Super capacitor liquid injection method and liquid injection device

A supercapacitor and liquid injection device technology, which is applied in the field of capacitor manufacturing, can solve the problems of inaccurate control, electrolyte cannot fully fill the liquid injection volume, etc., to improve the efficiency of liquid injection, reduce the auxiliary time of loading and unloading materials, and have a simple and practical structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

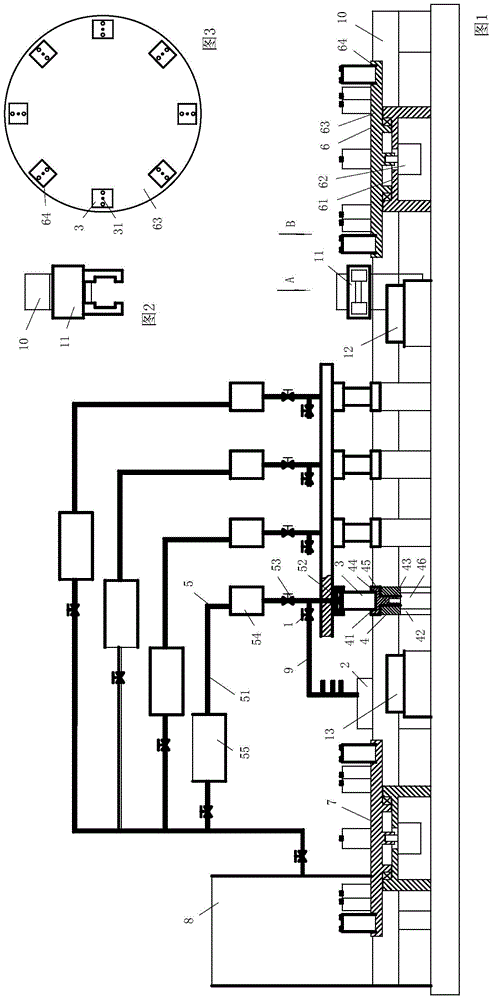

[0015] The present invention will be further described below in conjunction with the accompanying drawings.

[0016] as attached figure 1 , attached figure 2 , attached image 3 Shown: a supercapacitor liquid injection method, including the following steps: (1) connect the vacuum on-off valve 1, through the liquid injection hole 31 of the supercapacitor 3, use the vacuum pump 2 to extract the air in the supercapacitor 3 for the first time to achieve a vacuum 0.7pa, and keep it for 12 minutes; (2) while vacuuming for the first time, use diaphragm pump 55 to pump the electrolyte that accounts for 85% of the total injection volume from electrolyte tank 8 into liquid storage tank 54; (3 ) After the first vacuuming is completed, disconnect the vacuum on-off valve 1 and connect the infusion on-off valve 53, so that the electrolyte in the liquid storage tank 54 is sucked into the supercapacitor 3 under negative pressure and soaked for 4 minutes, so that The electrolyte is fully f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com