Device used for accurate rear location and rapid unloading for numerically-controlled lathe

A CNC lathe and post-positioning technology, which is applied in the direction of metal processing machinery parts, metal processing, automatic in/out of workpieces, etc., can solve the problems of low processing efficiency, complex structure, and large number of pins, and achieve simple structure and convenient operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

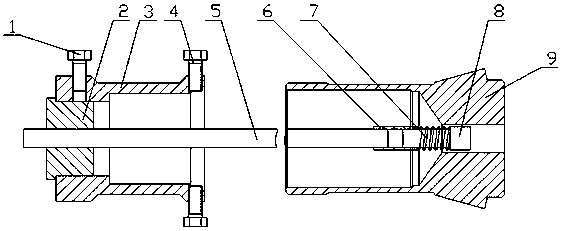

[0023] Below in conjunction with the accompanying drawings and preferred embodiments, the specific implementation, structure, features and functions of the device for precise post-positioning and fast unloading of CNC lathes according to the present invention will be described in detail as follows.

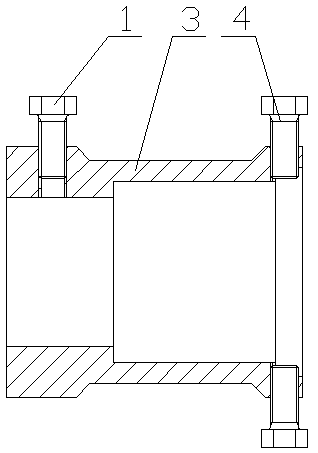

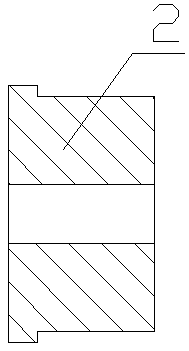

[0024] see Figure 1 to Figure 6 , the present invention is used for the accurate post-positioning of numerical control lathe and the device of fast unloading, comprises positioning assembly, ejector rod 5, unloading assembly, and the front portion and rear portion of ejector rod 5 are equipped with positioning assembly and unloading assembly respectively, wherein : The positioning device includes a jacket 3 and a clamping block 2, the front of the jacket 3 is set with a clamping block 2, the rear part of the outer peripheral surface of the jacket 3 is equipped with some bolts B4, and the ejector rod 5 is installed in the through hole of the clamping block 2 and runs through the ja...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com