end of an unloading conveying belt, a metering conveying unit A and a metering conveying unit B are correspondingly connected below the two ends of the two-way conveying belt, the metering conveying unit A and the metering conveying unit B each comprise a truss, weighing metering sensors are arranged between the trusses and racks, and the conveying belt is arranged on the trusses. According to the solution, in amaterial receiving process of the metering conveying unit B, the metering conveying unit A completes the metering weighing task and conveys the materials to the downstream, the conveying belt is vacated to wait for the next material receiving and weighing process, so that static accurate metering of the materials is completed, continuous work of the two-way conveying belt is guaranteed, and certainly, the continuous discharging process of the cabin materials is guaranteed.

Owner:JINLONG COPPER +2

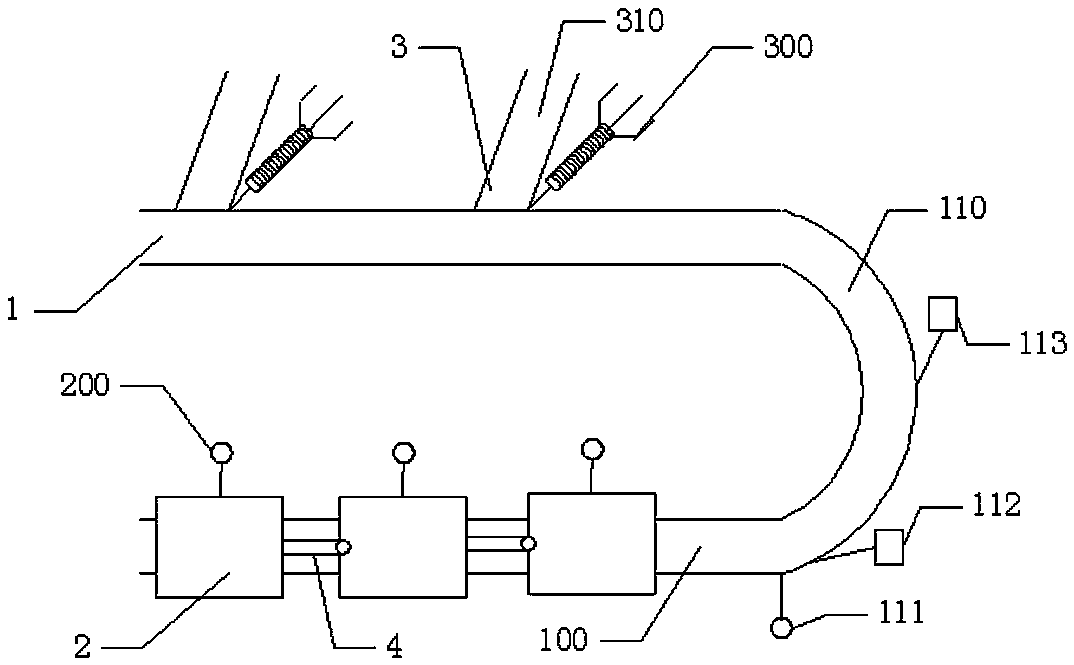

Express package conveyor

InactiveCN108313647APrecise unloadingImprove handlingControl devices for conveyorsMechanical conveyorsDistance sensorsMechanical engineering

The invention discloses an express package conveyor. The express package conveyor comprises a conveying rail, multiple conveying components and a motor driving device, wherein the conveying rail is provided with a first conveying rail and a second conveying rail; the first conveying rail comprises a first basal body and a first conveying belt; the first basal body is linearly arranged; the secondconveying rail comprises a second basal body and a second conveying belt; the second basal body is arranged in a curved manner; the first conveying belt and the second conveying belt are integrally molded; the multiple conveying components are operated on the conveying rail; the motor driving device drives the first conveying belt and the second conveying belt to operate on the first basal body and the second basal body; and the second basal body is provided with a distance sensor, a speed reducing component and an acceleration component. The speed of driving the conveying components to the curved rail is adjusted through the speed reducing component and the acceleration component to be the same with the speed of operating on the linear rail, so that packages are operated at precise consistent speed for precise unloading from the conveying components in a correct position.

Owner:尤联资

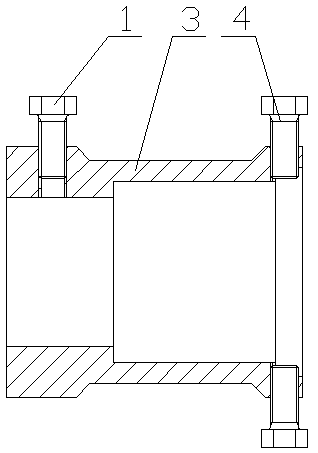

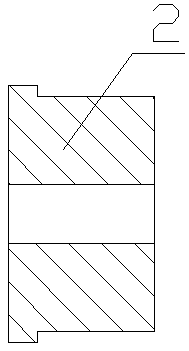

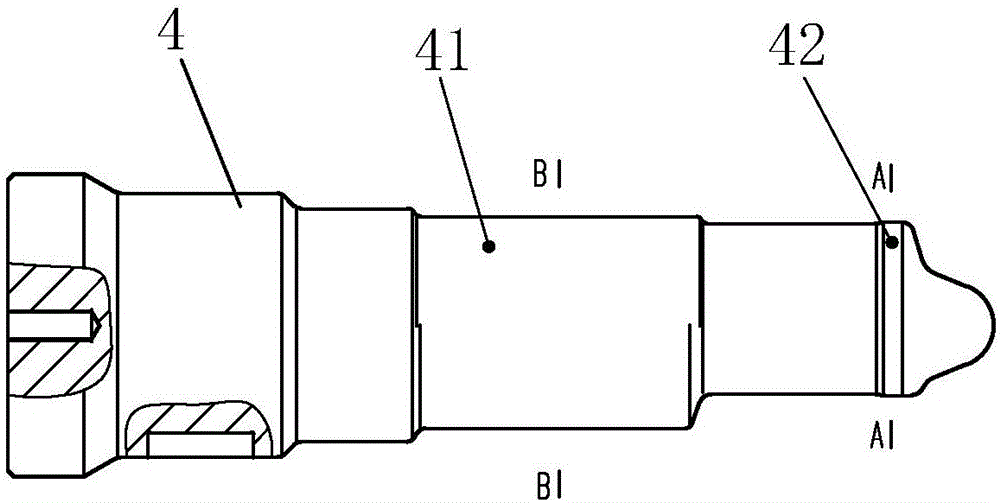

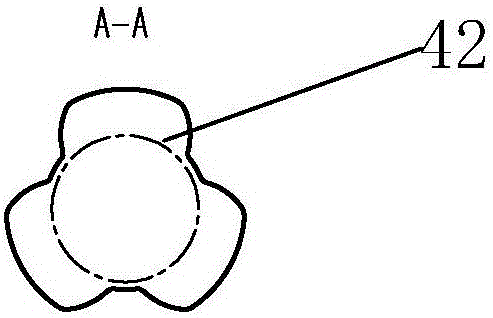

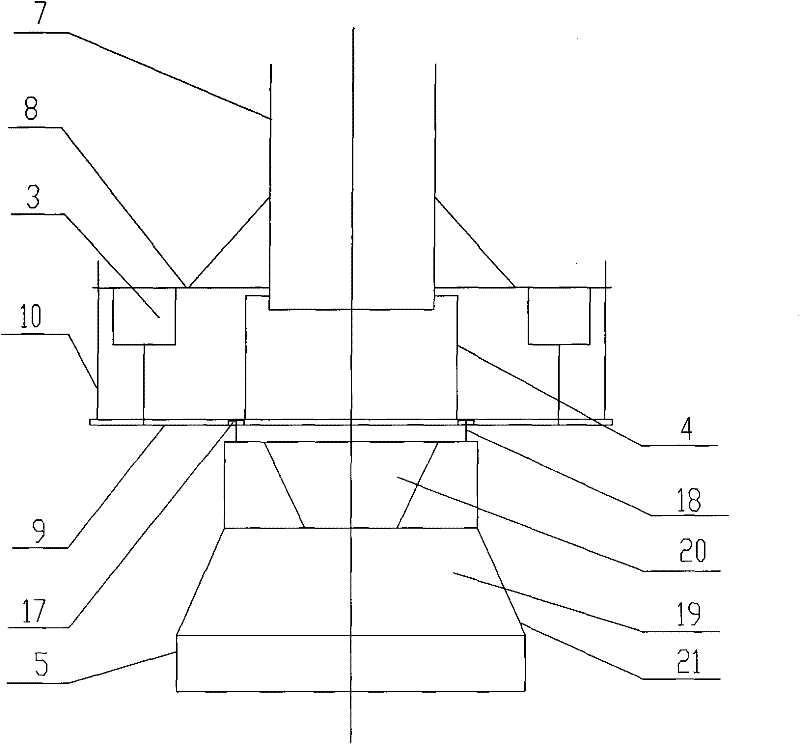

Cardan joint back-extruding guiding structure suitable for 2000T automatic mechanical press

InactiveCN107433292APrecise unloadingReduce manufacturing costExtrusion profiling toolsTriple effectMachine press

The invention discloses a cardan joint back-extruding guiding structure suitable for a 2000T automatic mechanical press. The cardan joint back-extruding guiding structure comprises an upper punch spraying cooling guiding device and a lower die spraying cooling guiding device; the upper punch spraying cooling guiding device comprises an upper die body and an unloading ring; the upper die body and the unloading ring are connected through a pulling rod; the upper die body is provided with a punching head; the punching head penetrates through the unloading ring and protrudes from the unloading ring; a plurality of penetrating first damping holes are formed in the unloading ring; the punching head comprises a guiding part and an extruding part; the lower die spraying cooling guiding device comprises a lower die body and a guiding sleeve which are connected; the guiding sleeve is positioned above the lower die body and is matched with the guiding part of the punching head; a penetrating second damping hole is formed in the guide sleeve; a cavity which is matched with the extruding part of the punching head is formed in the lower die body, and the upper part of the cavity is a guiding area which is matched with the guiding part; and the lower part of the cavity is an extruding area which is matched with the extruding part. The cardan joint back-extruding guiding structure can realize the triple effects of guiding, spraying and unloading.

Owner:江苏大洋精锻有限公司

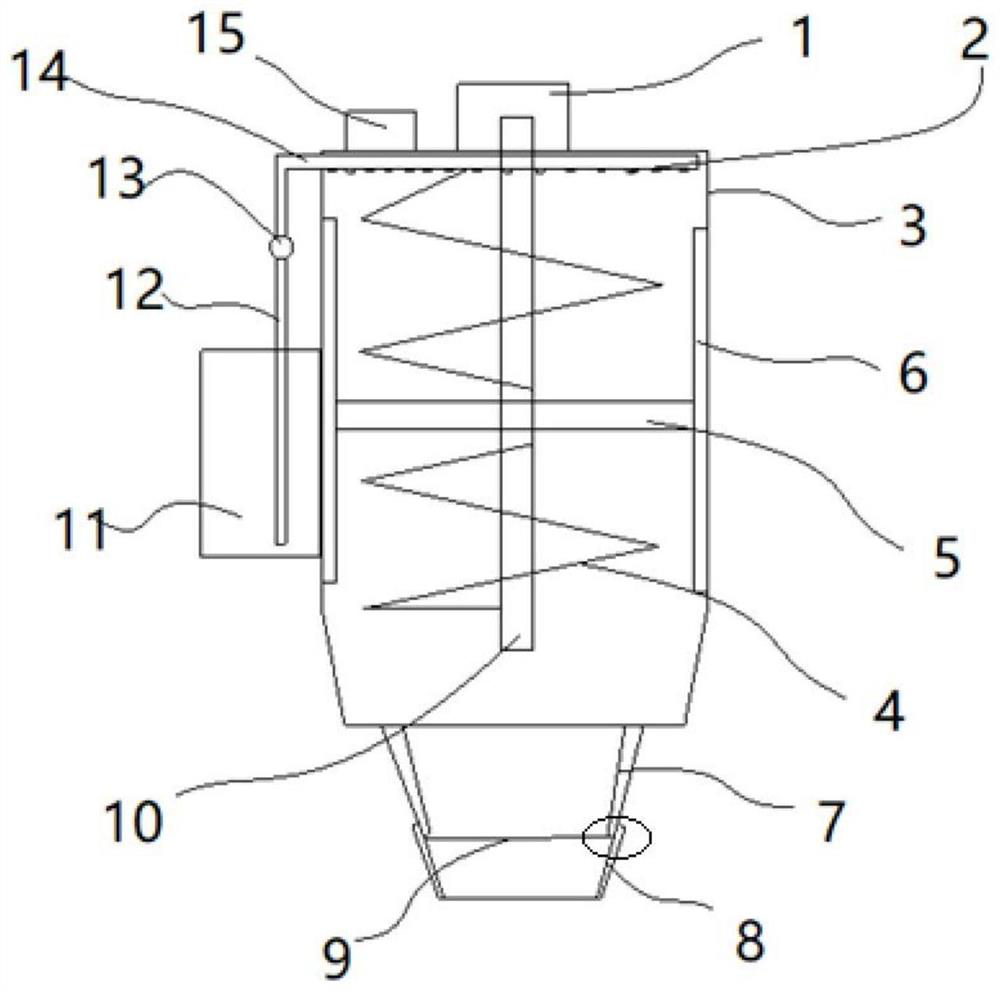

Super capacitor liquid injection method and liquid injection device

ActiveCN104008890ASimple structureReduce auxiliary timeHybrid/EDL manufactureActivated carbonDiaphragm pump

The invention relates to the field of capacitor manufacture, and aims to provide a super capacitor liquid injection method and a liquid injection device. The super capacitor liquid injection method comprises the following steps: (1) air in a super capacitor is pumped out for the first time to enable the vacuum degree to be lower than 1pa, and the state is kept for 5-20 minutes; (2) electrolyte accounting for 75-92% of the total liquid injection volume is pumped into a liquid storage tank by a diaphragm pump; (3) the electrolyte in the liquid storage tank is sucked into the super capacitor and soaked for 2-5 minutes to enable the electrolyte to fully fill activated carbon pores; (4) air in the super capacitor is pumped out for the second time to enable the vacuum degree to reach 10-30pa, and the state is kept for 1-5 minutes; (5) electrolyte accounting for 8-25% of the total liquid injection volume is pumped into the liquid storage tank; and (6) the electrolyte in the liquid storage tank is sucked into the super capacitor under negative pressure. By adopting the super capacitor liquid injection method, electrolyte is enabled to fully fill activated carbon pores, and liquid injection volume control is accurate.

Owner:NINGBO CRRC NEW ENERGY TECH CO LTD

Concrete mixer

PendingCN112776172APrecise unloadingReduce labor intensityMixing operation control apparatusCement mixing apparatusEngineeringStructural engineering

Owner:YULIN UNIV

Automobile part machining die automatic unloading device

InactiveCN110586790AReduce workloadPrecise unloadingShaping toolsMetal-working feeding devicesControl systemWorkload

The invention provides an automobile part machining die automatic unloading device. The automobile part machining die automatic unloading device comprises a mounting seat, a movable drive part, a control system, an unloading assembly and limiting parts. The left side of the mounting seat is connected to a lower die operating table. The unloading assembly driven by the movable drive part to move left and right back and forth is arranged on the right side of the mounting seat. The two sets of limiting parts are located on the left side and the right side of the unloading assembly separately. Thecontrol system is arranged on the mounting seat. Through the cooperation of the mounting seat, the movable drive part, the control system, the unloading assembly and the limiting parts, movement androtation paths of the unloading assembly are limited, precise unloading is achieved, the automation degree is high, the workload of workers is reduced, and the working efficiency is improved; and through the cooperation of an adsorption part and a dust removal part, cooling, dust removing and unloading are completed simultaneously, the functions are diverse, and high practicality is achieved.

Owner:上海翼欣汽车技术中心

Two-degree-of-freedom sealed discharging device

InactiveCN110525942AReduce pollutionRealize continuous unloadingConveyorsLoading/unloadingTruckTwo degrees of freedom

The invention provides a two-degree-of-freedom sealed discharging device. The two-degree-of-freedom sealed discharging device comprises a first conveying belt and a second conveying belt. A conveyingbelt dust cover is located on the outer side of the first conveying belt and the outer side of the second conveying belt and fixedly connected with the first conveying belt and the second conveying belt. A driving mechanism is used for driving the conveying belt dust cover to move forwards and backwards along a preset path; and a lifting mechanism is used for driving the second conveying belt to move up and down around a first hinge in the vertical direction. The unloading point of an unloading belt conveyor is adjusted in the horizontal direction and the vertical direction according to the position of a truck or the unloading point, and therefore flying dust pollution caused in the loading and unloading process can be greatly reduced.

Owner:世邦工业科技集团股份有限公司

Dedusting equipment and method for fixed-point unloading movable dumper

ActiveCN102085966BImprove working environmentRealize automatic controlLoading/unloadingAutomatic controlDrive wheel

The invention relates to the technical field of unloading and dedusting bulk materials, in particular to dedusting equipment and a dedusting method for a fixed-point unloading movable dumper. The equipment comprises a central control room movable dumper, a feeding groove, a storage bin, a hanger plate, an electromagnet, a lower seat, a guide rod and a telescopic dustproof cover, wherein an automatic control system, a dumper encoder, two frequency conversion driving devices, two driving wheels with reverse taper directions, a feeding groove encoder, a level gage, a dustproof cover on the upper side of the feeding groove, an outer barrel in an inverted funnel shape, an inner barrel in a funnel shape, and rigid sealing strips are arranged in the movable dumper. The dedusting method comprises the following steps that: a central control room operates the movable dumper to move, align, stop, unload and move away through the automatic control system on the movable dumper according to information transmitted by the level gage in each storage bin. Through the invention, energy is saved and emission is reduced when the movable dumper unloads materials, automatic control is convenient to realize, the working efficiency of the equipment is improved, the working environment of a worker is improved, and investment is saved.

Owner:ANSTEEL GRP MINING CO LTD

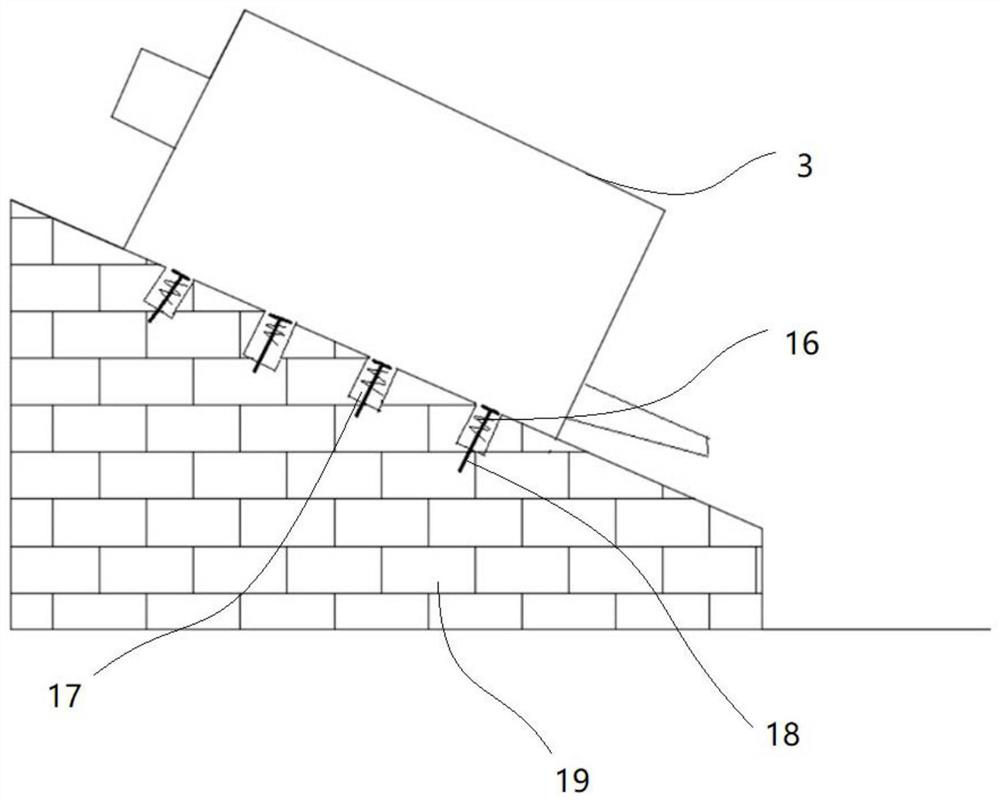

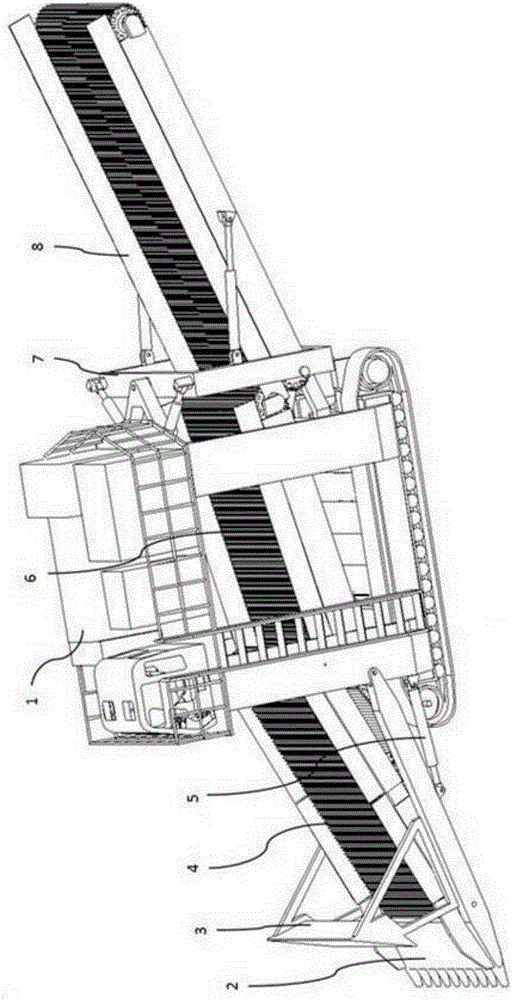

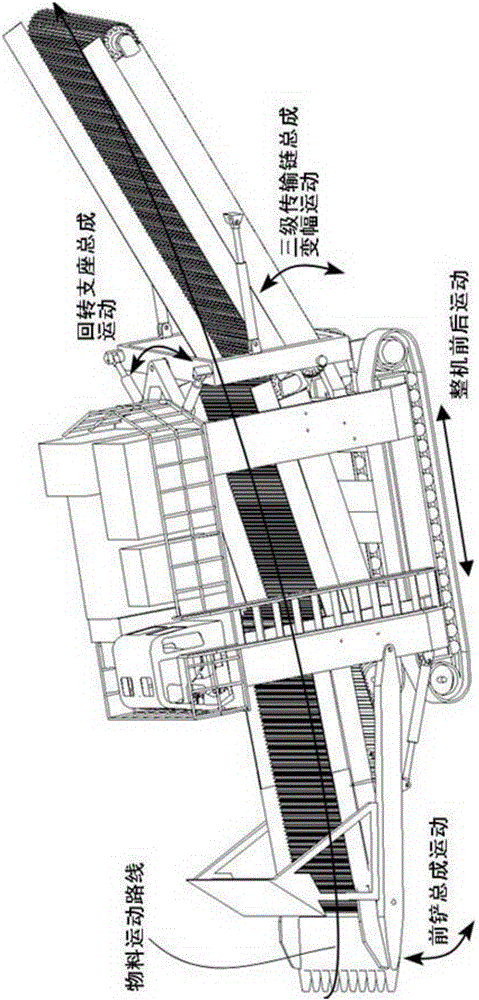

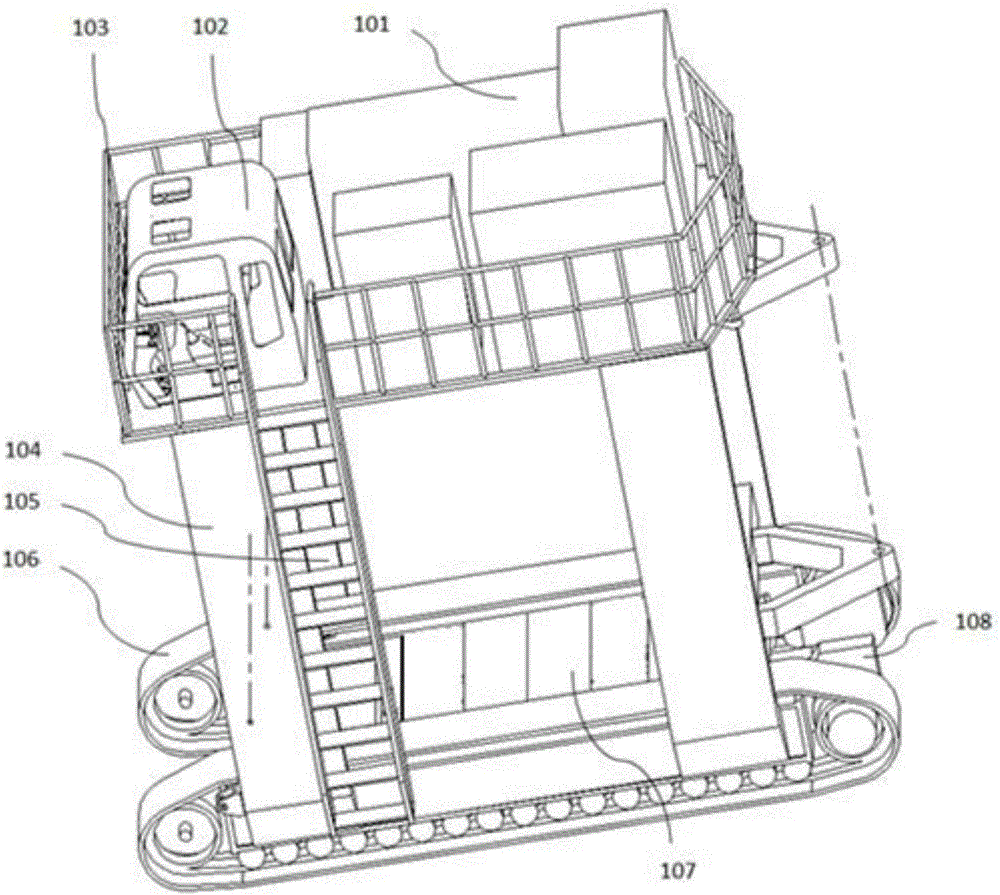

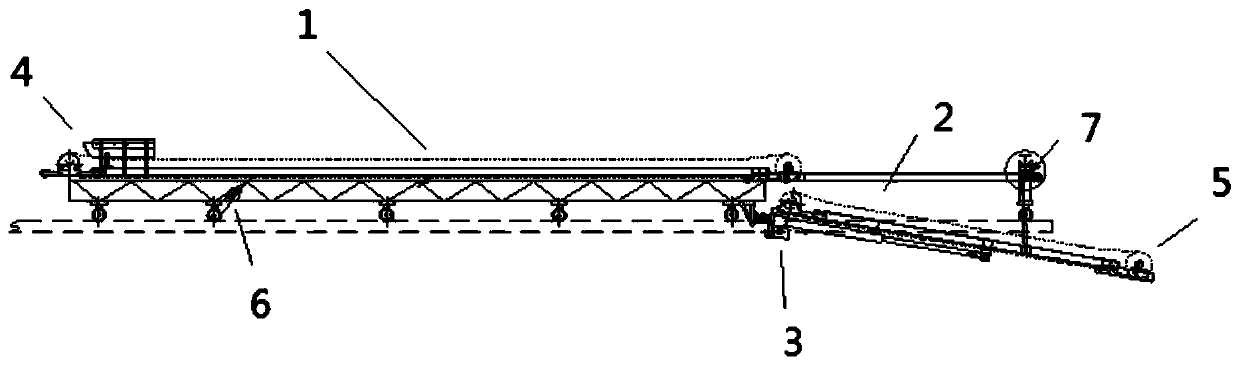

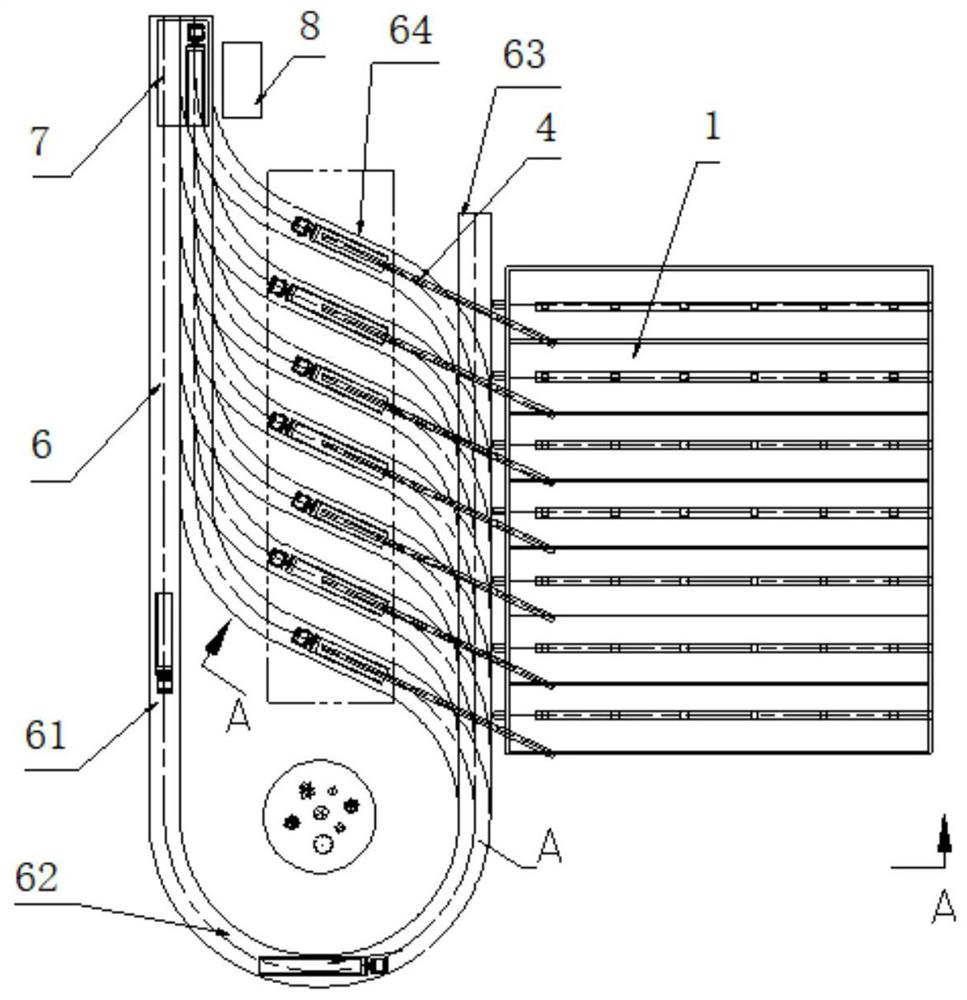

Continuous loading type ore loading machine for open-pit quarry

ActiveCN106697975AEnables continuous loading operationsPrecise unloadingOpen-pit miningLoading/unloadingEngineeringShovel

The invention relates to an ore loading machine. In order to solve the problem that the ore loading machine is incapable of realizing loading operation, the invention provides an ore loading machine. The ore loading machine comprises a walkable host machine, as well as a primary transmission chain assembly, a secondary transmission chain assembly and a tertiary transmission chain assembly which are sequentially connected to the host machine from front to back, wherein the front end of the host machine is provided with a front shovel assembly; the front shovel assembly comprises a front shovel rack and a front shovel oil cylinder, the rear end of the front shovel rack is articulated with the host machine; the front end of the front shovel rack is provided with a front shovel; two ends of the front shovel oil cylinder are respectively articulated with the front shovel rack and the host machine; the front end of the primary transmission chain assembly is connected with the front shovel rack, and the front end of a transmission chain of the primary transmission chain assembly is positioned at the rear side of the front shovel. By virtue of traction force generated by the ore loading machine, the front shovel assembly is inserted into a material pile; and further by virtue of up-and-down movement of the front shovel, the repose angle of ore rocks in the material pile is destroyed, so that the ore rocks cave onto the primary transmission chain. By virtue of continuous movement of the primary transmission chain, the second transmission chain and the tertiary transmission chain, the ore rocks are conveyed to a tramcar until the tramcar is full of ore rocks.

Owner:柳工(常州)矿山机械有限公司

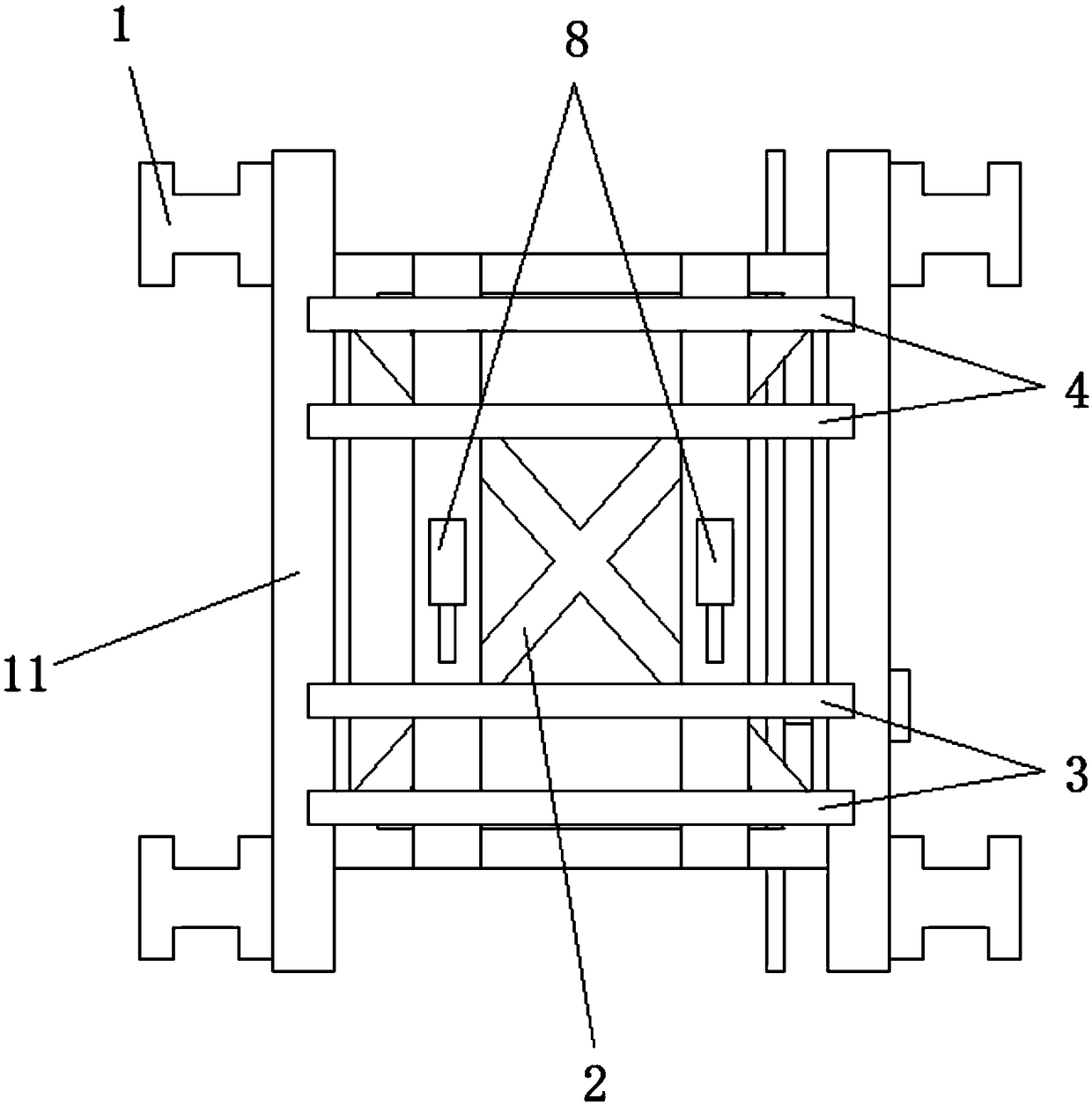

Concrete transporting machine transfer avoidance device

PendingCN109292388AIncrease productivityEasy to slideMechanical conveyorsProduction lineElectric machinery

The invention relates to a concrete transporting machine transfer avoidance device. The concrete transporting machine transfer avoidance device comprises a supporting frame, a beam frame, front guiderails, rear guide rails, a driving rack, a driving gear and a driving motor. The front guide rails and the rear guide rails are arranged in parallel and fixedly connected to the beam frame. The beam frame is arranged on the supporting frame in a sliding mode. The driving rack is fixedly connected to the beam frame and extends in the sliding direction of the beam frame. The driving motor is fixedlyconnected to the supporting frame, and an output shaft of the driving motor is connected with the driving gear in a transmission mode. The driving gear and the driving rack are matched in a transmission mode. According to the concrete transporting machine transfer avoidance device, due to the switching of the front guide rails and the rear guide rails, the purpose that a plurality of concrete transporting machines transport materials among a plurality of material distribution pouring production lines can be achieved, and the production efficiency is effectively improved.

Owner:常州砼筑建筑科技有限公司 +1

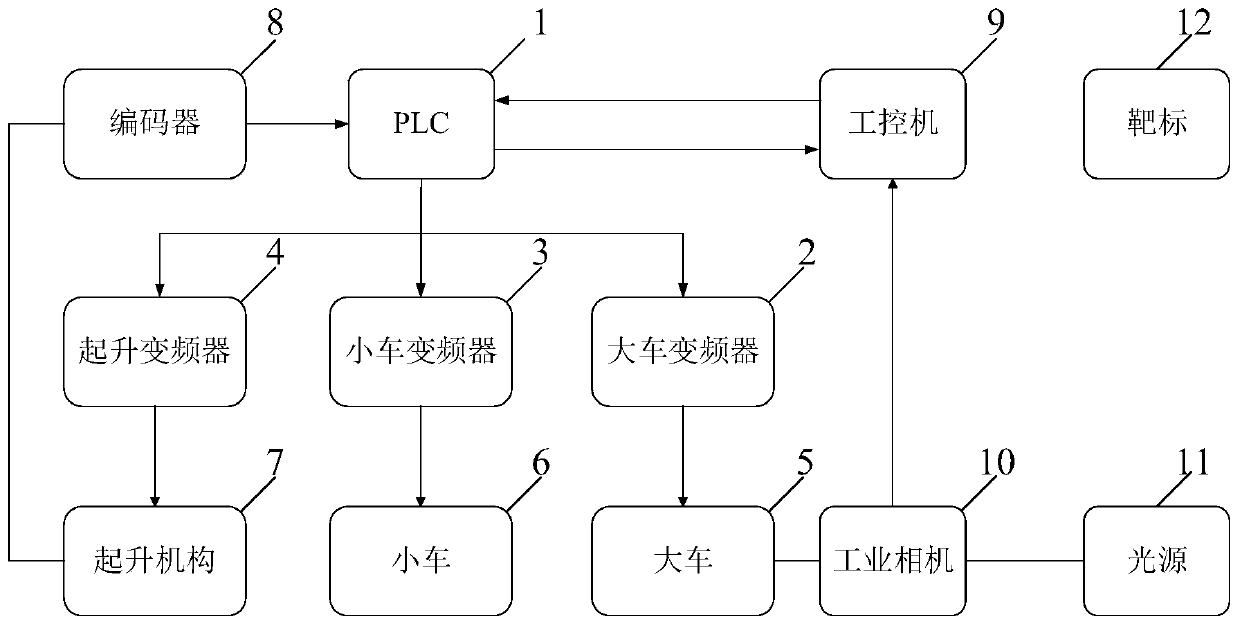

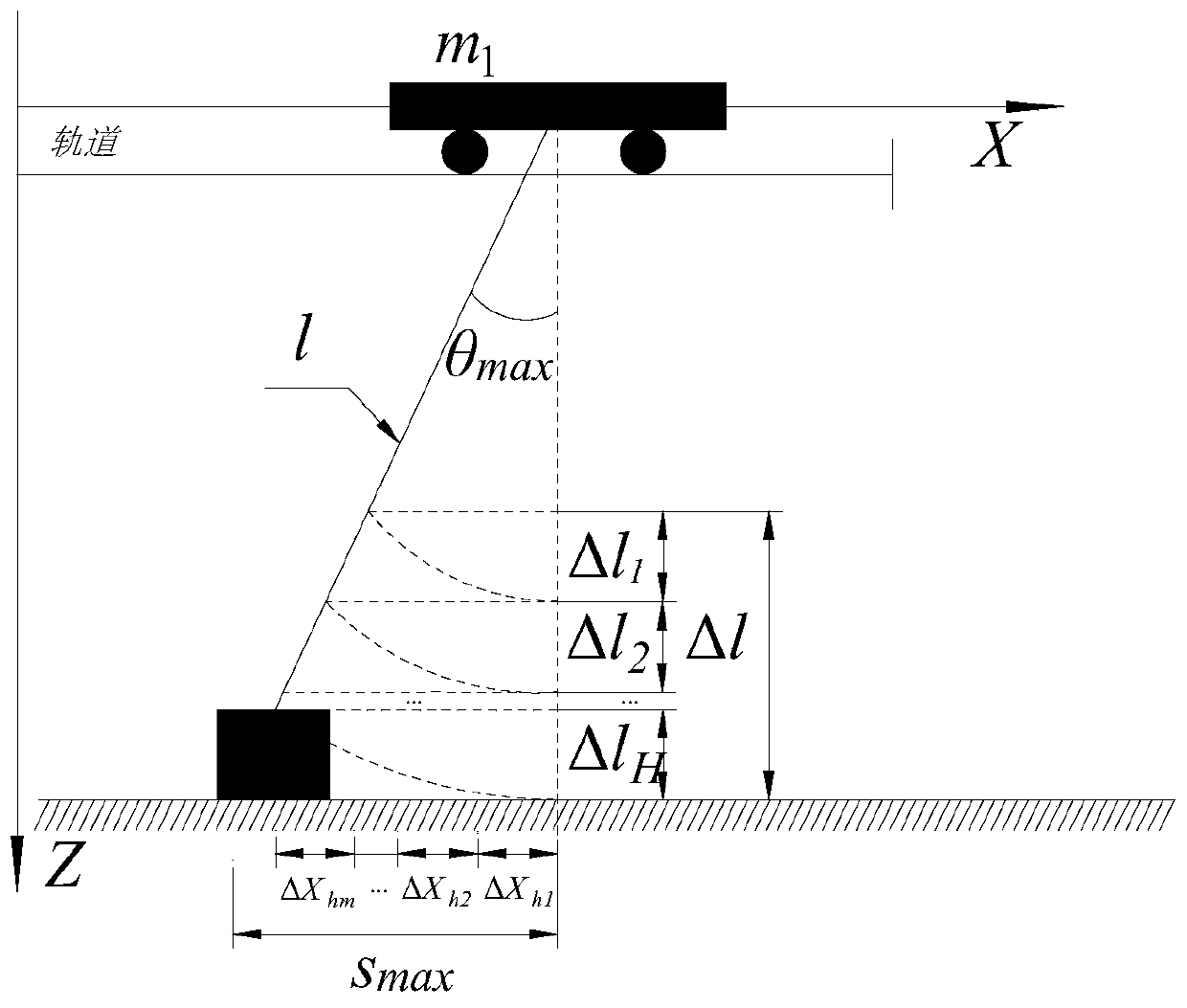

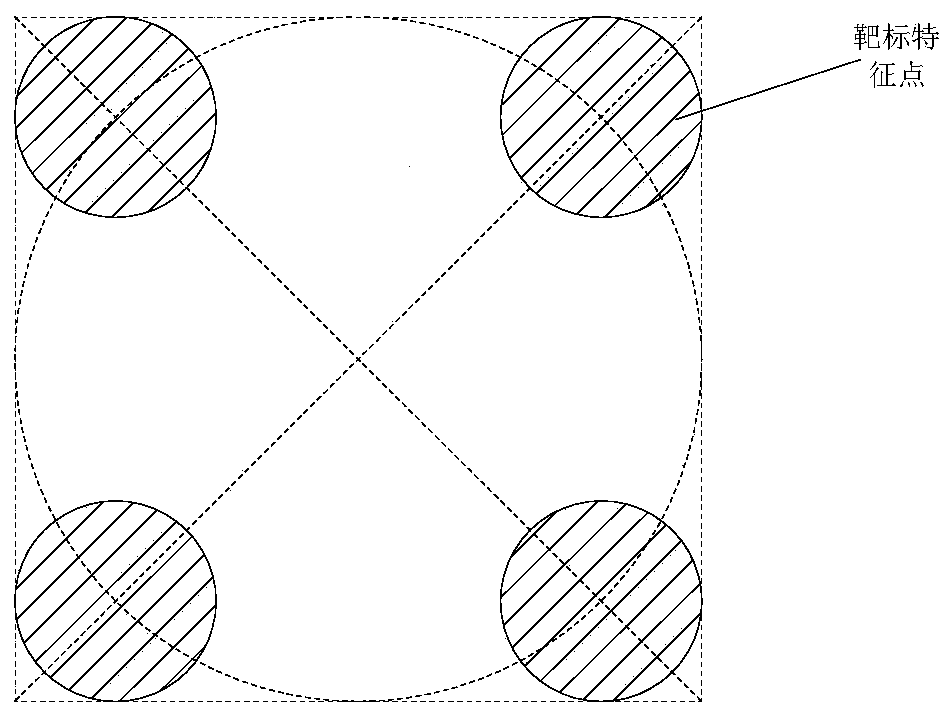

Multi-height calibration measurement method and crane anti-slanting and precise positioning method

InactiveCN108675142BRealize anti-cable pull controlPrecise unloadingGeometric CADOptical rangefindersMachine visionMathematical model

The invention discloses a multi-height calibration measurement method based on a monocular camera, and a crane anti-slanting and precise positioning method, wherein the target position is precisely measured by a monocular camera in the case of different heights through multi-height calibration based on a machine vision technology. According to the multi-height calibration measurement method, the depth-of-field range of a camera is divided into multiple segments, the camera visual field within each height range segment is equally divided into multiple segments in a horizontal direction and a vertical direction, and the target respectively performs horizontal moving and vertical moving multiple times within each segment of the depth-of-field change range during the camera calibration, such that the mathematical model of the pixel distance and the actual distance at different heights is established. According to the present invention, the method has advantages of high sensitivity, convenient implementation and strong robustness, and can greatly improve the operation safety and work efficiency of cranes and promote the automated, digitized and intelligent development of cranes.

Owner:WUHAN UNIV OF TECH

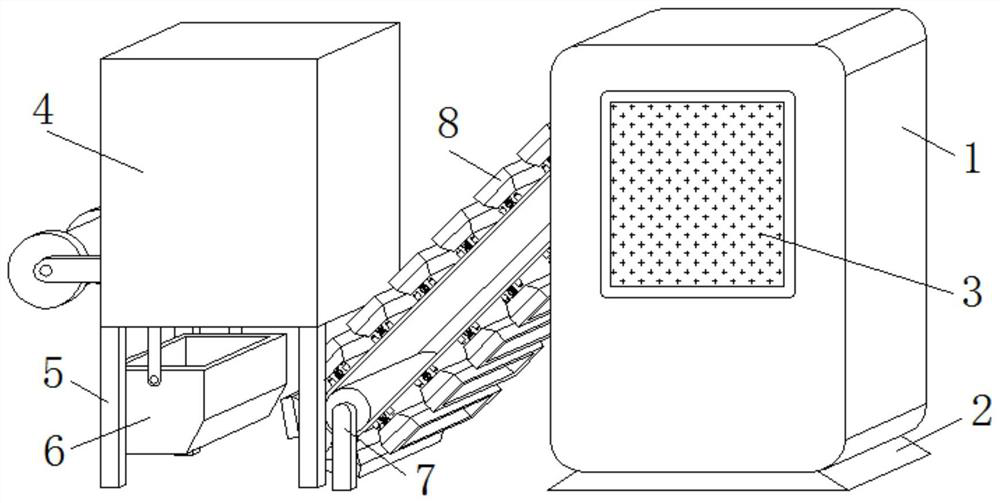

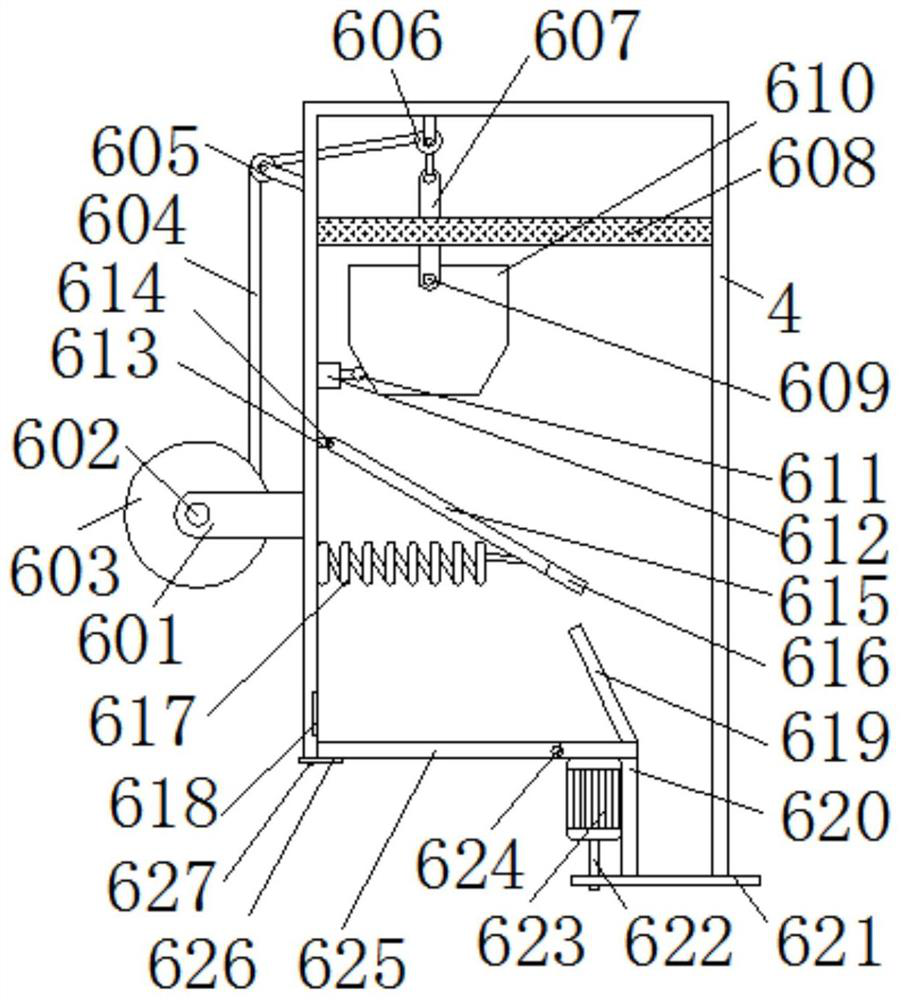

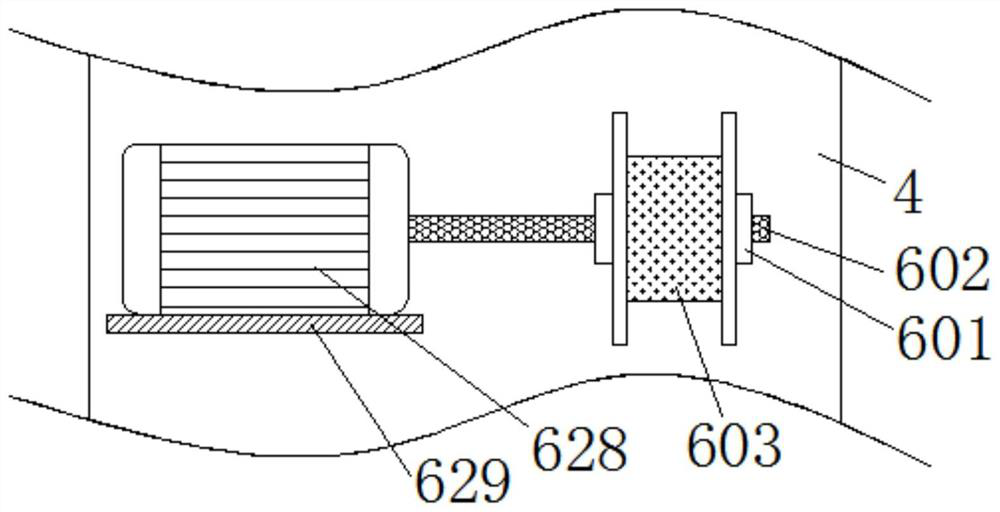

Charging mechanism of vanadium-nitrogen alloy processing equipment

The invention discloses a charging mechanism of vanadium-nitrogen alloy machining equipment. The charging mechanism comprises a machining equipment body, and a base is fixedly installed at the bottom end of the machining equipment body; and an observation window is connected with the front end face of the machining equipment body, and a storage bin is installed on the outer side of the machining equipment body. In the charging mechanism, under the action of a uniform feeding mechanism, materials are added into a material conveying box, and under the power of a servo motor, a winding drum is driven by a rotating rod to wind a connecting rope, so that the material conveying box is driven by the connecting rope to move upwards through a vertical rod; through power-on of an electric push rod, the material conveying box is pushed through an abutting block on one side of the material conveying box; under the effect that the vertical rod is limited in a fixing plate, the material conveying box is rotated through a movable shaft, and therefore the material conveying box discharges materials in the storage bin; thus, vanadium-nitrogen alloy enters a discharging port through a first material guide plate and a second material guide plate; through such arrangement, a user can add the materials to the processing equipment at the bottom.

Owner:JIUJIANG FANYU NEW MATERIALS

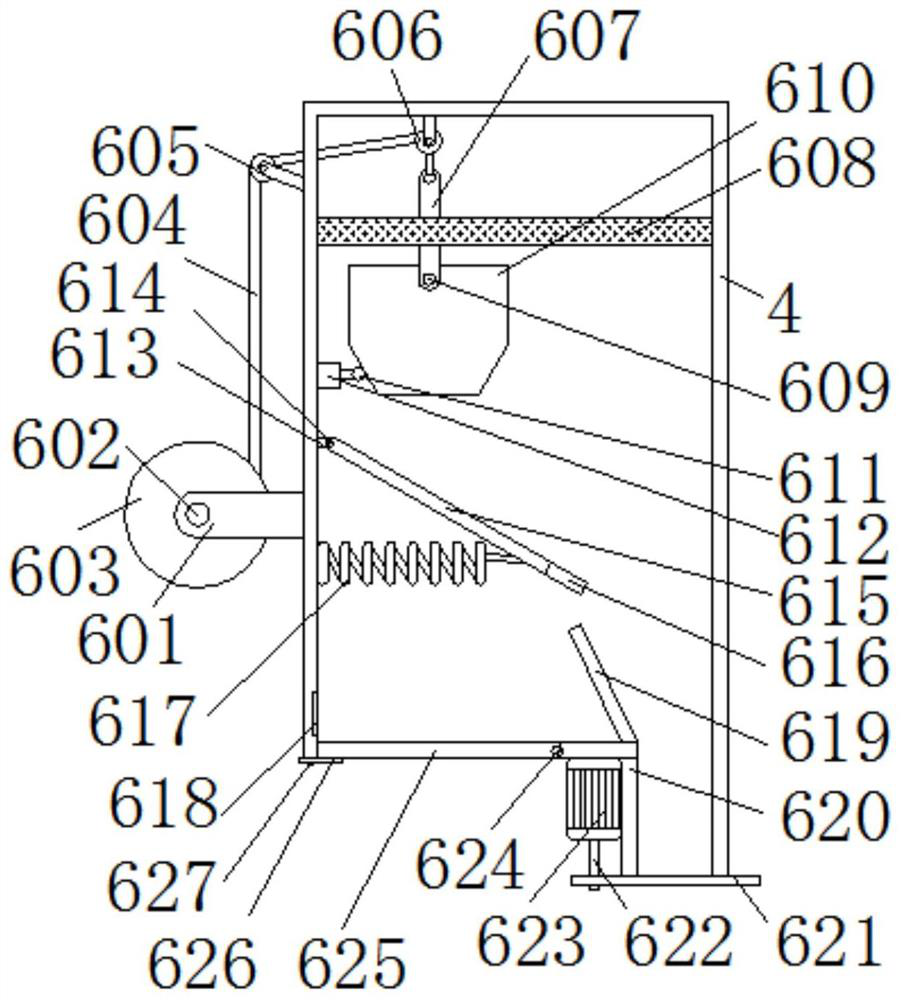

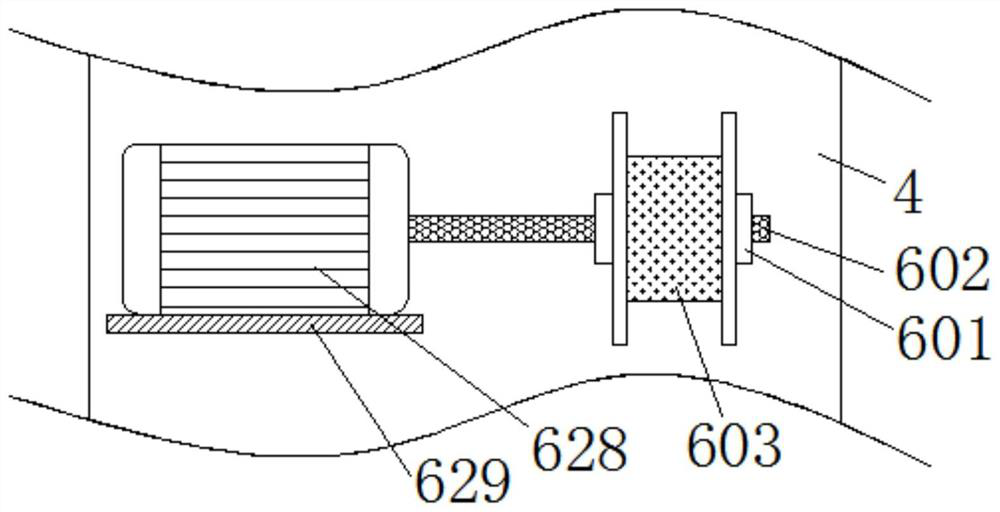

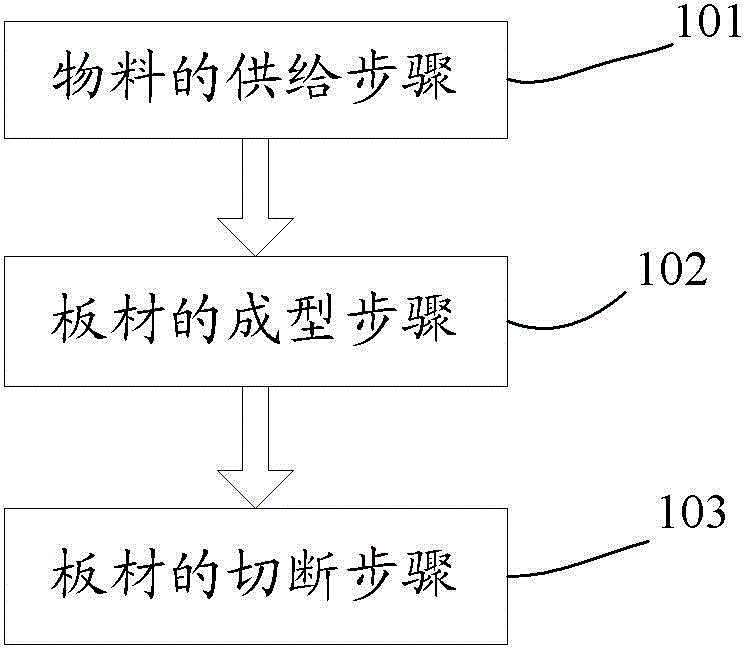

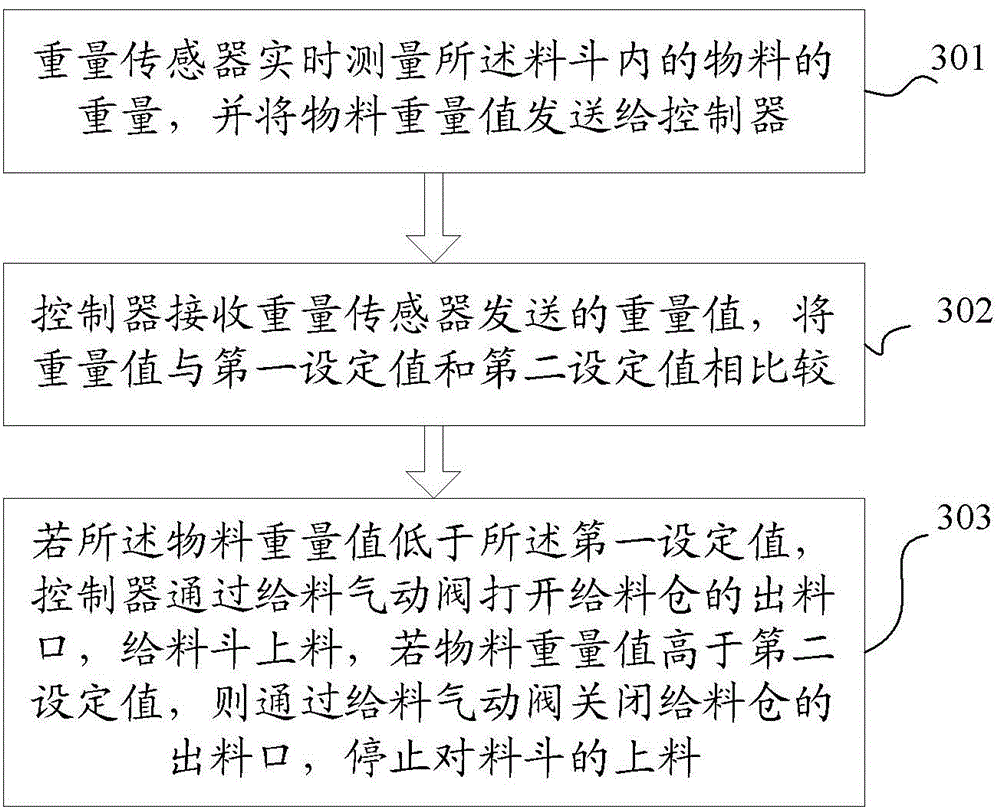

High-speed producing and controlling method for plaster plates

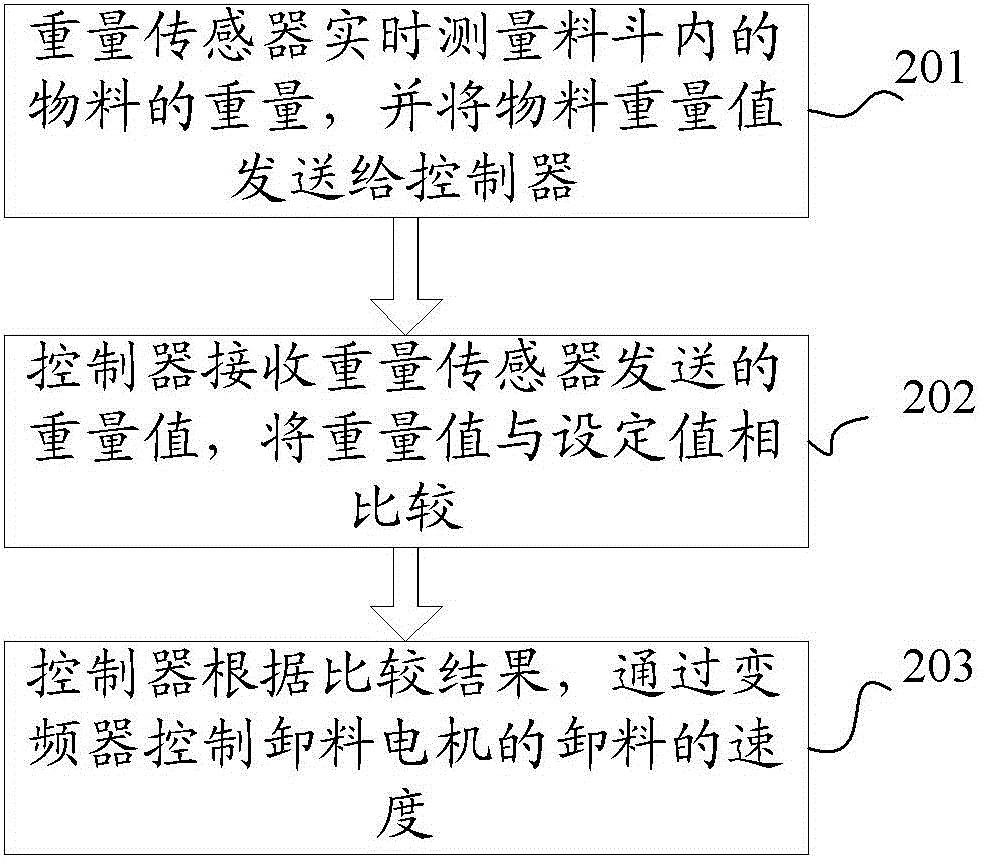

ActiveCN102873745BPrecise feedingPrecise unloadingFeeding arrangmentsProduction lineForming processes

The invention discloses a high-speed producing and controlling method for plaster plates. The high-speed producing and controlling method comprises a feeding and discharging step, a forming step and a plate cutting-off step. The feeding and discharging step comprises the following substeps of: monitoring the weight of materials in a hopper in real time; comparing a monitored result with a set value; controlling discharging speed according to a comparison result; comparing the monitored result with a first set value and a second set value; and beginning to feed materials to the hopper from a feed bin or stopping feeding the materials to the hopper from the feed bin according to the comparison result. The forming step comprises a plate defect monitoring step. The plate defect monitoring step comprises the following substeps of: monitoring defects of plate products in a plate forming process in real time; comparing a monitored result with a preset controlling index; and adjusting production programs according to a comparison result. The plate cutting-off step comprises the following substep of: controlling a dual-servo motor to respectively drive an upper cutter and a lower cutter to simultaneously cut off plates on a production line according to the conveying speed of the plates on the production line. The high-speed producing and controlling method can meet requirements on large-scale and high-speed production of the plaster plates.

Owner:BEIJING NEW BUILDING MATERIALS PLC

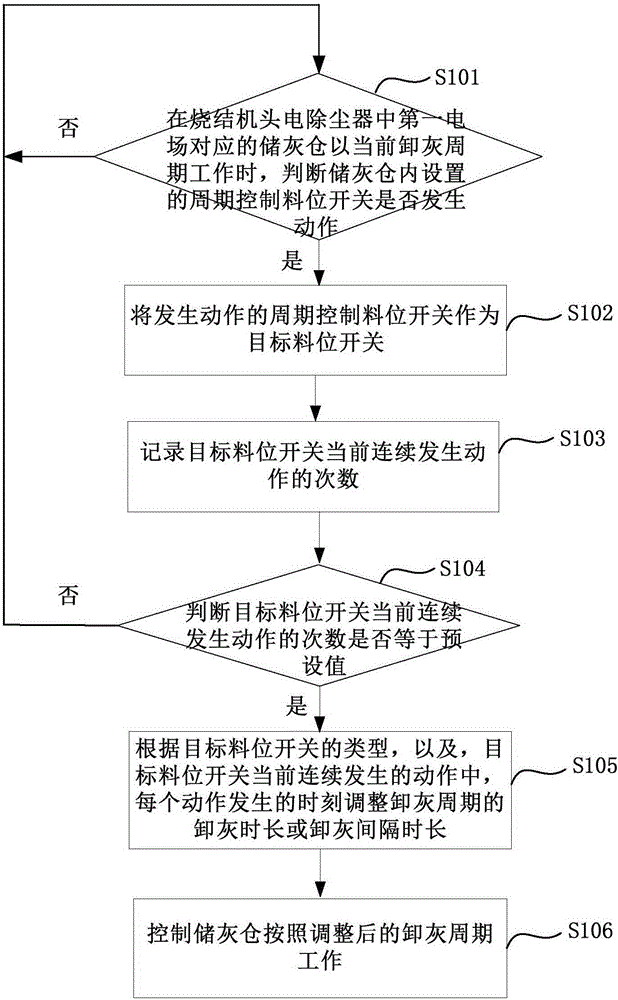

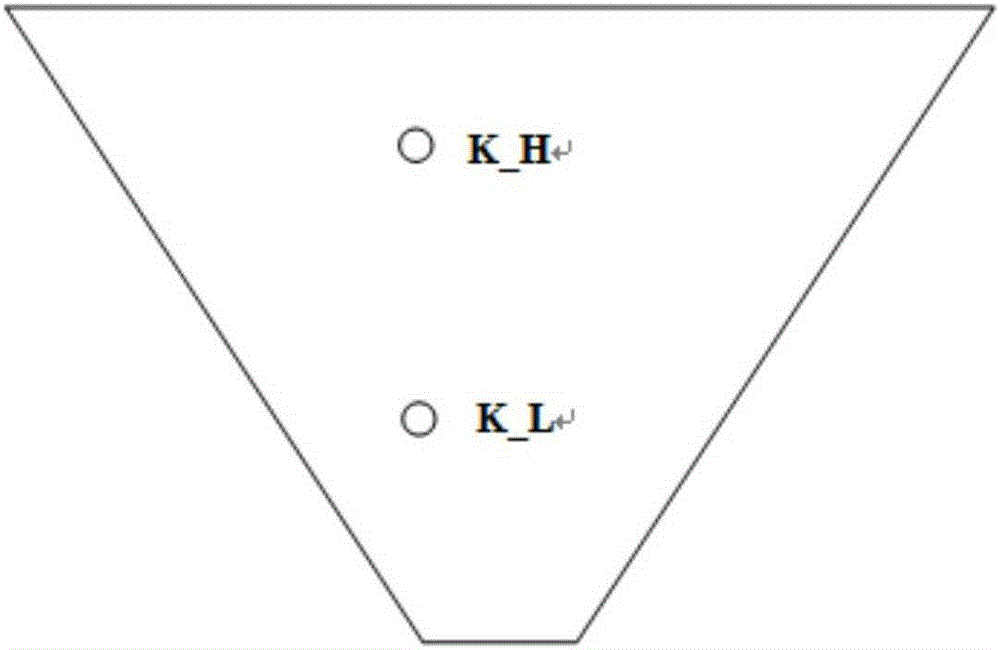

Dust unloading control method and device for electric dust remover of sintering machine head

ActiveCN105170334APrecise unloadingGuaranteed healthy operationElectrostatic separation detailsEngineeringMechanical engineering

The embodiment of the invention discloses a dust unloading control method and device for an electric dust remover of a sintering machine head. Through analysis of actions of a material level switch in a dust storage bin in the electric dust remover of the sintering machine head, the working dust unloading period of the dust storage bin is automatically adjusted, the dust unloading period of the dust storage bin can automatically adapt to the change of the dust removal amount of the electric dust remover of the sintering machine head in the sintering production process, and therefore accurate dust unloading, adapting to the production change, of the electric dust remover of the sintering machine head is achieved, and healthy and stable operation of the electric dust remover of the sintering machine head is guaranteed. Existing system hardware of the electric dust remover of the sintering machine head does not need to be changed, and accurate dust unloading can be achieved with low cost. Meanwhile, after the dust unloading period of the dust storage bin of the electric dust remover of the sintering machine head automatically adapts to sintering production, the material level switch in the dust storage bin cannot participate in or less participate in dust unloading control, the loss opportunity of the material level switch is effectively reduced, and the service life of the material level switch is greatly prolonged.

Owner:ZHONGYE-CHANGTIAN INT ENG CO LTD

A charging mechanism for vanadium nitrogen alloy processing equipment

The invention discloses a loading mechanism of vanadium nitrogen alloy processing equipment, which comprises a processing equipment body, a base is fixedly installed at the bottom end of the processing equipment body, and an observation window is connected to the front end of the processing equipment body. A storage bin is installed on the outside of the body. In the present invention, under the action of the uniform material injection mechanism, by adding material to the inside of the transport box, and under the action of energizing the servo motor, the rotating rod drives the winding drum to wind up the connecting rope, thereby giving the user The connecting rope drives the material box to move upward through the vertical rod, and the electric push rod is energized to make the block push the material box on one side of the material box. Under the action of the vertical rod being limited inside the fixed plate, the The transport box is rotated by the movable shaft, so that the transport box is discharged inside the storage bin, so that the vanadium-nitrogen alloy enters the discharge port through the first material guide plate and the second material guide plate. Through such an arrangement, This allows the user to add material to the processing equipment at the bottom.

Owner:JIUJIANG FANYU NEW MATERIALS

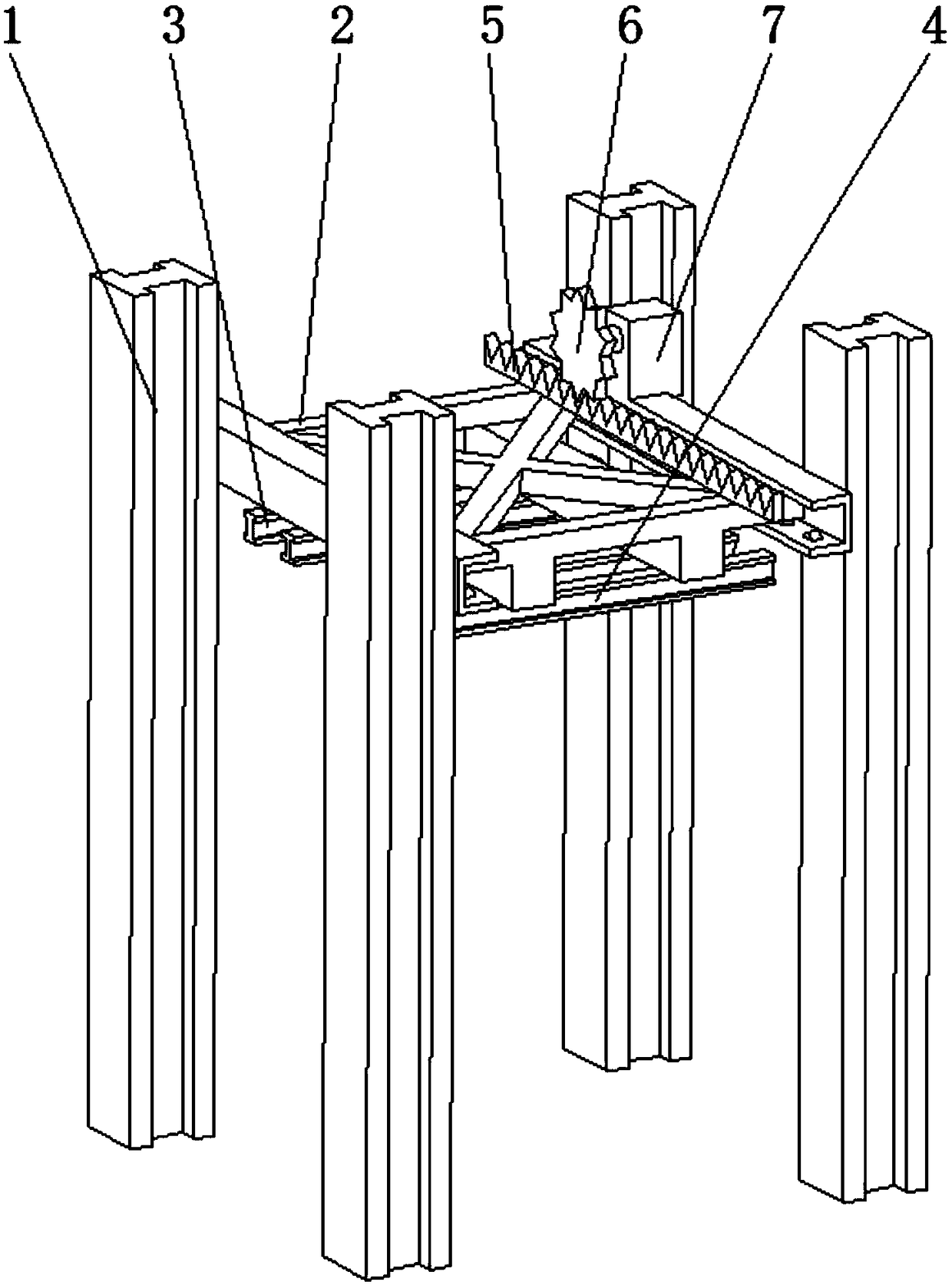

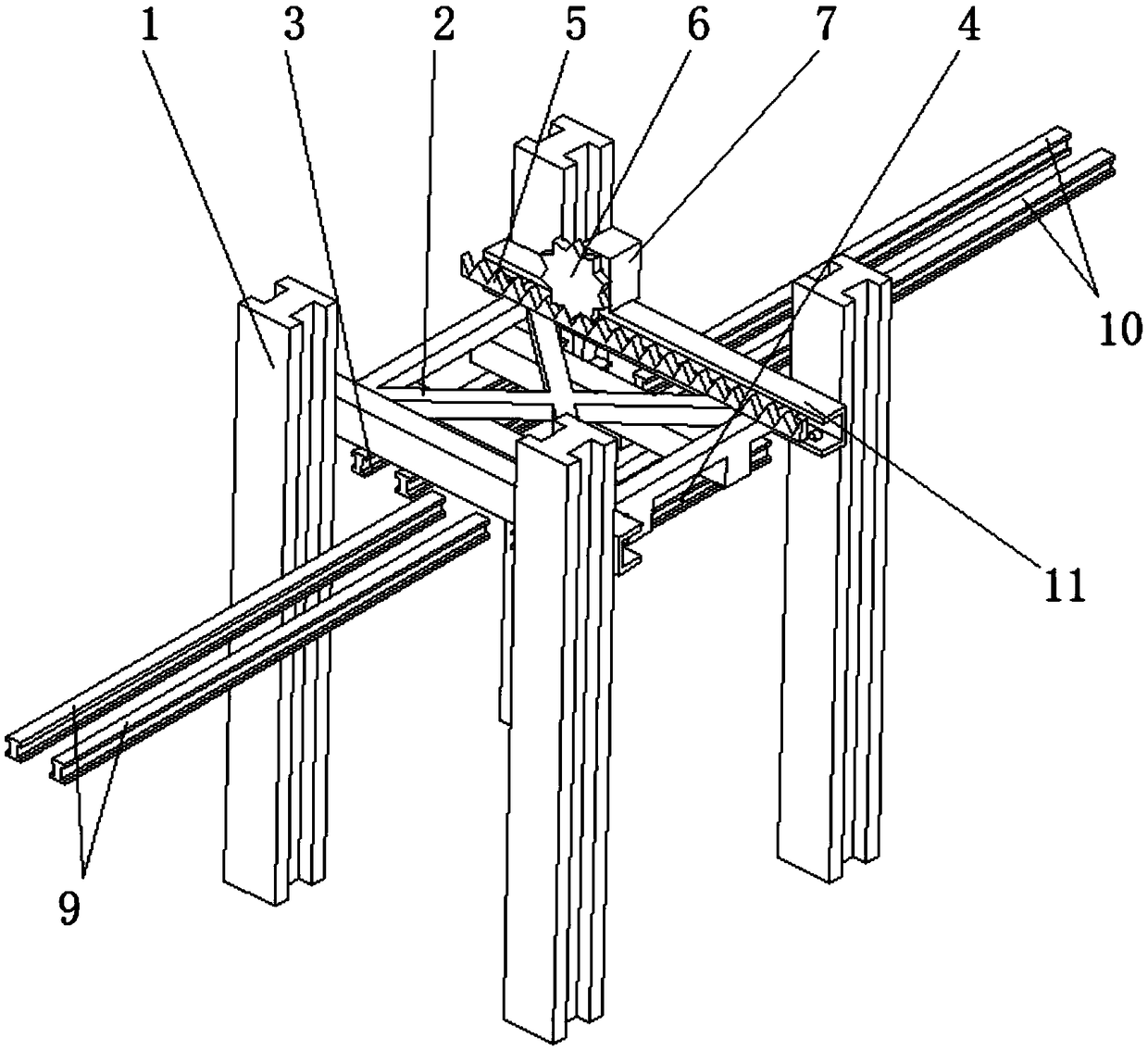

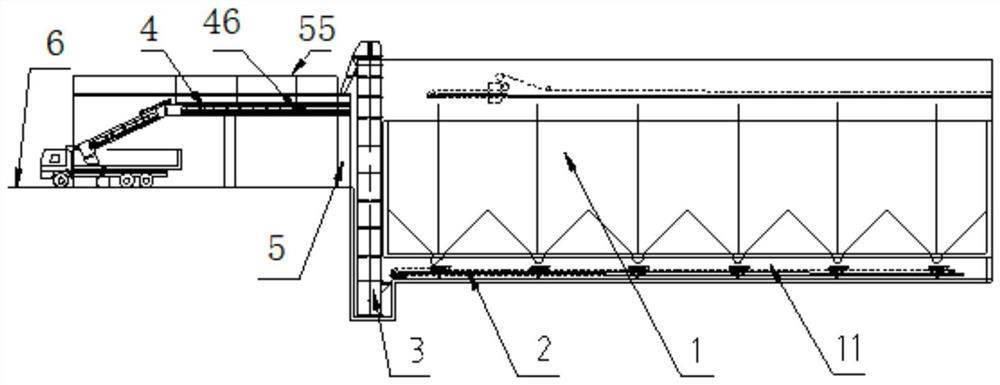

Three-dimensional printing type loading system and unloading method

ActiveCN110525943AHigh degree of automationPrecise unloadingConveyorsLoading/unloadingUniversal jointThree degrees of freedom

The invention provides a three-dimensional printing type loading system. The three-dimensional printing type loading system comprises a three-degree-of-freedom unloading device and a central control device; the three-degree-of-freedom unloading device comprises a first conveying belt and a second conveying belt, and the second end of the first conveying belt is connected with the first end of thesecond conveying belt through a first universal joint; the central control device is connected with the three-degree-of-freedom unloading device; according to a target discharging position, the central control device controls the first conveying belt of the three-degree-of-freedom unloading device to move front and back along a preset path, controls the second conveying belt to move up and down inthe vertical direction around the first universal joint, and / or controls the second conveying belt to rotate and swing left and right around the first universal joint, so a discharging opening is moved to the target discharging position for discharging materials. Continuous and accurate discharging in different directions can be achieved, the automation degree is high, time waste caused by movement of a truck is avoided, and the loading and unloading efficiency is obviously improved.

Owner:世邦工业科技集团股份有限公司

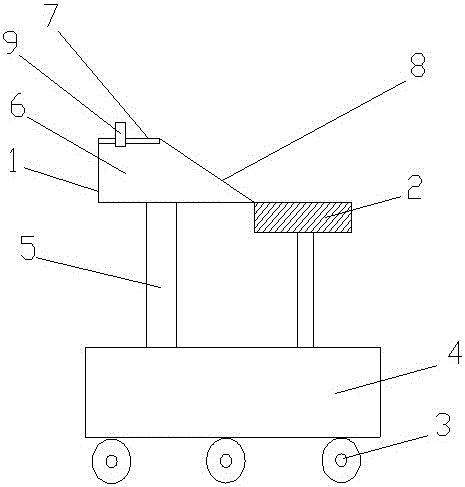

Unloading mechanism special for robot

InactiveCN106393173AHigh degree of automationWith height adjustment functionManipulatorInductorRobot machining

The invention discloses an unloading mechanism special for a robot. The unloading mechanism comprises an unloader and a conveyor, a movement mechanism is installed at the bottom of the unloader, a fixing base is installed at the upper end of the movement mechanism and provided with a lifting mechanism, an unloaded material conveying table is installed at the upper end of the lifting mechanism, a horizontal table face is arranged at the front end of the unloaded material conveying table, a slope face is arranged at the back end of the unloaded material conveying table, and the horizontal table face is jointed with the slope face; sliding mechanical pulling hands are installed on the two sides of the horizontal table face, the unloader is arranged at the lower end of the robot, and a machined piece unloading infrared inductor is arranged on the horizontal table face; and the conveyor is installed at the tail end of the slope face. By means of the above manner, the unloading mechanism can be special for robot machining unloading, the unloading device automation degree is high, arms of the robot can be accurately positioned for unloading, the unloader has the height adjusting function, and better unloading can be achieved through workpieces.

Owner:WUXI MINGJI INTELLIGENT MACHINERY CO LTD

Unmanned automated hook coupling device

ActiveUS11325704B2Easy to trackPrecise unloadingAircraft componentsUnmanned aerial vehiclesCouplingMonitoring system

Owner:VESSEL AEROSPACE CO LTD

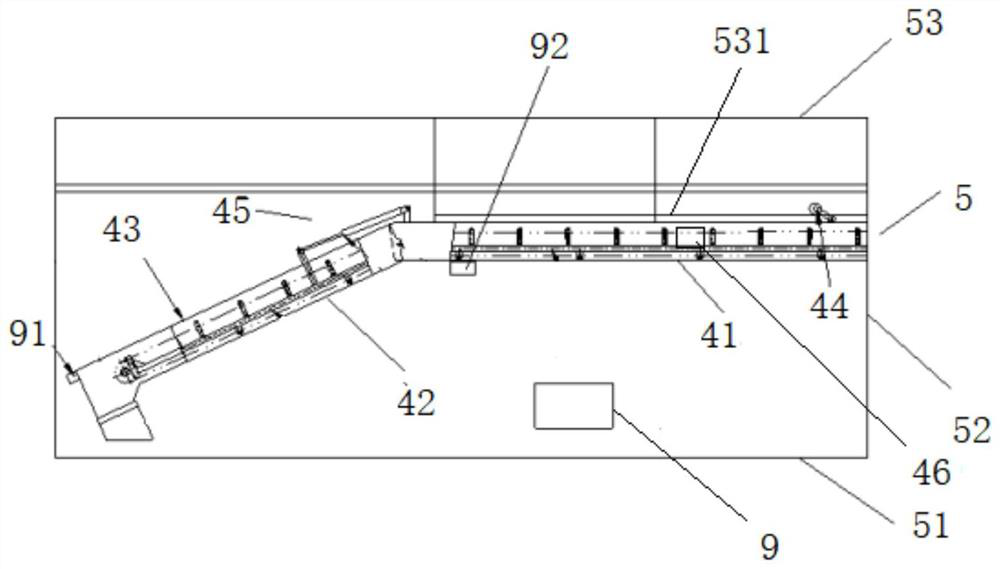

A two-dimensional printing loading system and unloading method

ActiveCN110884867BReduce pollutionImprove loading and unloading efficiencyConveyorsLoading/unloadingTransmission beltControl theory

The present invention provides a two-dimensional printing type vehicle loading system, comprising: a two-degree-of-freedom sealed unloading device and a central control device; the central control device is connected to the two-degree-of-freedom sealed unloading device for unloading according to the target position, to control the transmission belt dust cover of the two-degree-of-freedom sealed discharge device to move back and forth along a predetermined path, and to control the second conveyor belt to swing up and down vertically around the first hinge. The invention can realize full-automatic and precise unloading, reduce dust, avoid the waste of time caused by the truck being aligned with the unloading end of the belt, and significantly improve the loading and unloading efficiency.

Owner:世邦工业科技集团股份有限公司

A material loading system

ActiveCN110884868BPrecise unloadingReduce pollutionConveyorsLoading/unloadingTruckMechanical engineering

Owner:世邦工业科技集团股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com