Rotor head pulling and twisting strip type propeller hub for helicopter blade dynamic balance test table

A test bench and helicopter technology, applied in the field of helicopter testing, can solve problems such as disadvantage, poor hinge moment accuracy, and large end bearing size.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

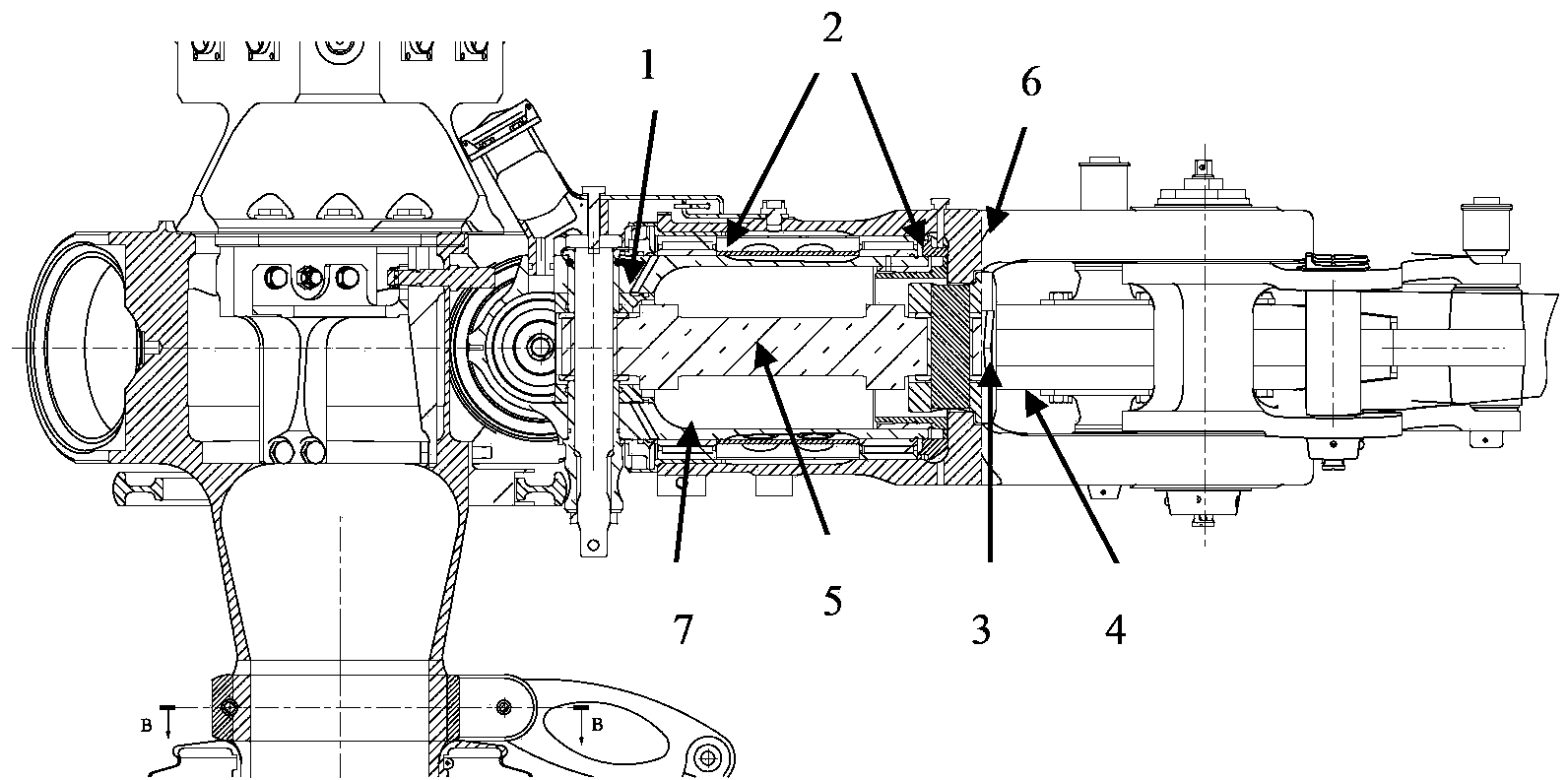

[0011] Helicopter blade dynamic balance test bench The type of the twisted bar hub of the rotor head is as follows: figure 1 As shown, the torsion bar 5 is used to withstand the centrifugal force of the blade, and the metal needle bearing 2 is used to realize the pitch change of the hub. Twist strips can generally be made by winding and fixing thin steel wires, or by stacking and fixing multiple layers of steel sheets, and are manufactured by professional manufacturers. The tensile modulus of the torsion bar is high, but its torsional stiffness is very small in the torsional direction, and the torsional stiffness value is very stable and will not change with the change of the ambient temperature. Therefore, the hinge moment of this type of propeller hub is very small and stable, which is conducive to the realization of high-precision measurement of the blade hinge moment. Moreover, since the needle roller bearing 2 does not bear centrifugal force, it has a long service life, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com