Robot smart arm joint drive and reduction device thereof

A reduction gear, robot technology, applied in transmission, gear transmission, manipulator and other directions, can solve the problems of limiting the design effect and function of dexterous arm, low mechanical efficiency of worm gear reducer, limited output torque of planetary reducer, etc. Great implementation value, compact structure, simple control effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

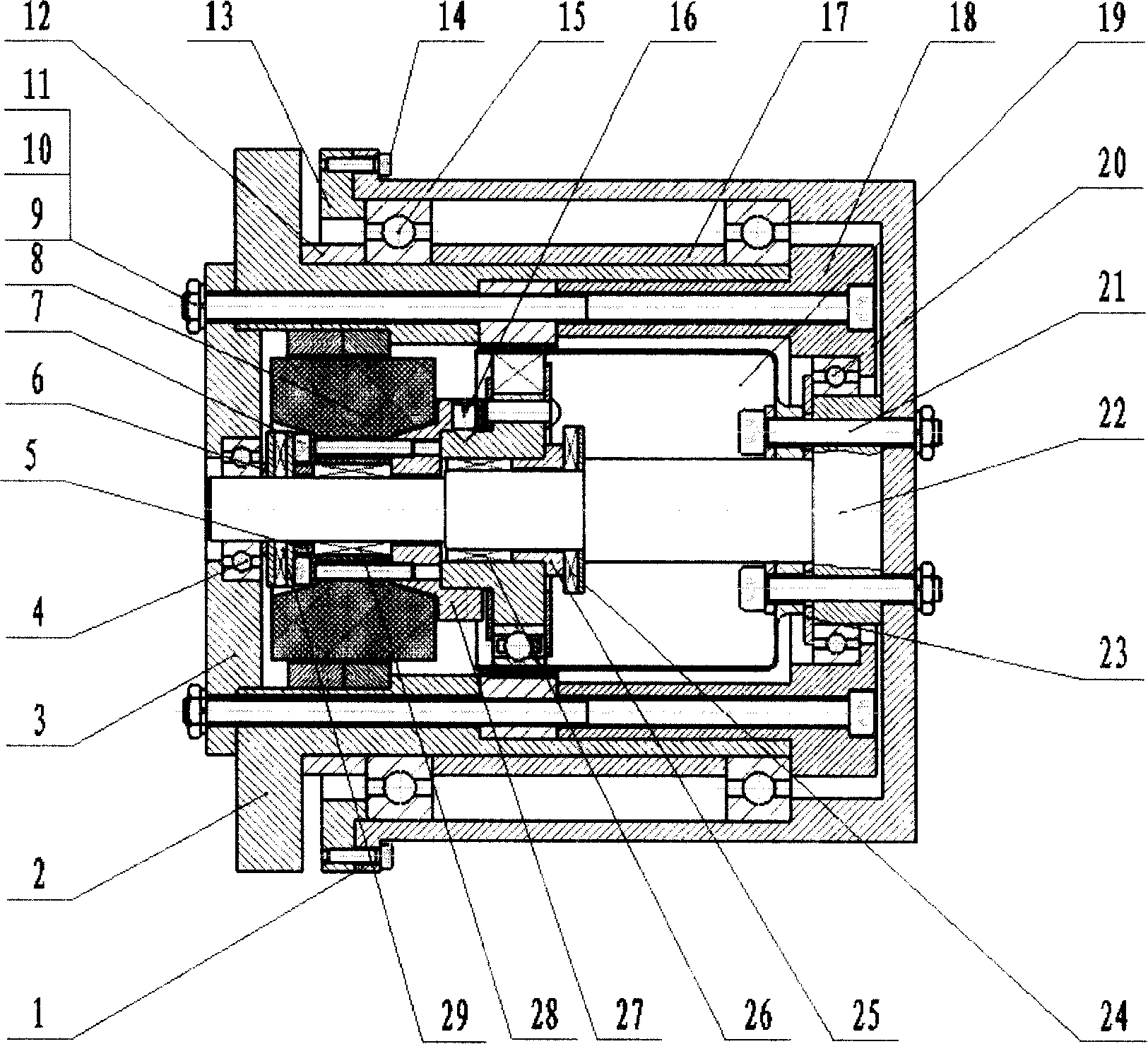

[0008] figure 1 is an embodiment of the present invention. Such as figure 1 Shown, the embodiment of the present invention is: robot dexterous arm joint drive and deceleration device thereof, by flange (1), the first motor fixing frame (2), end cover (3), deep groove ball bearing (4) ( 15)(20), washer(6), hexagon socket cap screw(7)(9)(14)(21), permanent magnet DC torque motor(8), hexagon thin nut(10), spring washer(11 ), the first sleeve (12), the bearing cover (13), the tightening screw (16), the second sleeve (17), the second motor fixing frame (18), the harmonic reducer (19), the Shaft (22), retaining ring (23), needle roller bearing (24) (28), thrust needle roller bearing (26) (29), connecting flange (27) is formed. The stator of the permanent magnet DC torque motor (8) is pasted and fixed on the first motor fixing frame (2) by an adhesive, the rotor of the motor is connected with the connection flange (27) by screws, and the connection flange (27) is connected by fast...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com