Cardan joint back-extruding guiding structure suitable for 2000T automatic mechanical press

A technology of automatic machinery and guiding structure, applied in the direction of metal extrusion, metal extrusion forming tools, metal processing equipment, etc., can solve the problem of long production process, coaxiality can only reach 0.8-1.2, product sticking to the punch Top questions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

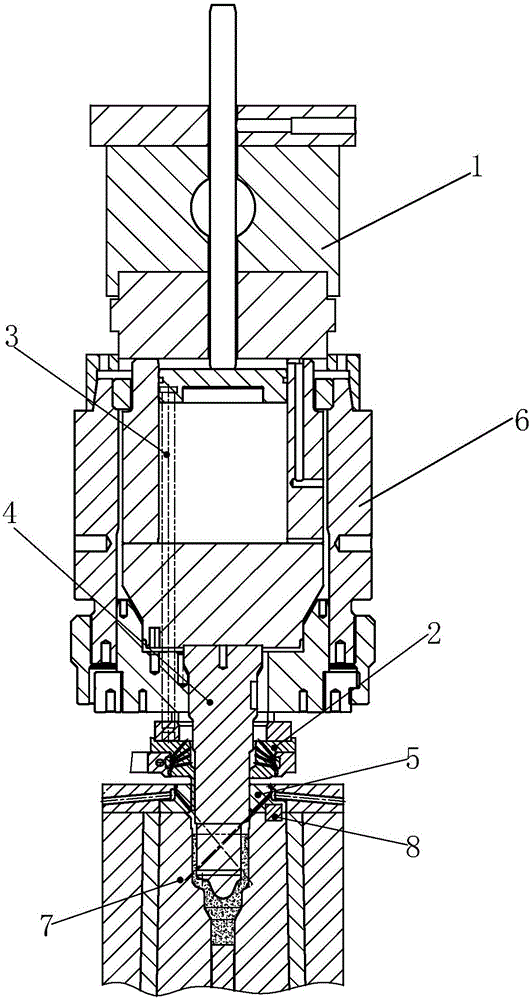

[0022] figure 1 It schematically shows a reverse extrusion guide structure suitable for a 2000T automatic mechanical press according to an embodiment of the present invention. like figure 1 As shown, this is suitable for the reverse extrusion guide structure of the universal joint of the 2000T automatic mechanical press, including the spray cooling guide device for the upper punch and the spray cooling guide device for the lower die.

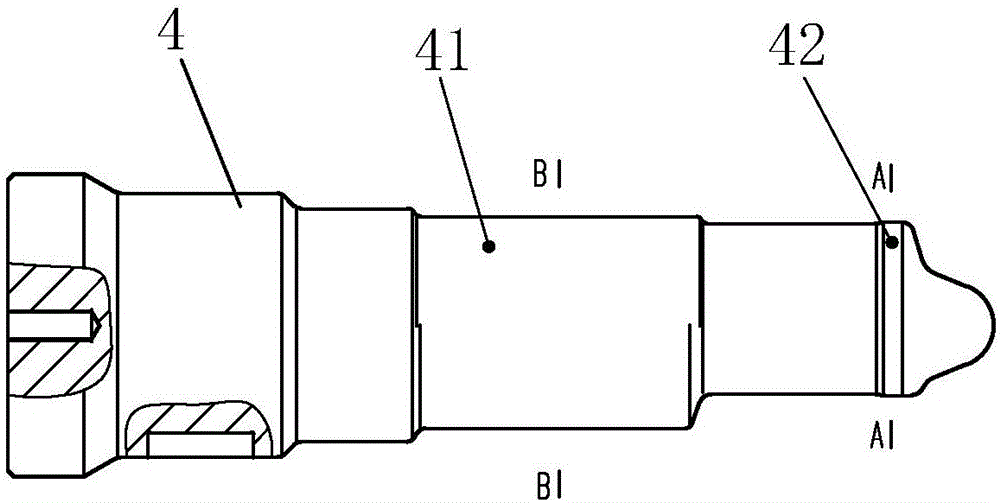

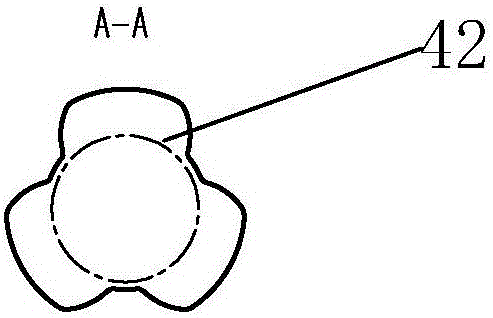

[0023] The upper punch spray cooling guide device includes an upper die body 1 and a discharge ring 2 . The split structure can save the cycle of manufacturing cost, and it is easy to replace and manufacture after damage. The upper mold body 1 and the unloading ring 2 are connected by a tie rod 3 . One end of the pull rod 3 is detachably connected to the upper mold body 1, and the other end of the pull rod 3 is detachably connected to the discharge ring 2. The upper mold body 1 is fixedly provided with a punch 4 . The punch 4 passes through...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com