Method for improving detecting precision of continuous casting hydraulic fanshaped section roll gap through online roll gap apparatus

A detection accuracy, sector-shaped technology, applied in the configuration of indicating equipment/measuring equipment, casting equipment, manufacturing tools, etc., can solve the problems of complex equipment structure, the influence of continuous production characteristics of casting machines, and the influence of roll gap meter detection accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

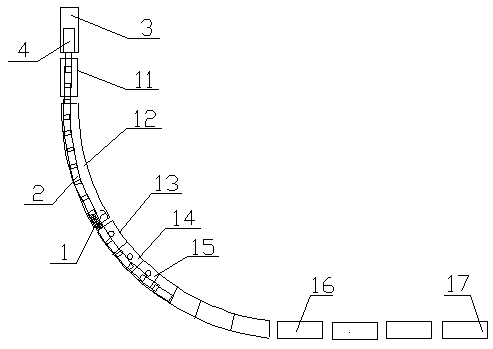

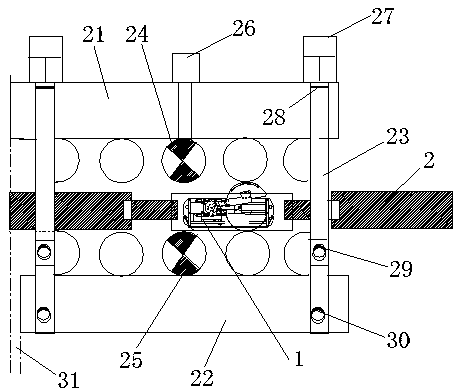

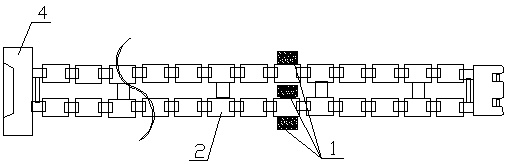

[0029] The roll gap control accuracy of slab continuous casting is the most important parameter of a casting machine, which is generally required to be within the range of ±0.5mm, and there should be no sudden changes. The basic composition of a general vertical bending slab continuous casting machine includes a crystallizer, a foot roll, a vertical bending section (also known as a support and guide section), and a sector section. The gap between the upper and lower rollers is called the roll gap, and the roll gap is the control Key parameters for slab shape, some surface quality defects and most slab internal defects. The roll gap structure of the crystallizer foot roll and the vertical bending section is fixed (non-hydraulic); in order to meet the process requirements such as light reduction and large reduction, the roll gap control structure of hydraulic pressure and position sensor is generally used in the fan section.

[0030] The roll gap formation of this sector is very...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com