Leveling method of circular saw web base body

The technology of circular saw blade and base body is applied in the field of leveling the base body of circular saw blade, which can solve the problems of center hammering, reducing the performance of the saw blade base body, turning over, etc., to achieve the effect of improving rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Take the base leveling of a circular saw blade with a diameter of 1600mm as an example:

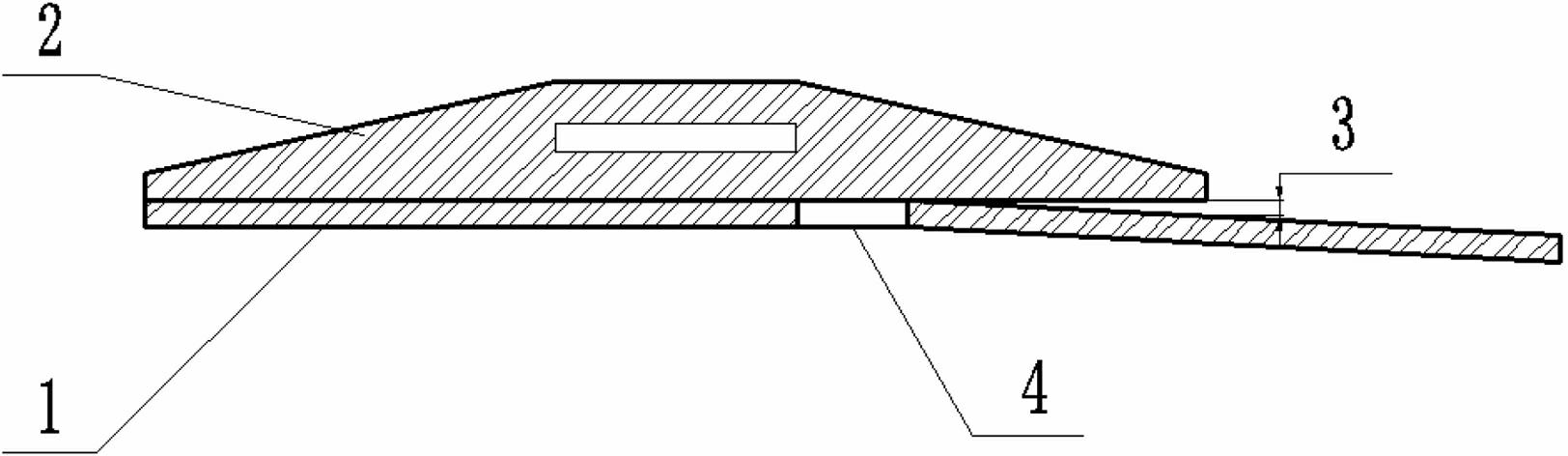

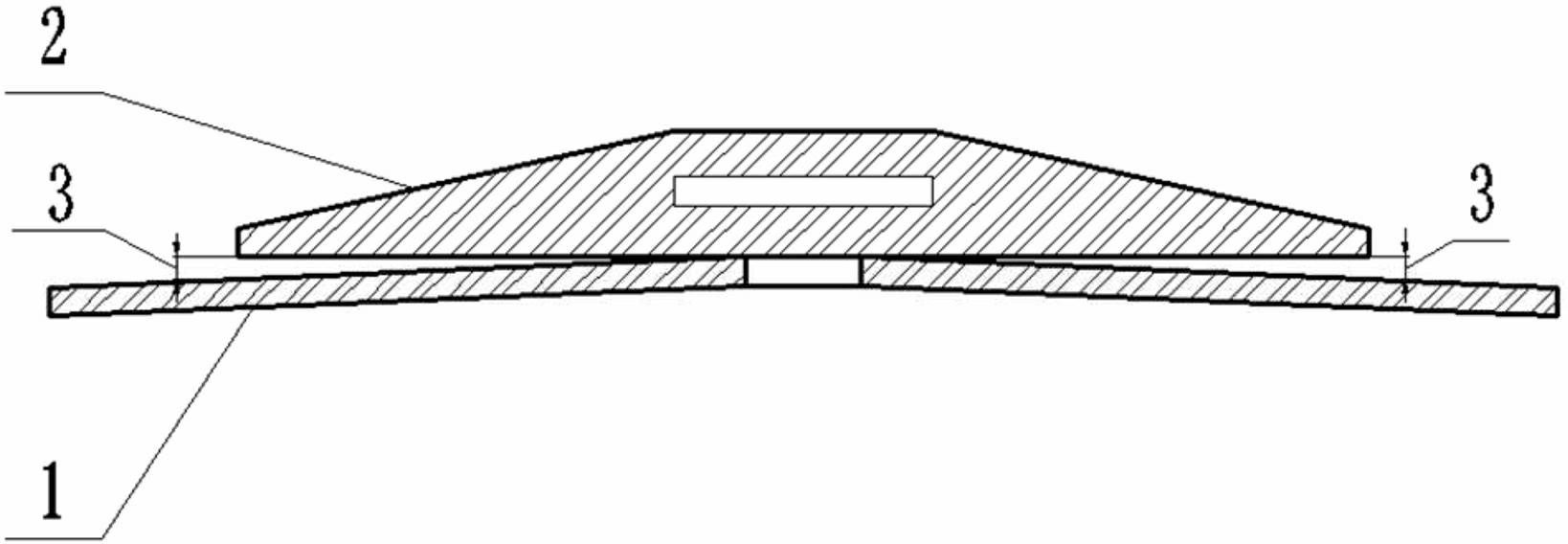

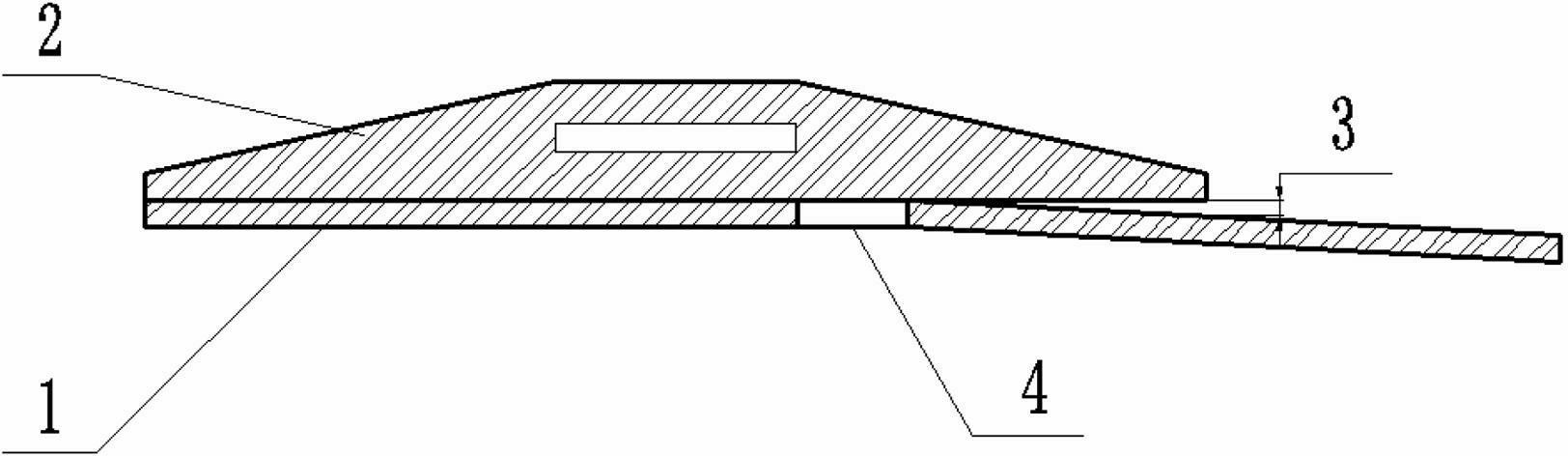

[0021] After the circular saw blade base 1 is lifted, the gap detection is performed with a flat ruler 2 whose total length is 2 / 3 of the diameter of the circular saw blade base (1). The leveling ruler 2 shall detect the gap distribution within the diameter range of 2 / 3 of the circular saw blade base 1 and the symmetrical range of the center hole 4 of the circular saw blade base 1, and then carry out rolling or leveling hammers at specific positions according to the test results. Click Leveling.

[0022] Depend on figure 1 It can be seen that when the circular saw blade base 1 is lifted, the square ruler 2 must detect the gap distribution within the diameter range of 2 / 3 of the circular saw blade base 1, when figure 1 The width of gap 3 shown is ideal when the gap is 2-4mm, and there is no need for leveling work; when it is seamless or when the gap width is less than 2mm, it mean...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com