Continuous loading type ore loading machine for open-pit quarry

A loading and loading machine technology, which is applied in open-pit mining, loading/unloading, special mining, etc., can solve the problem that the loading machine cannot be loaded continuously, and achieve the effects of low noise, increased productivity and long life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The specific implementation will be described below in conjunction with the accompanying drawings.

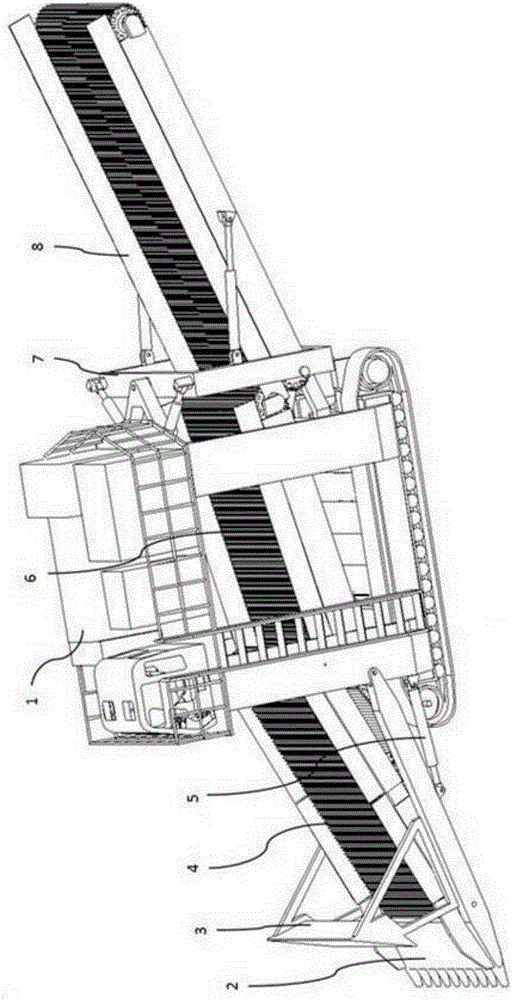

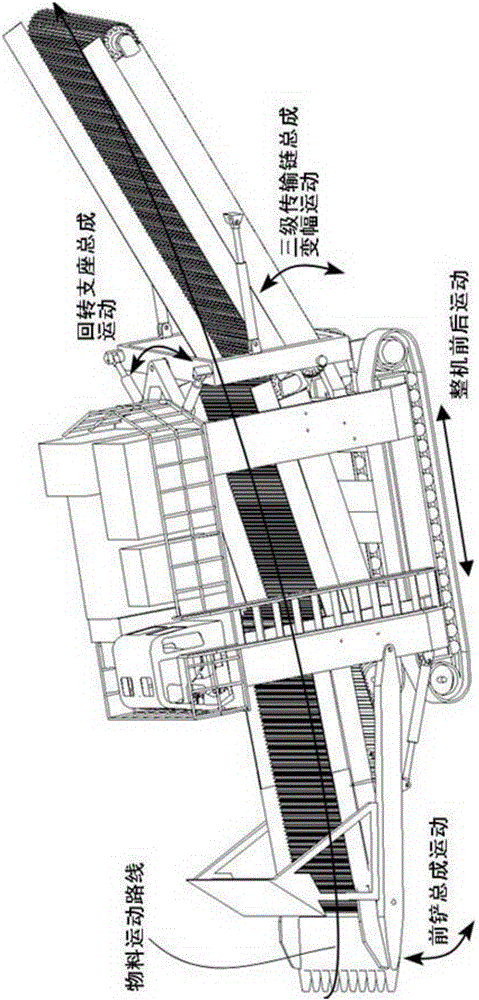

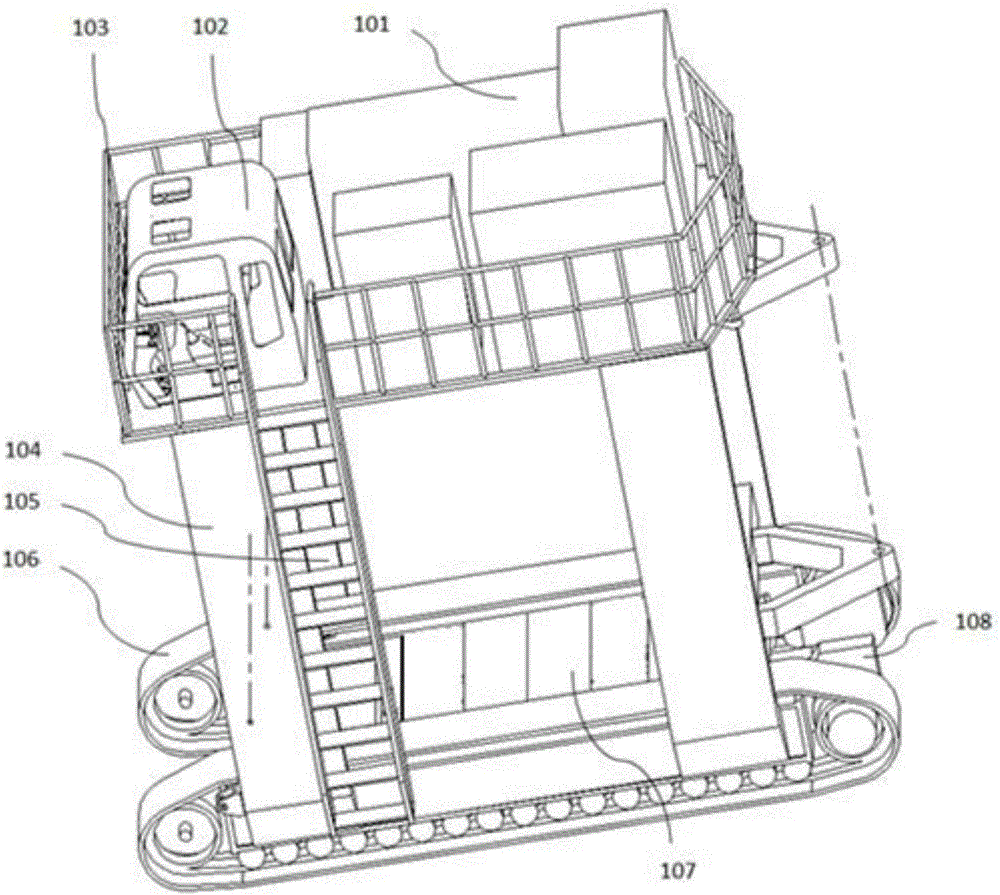

[0044] Such as figure 1 As shown, the ore loading machine in the present invention is used to load the mine car on the loose pile material formed after the ore rock is pierced and blasted. The first-stage transmission chain assembly 4 is installed on the rear end of the host 1 with a backward-protruding three-stage transmission chain assembly 8, and on the host 1 is installed a connection between the first-stage transmission chain assembly 4 and the third-stage transmission chain The secondary transmission chain assembly 6 of the assembly 8, the transmission chain front end of the secondary transmission chain assembly 6 is located below the transmission chain rear end of the primary transmission chain assembly 4, and the transmission chain rear end of the secondary transmission chain assembly 6 Located above the transmission chain front end of the three-stage transmissi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com