Continuous conveying system for statically metering materials

A conveying system and static metering technology, applied in the field of metering and conveying, can solve the problems of low metering accuracy, increasing the input and space occupied by the first conveyor belt 3 equipment, affecting the discharge efficiency of the static metering bin 1, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

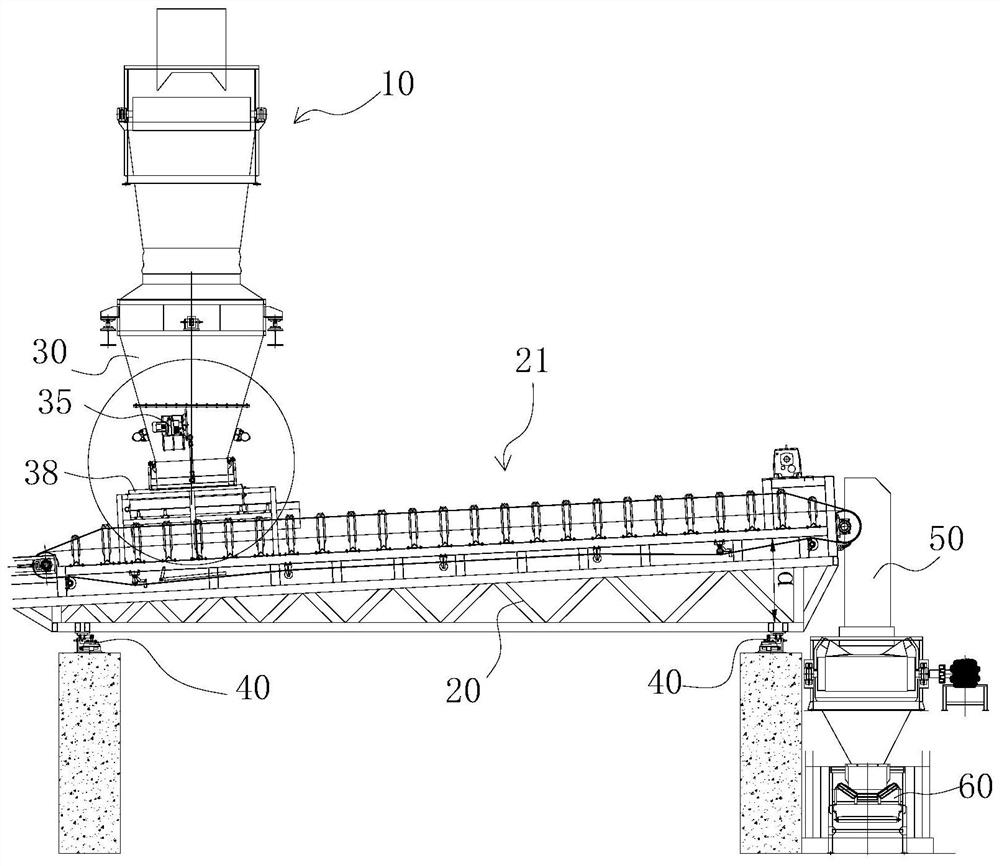

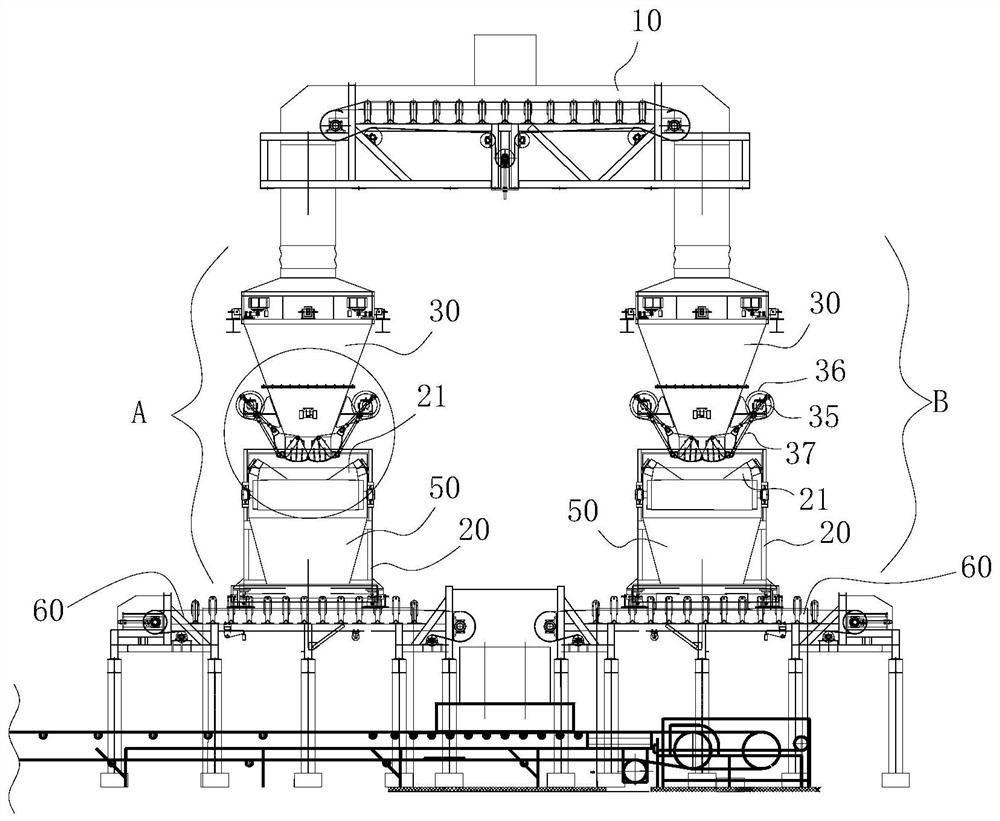

[0017] What first explained is the cargo ship arriving at the wharf or port. The powdery material carried by it is unloaded from the cargo hold through the conveyor belt, and first arrives at the two-way conveyor belt 10 of the present invention, and is alternately transported downstream by the two-way conveyor belt 10 of the present invention, and The two-way conveying belt 10 receives the materials from the cabin continuously. Firstly, the continuous conveying of the materials is realized; followed by the metering and conveying unit A and the metering and conveying unit B to carry out independent static metering of the received materials respectively, ensuring the metering accuracy, and then sent downstream.

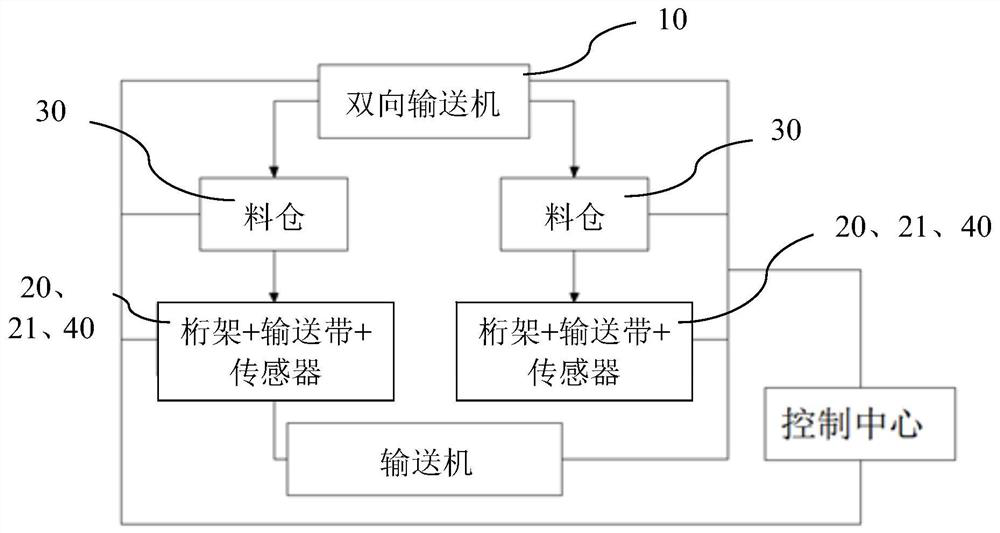

[0018] The specific solution of the present invention is that the continuous conveying system for statically metered materials includes a bidirectional conveying belt 10 connected below the discharge end of the unloading conveying belt, and the two ends of the bidirecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com