Gap detection device of safety airbag

A technology of airbags and detection devices, which is applied in the direction of mechanical clearance measurement, etc., can solve problems such as low precision, low efficiency, and large tolerances of measurement points, and achieve the effects of simple operation, high detection efficiency, and improved work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

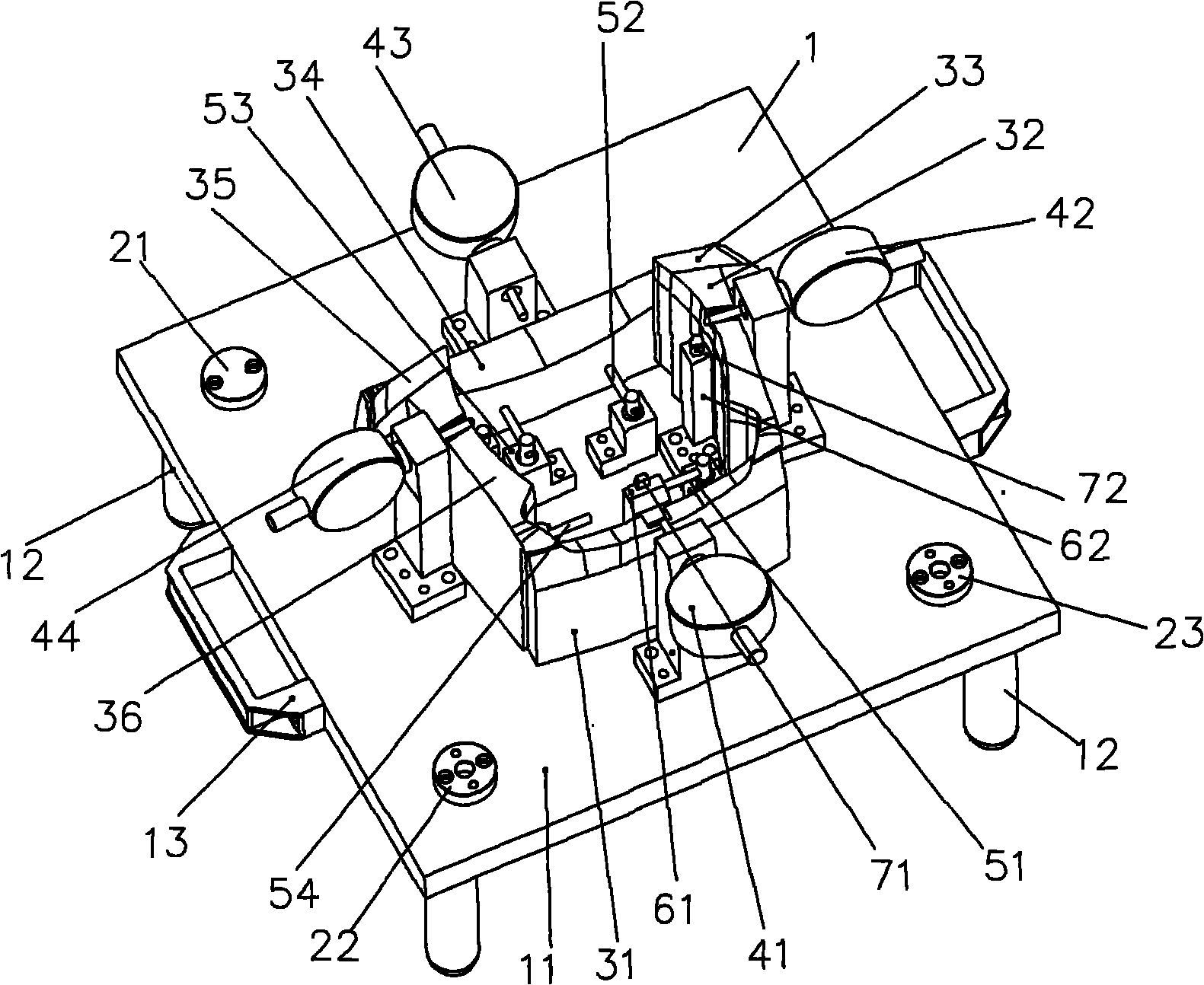

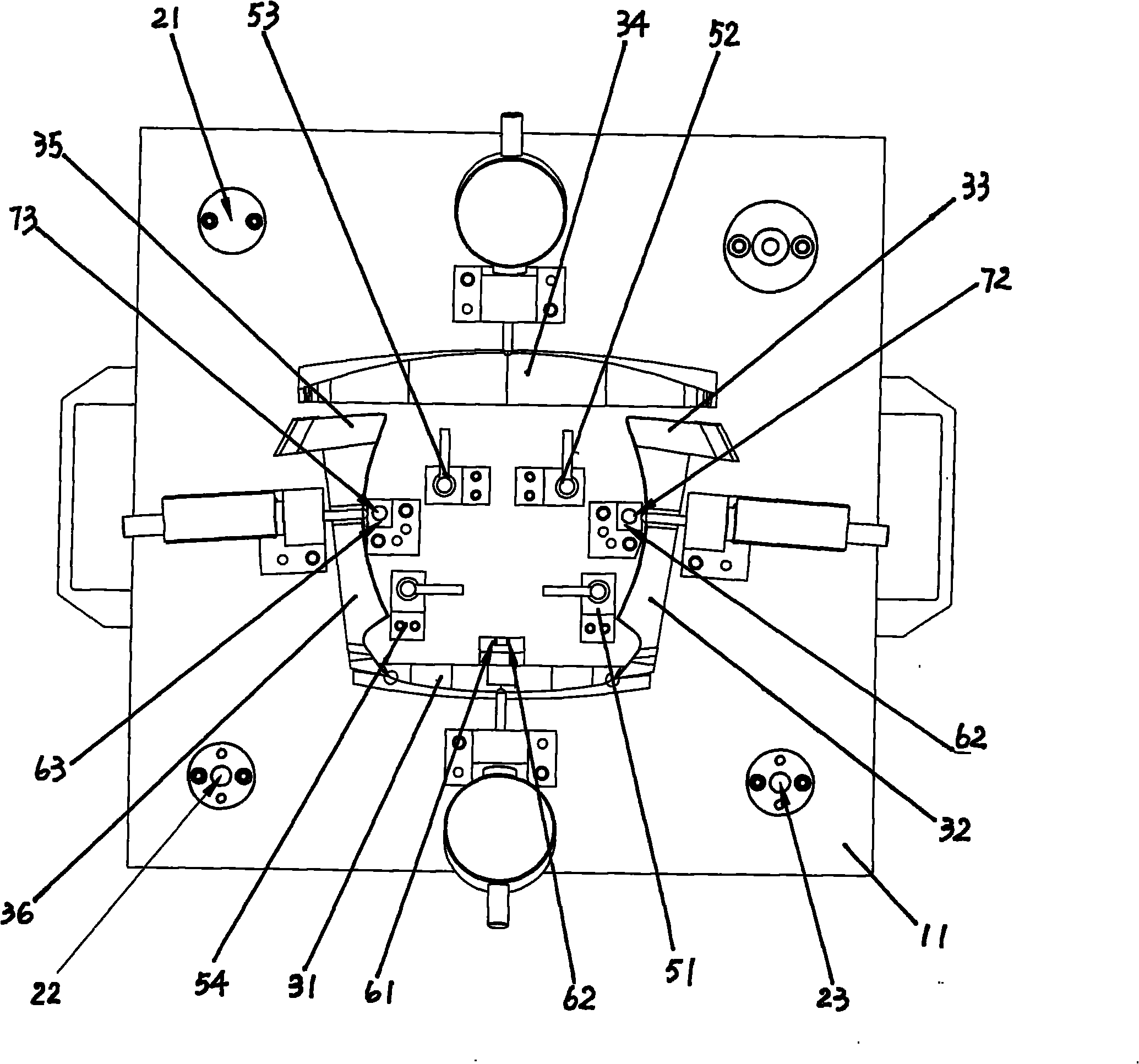

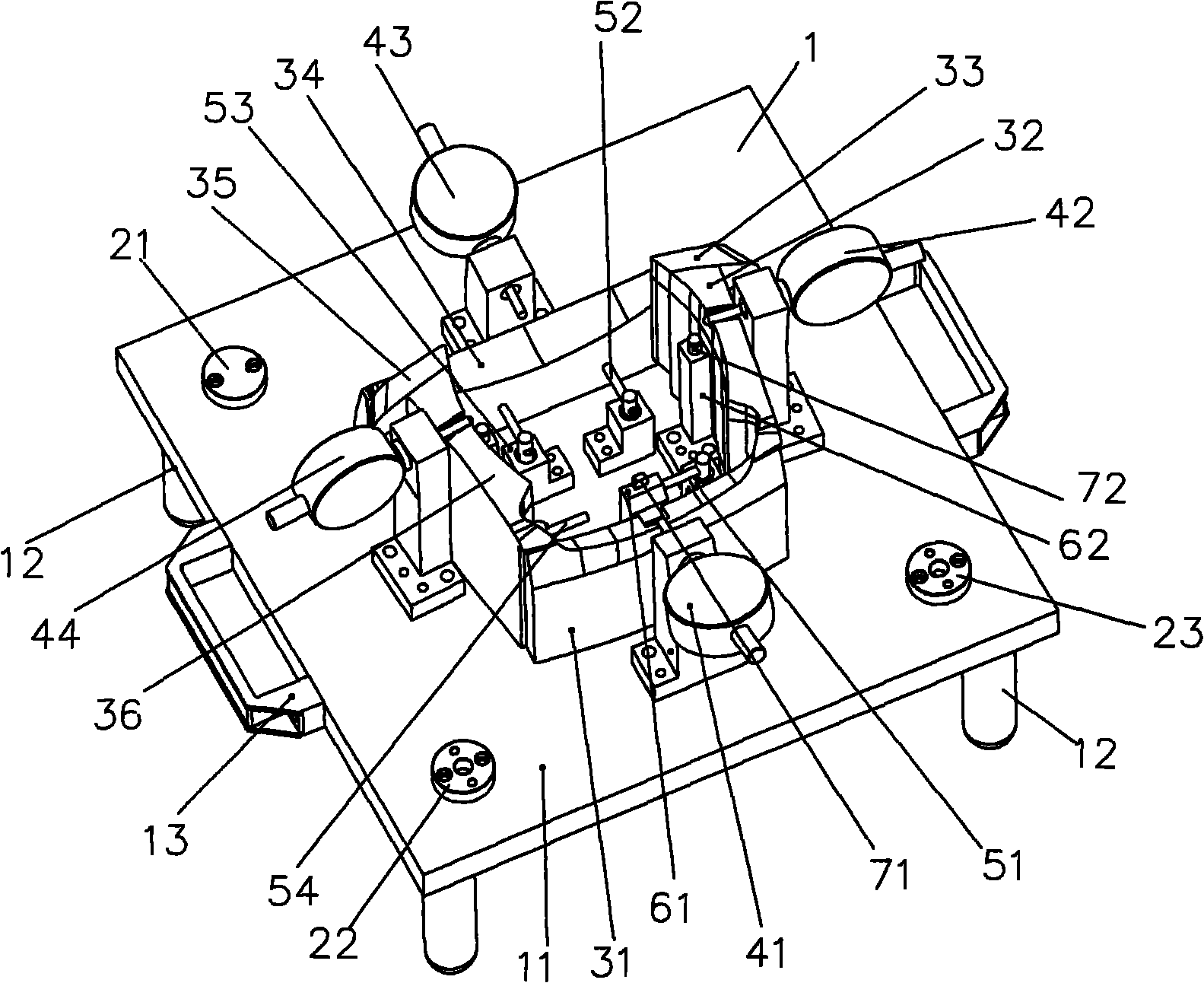

[0022] see figure 1 , figure 2 , the safety airbag clearance detection device of the present invention, comprises base 1, three reference blocks 21,22,23, six simulation blocks 31,32,33,34,35,36, four dial gauges 41,42,43 , 44, four clamps 51, 52, 53, 54 and three positioning posts 61, 62, 63.

[0023] The base 1 includes a square bottom plate 11 , four bottom plate feet 12 and two handles 13 connected to both sides of the bottom plate 11 .

[0024] Three reference blocks 21 , 22 , 23 are respectively arranged on three corners of the square bottom plate 11 . The flatness and verticality requirements of the three reference blocks are 0.02mm, and the flatness requirements between each reference block are 0.05mm.

[0025] Six simulation blocks include a first simulation block 31, a second simulation block 32, a third simulation block 33, a fourth simulation block 34, a fifth simulation block 35 and a sixth simulation block 36. 31, 32, 33, 34, 35 , 36 are sequentially connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com