Carrier packaging process of three-way catalytic converter and carrier pressing machine

A three-way catalytic converter and encapsulation technology, which is applied in metal processing, manufacturing tools, metal processing equipment, etc., can solve the problems of cylinder misalignment, poor roundness of cylinder, damage of liner, etc., so that it is not easy to crush , easy production, uniform deformation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

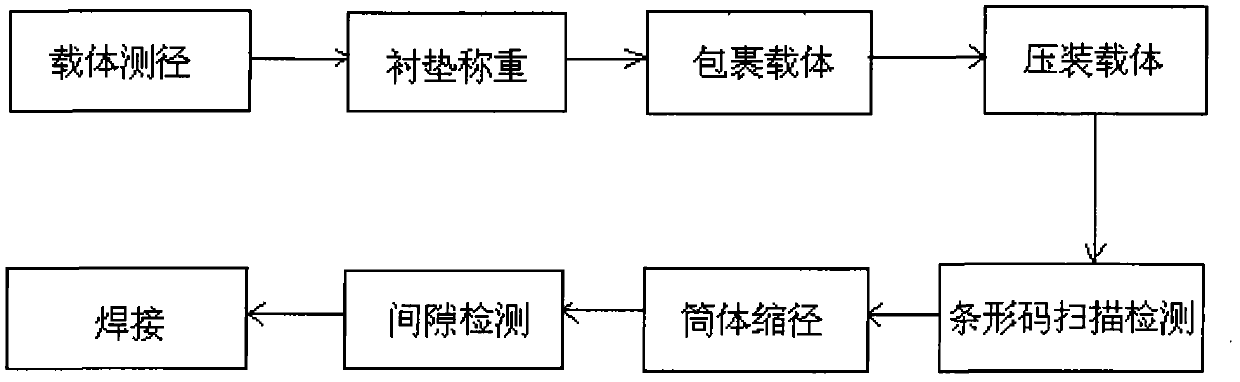

[0029] Such as figure 1 A carrier encapsulation process of a three-way catalytic converter is shown, and the process includes the following steps:

[0030] a) Carrier diameter measurement: use a laser caliper to measure the diameter of the carrier of the three-way catalytic converter without contact, the measurement accuracy is 0.01mm, input the carrier diameter data into the barcode machine correspondingly, and generate a black barcode through the barcode machine, and then Printed out and posted on the carrier end face;

[0031] b) Liner weighing: weigh the weight of the liner with a weighing accuracy of 0.01mm, input the weight data of the liner into the barcode machine correspondingly, and generate a red barcode through the barcode machine, then print it out and paste it on the liner on the side;

[0032] c) Wrapping the carrier: wrapping the side wall of the carrier with a liner;

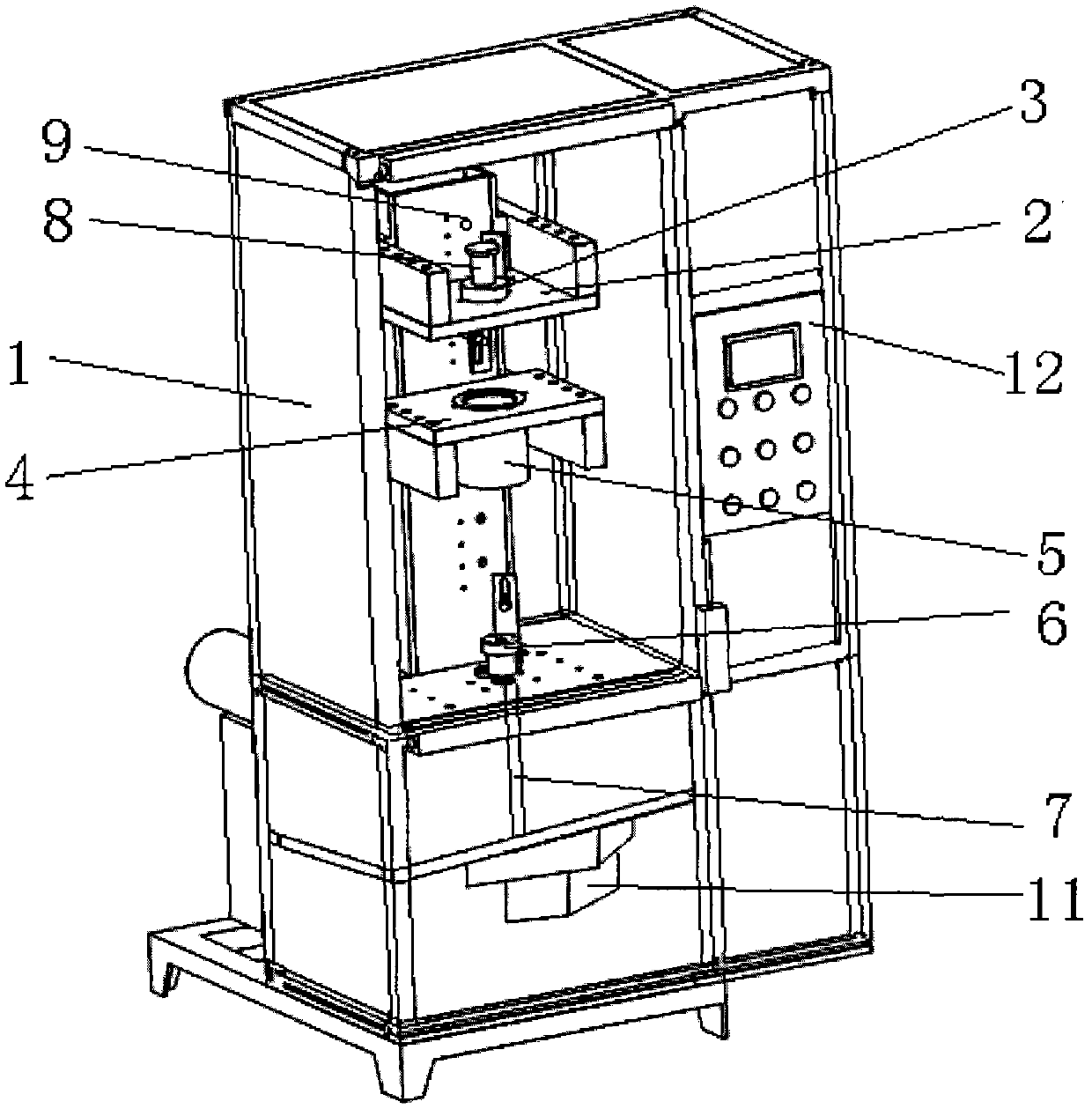

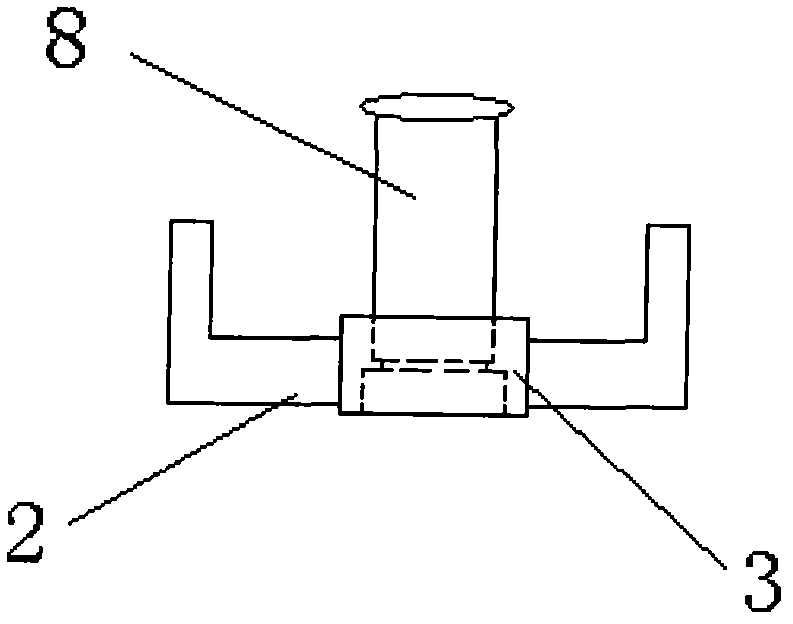

[0033] d) Press-fit carrier: put the carrier wrapped with the liner on the tray of the ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com