Concrete mixer

A technology for concrete mixers and mixing barrels, which is applied in cement mixing devices, mixing operation control, clay preparation devices, etc. It can solve the problems of severe grinding in the unloading hopper, high noise, and increased labor intensity, and achieve accurate unloading and noise reduction. , the effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0023]The present invention is further described below with reference to the drawings:

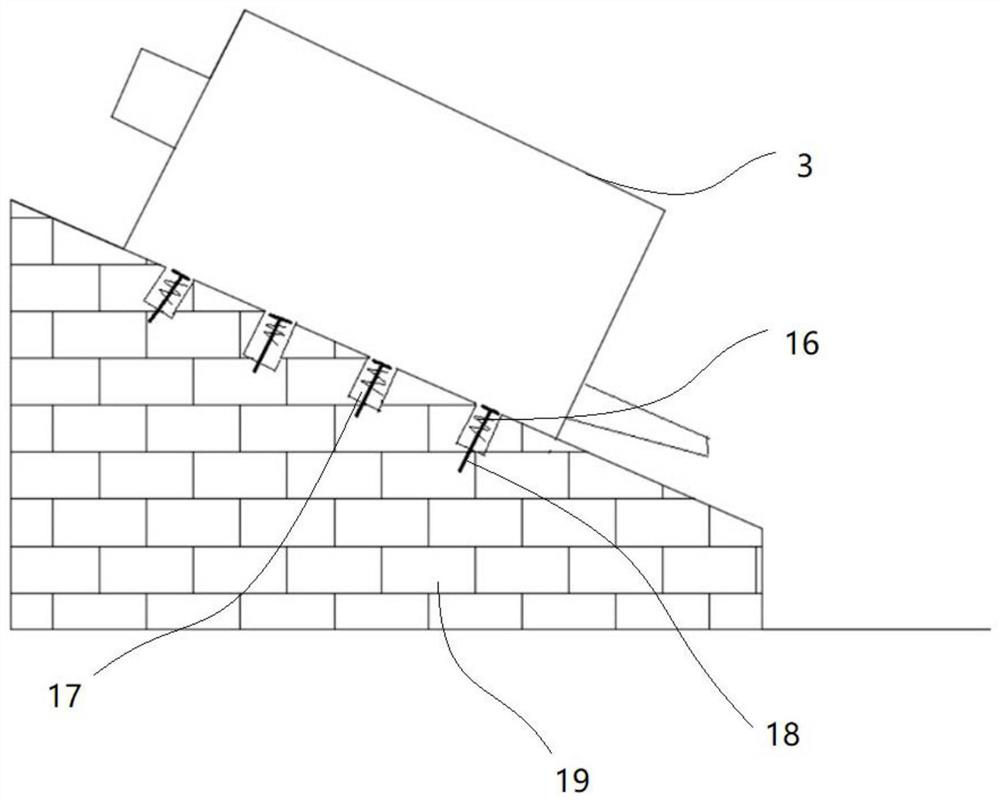

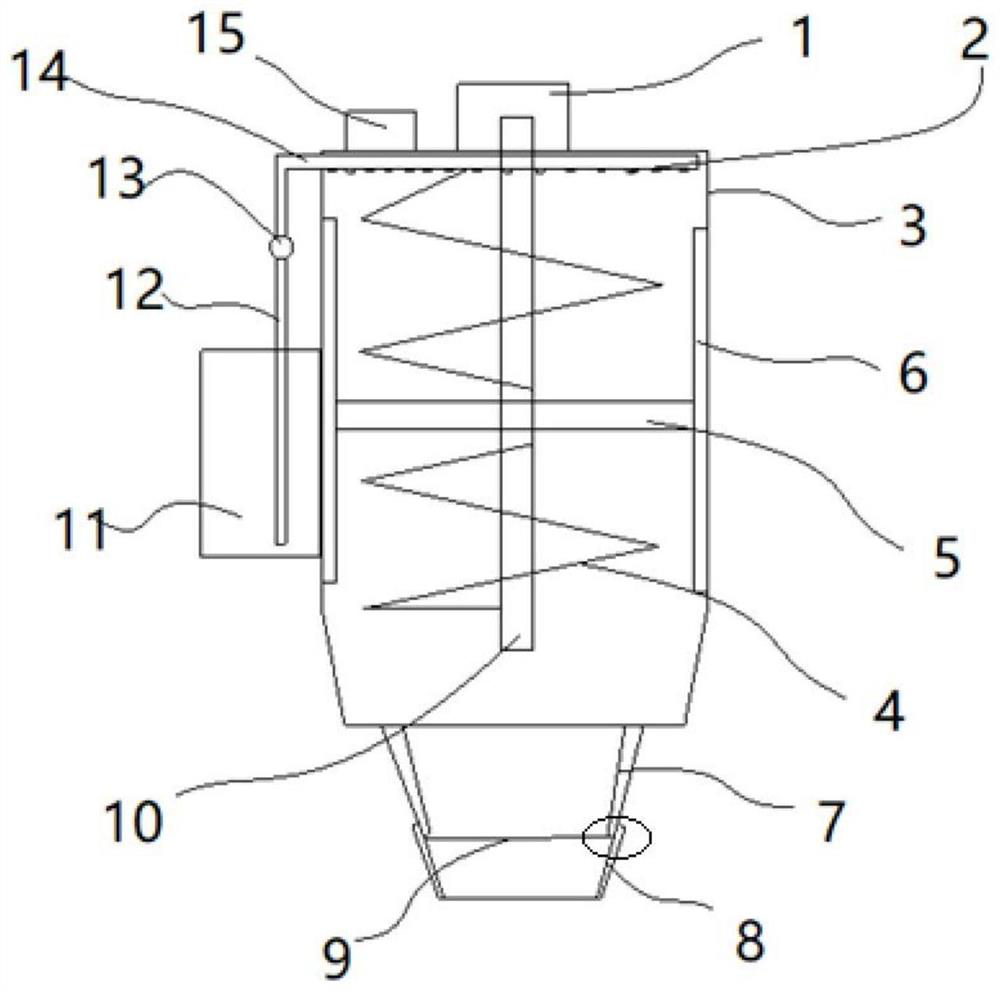

[0024]SeeFigure 1 to 4A concrete mixer comprising a stirring device, a cleaning device, a damping device, and a discharge device; the stirring means is fixed to the vibration damping device, and the discharge means is fixed to the bottom exit of the stirring device; the cleaning device is disposed at the stirring device The side, and the cleaning device is used to clean the inside of the stirring device; the upper surface of the vibration damping device is a ramp, the stirring device is disposed on the slope; the slope is advantageous for the material failure.

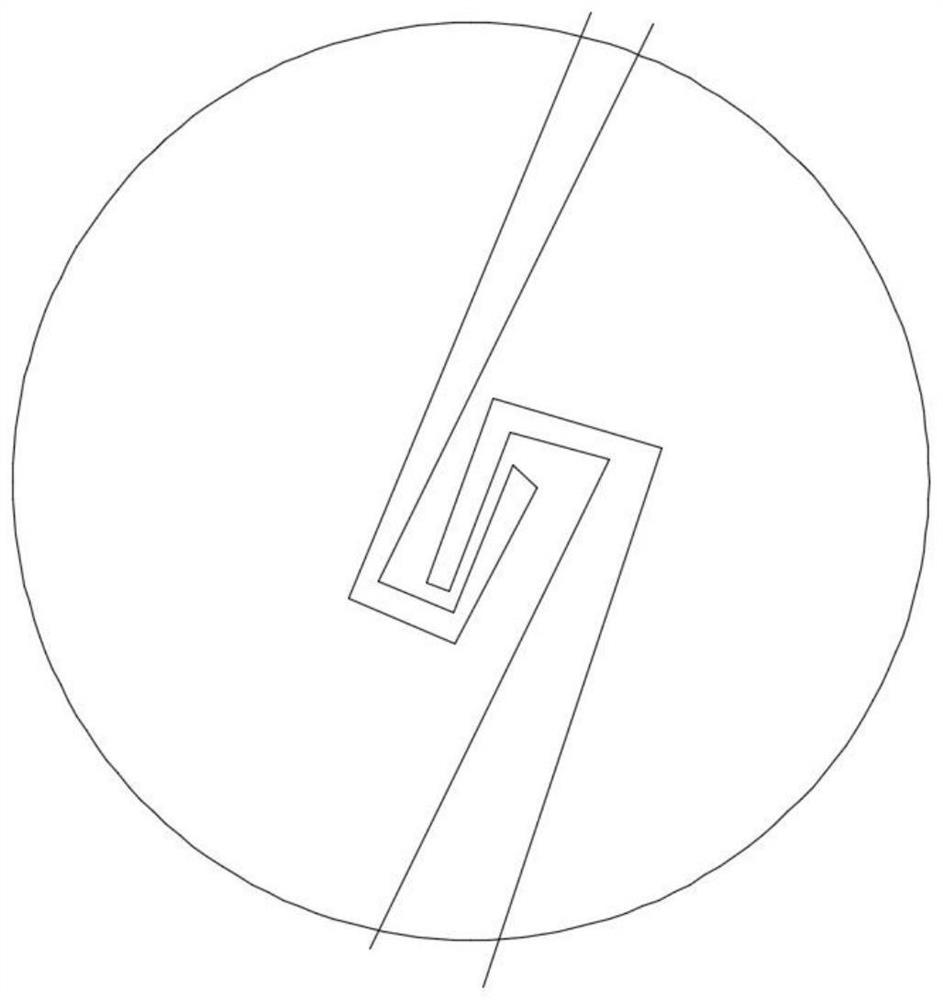

[0025]The stirring device includes a stirring tub 3, a drive motor 1, a spiral blade 4, and a stirring shaft 10, and the stirring shaft 10 is disposed inside the stirring tub 3; the driving motor 1 is disposed outside the stirring tub 3, and one end with the agitating shaft 10 Connect, the spiral blade 4 is disposed on the stirring shaft;

[0026...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com