Automotive steering intermediate shaft torsion gap detection device

A detection device, intermediate shaft technology, applied in the direction of measuring devices, instruments, etc., can solve the problems of large personnel operation errors, inability to obtain clearance curves, lack of scientificity and accuracy, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to enable those skilled in the art to better understand the technical solution of the present invention, the solution will be further described in detail below in conjunction with specific embodiments.

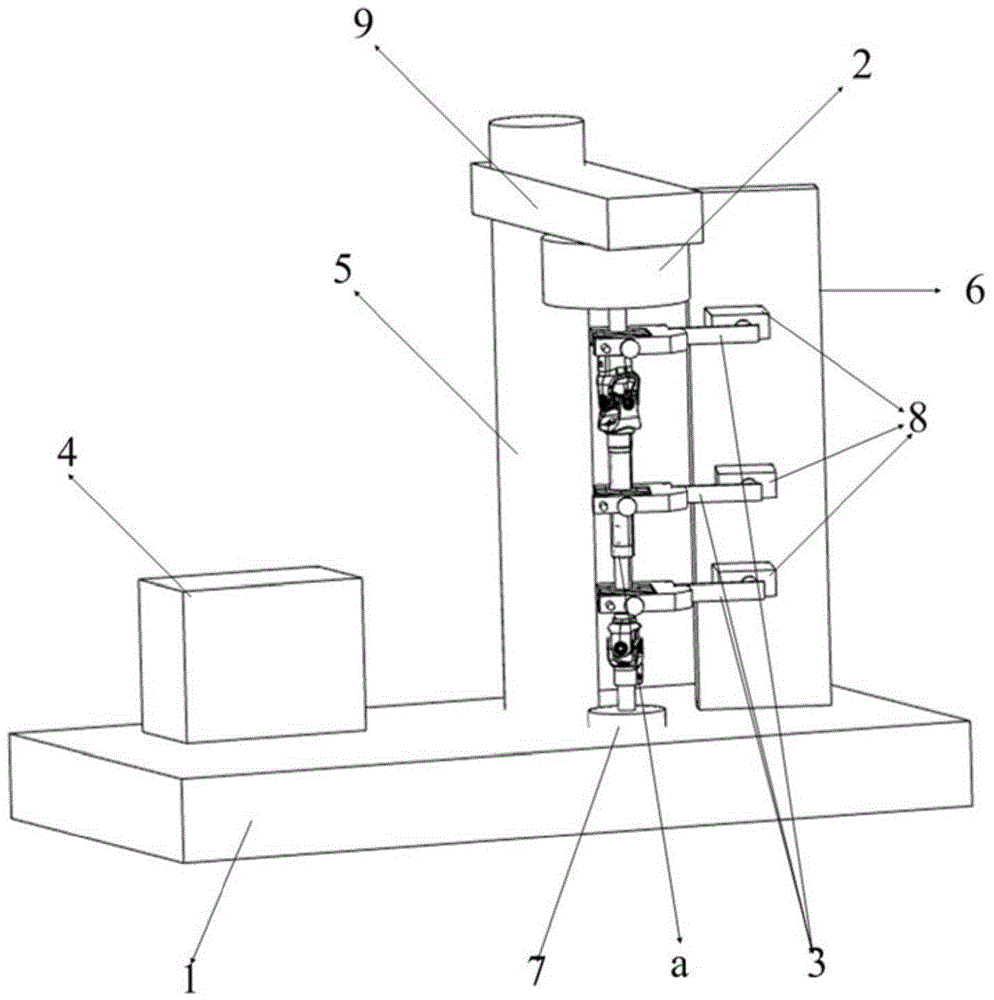

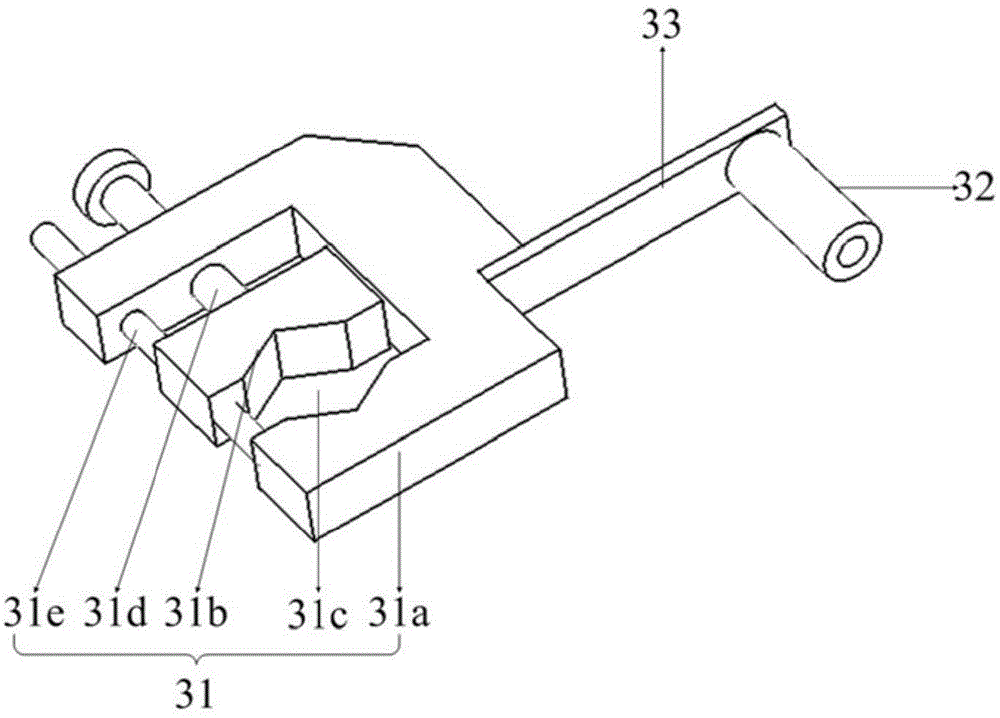

[0025] reference figure 1 with figure 2 The embodiment of the present invention provides an automobile steering intermediate shaft torsion gap detection device, which includes a detection base 1, a drive connection part 2 connected with the driving end of the intermediate shaft, and at least one set of clamping parts 3; the detection base 1 is fixed There are a PC 4, a fixed column 5 connected to the drive connection portion 2, a sensor bracket 6 and a fixed connection portion 7 connected to the fixed end of the intermediate shaft. The sensor bracket 6 is fixed with the clamping portion 3 A corresponding displacement sensor 8.

[0026] When in use, the intermediate shaft a is fixed to the detection device through the drive connection portion 2 and the fixed connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com