Pillow block system with tapered roller bearings

一种锥形滚子、轴承的技术,应用在球形外径锥形滚子轴承组件的轴承系统领域,能够解决旋转密封件托架迷宫环不能移除、无法接近滚子列、轴承滚道和滚子表面检测困难等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The following detailed description illustrates the invention by way of example and not limitation. This description clearly enables one skilled in the art to make and use the invention, describing several embodiments, adaptations, variations, alternatives, and uses of the invention, including what is presently believed to be the best mode of carrying out the invention.

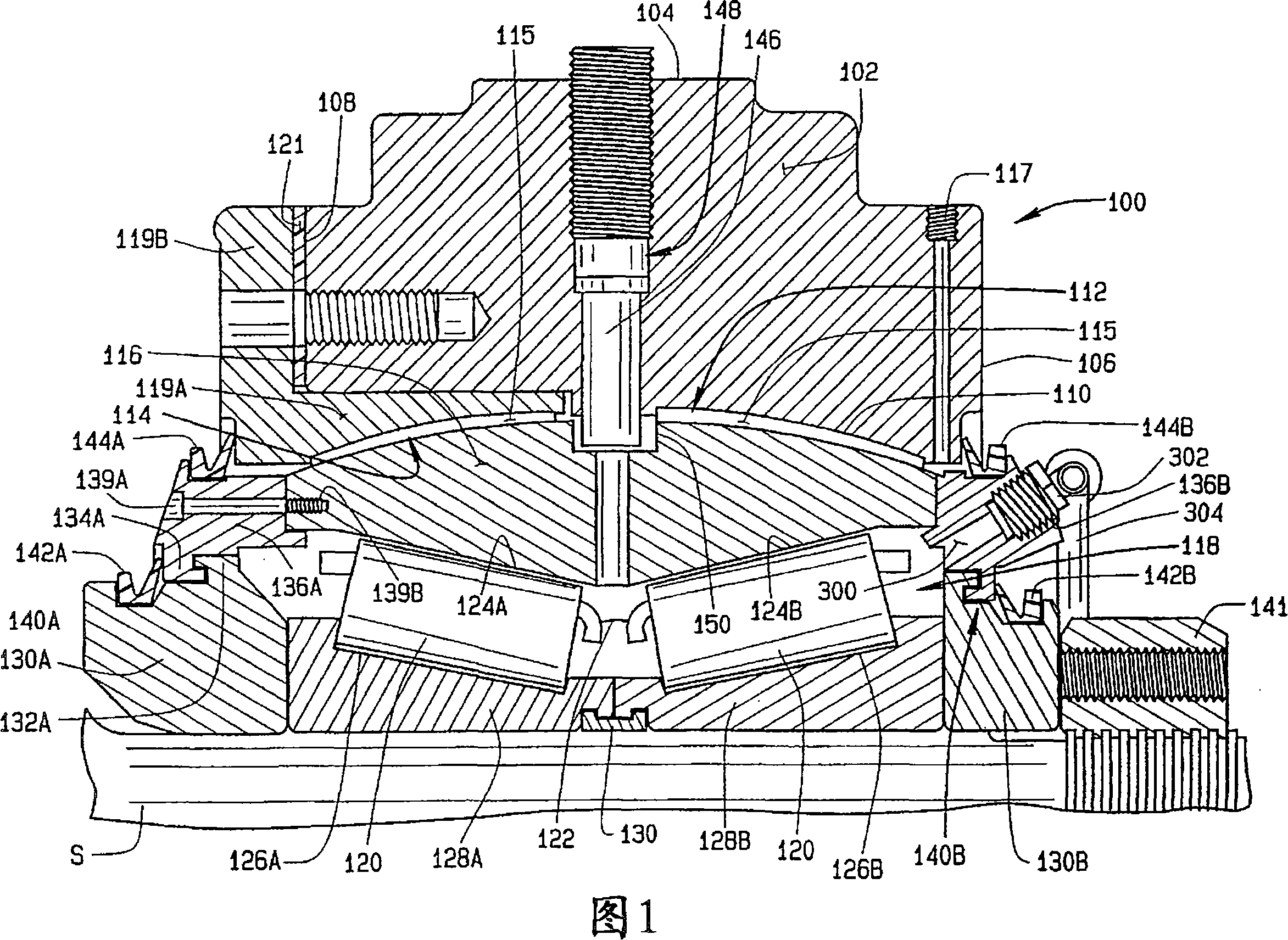

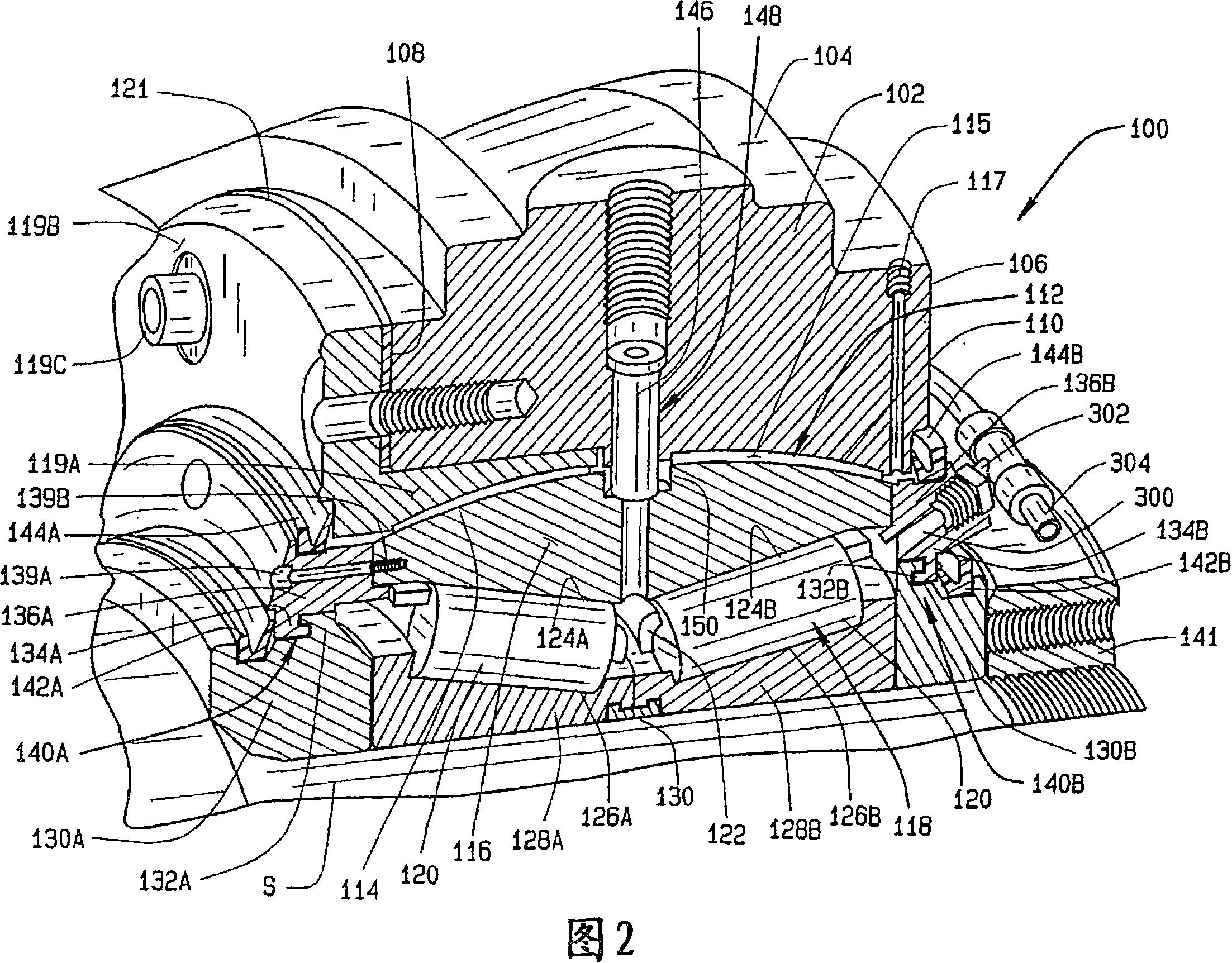

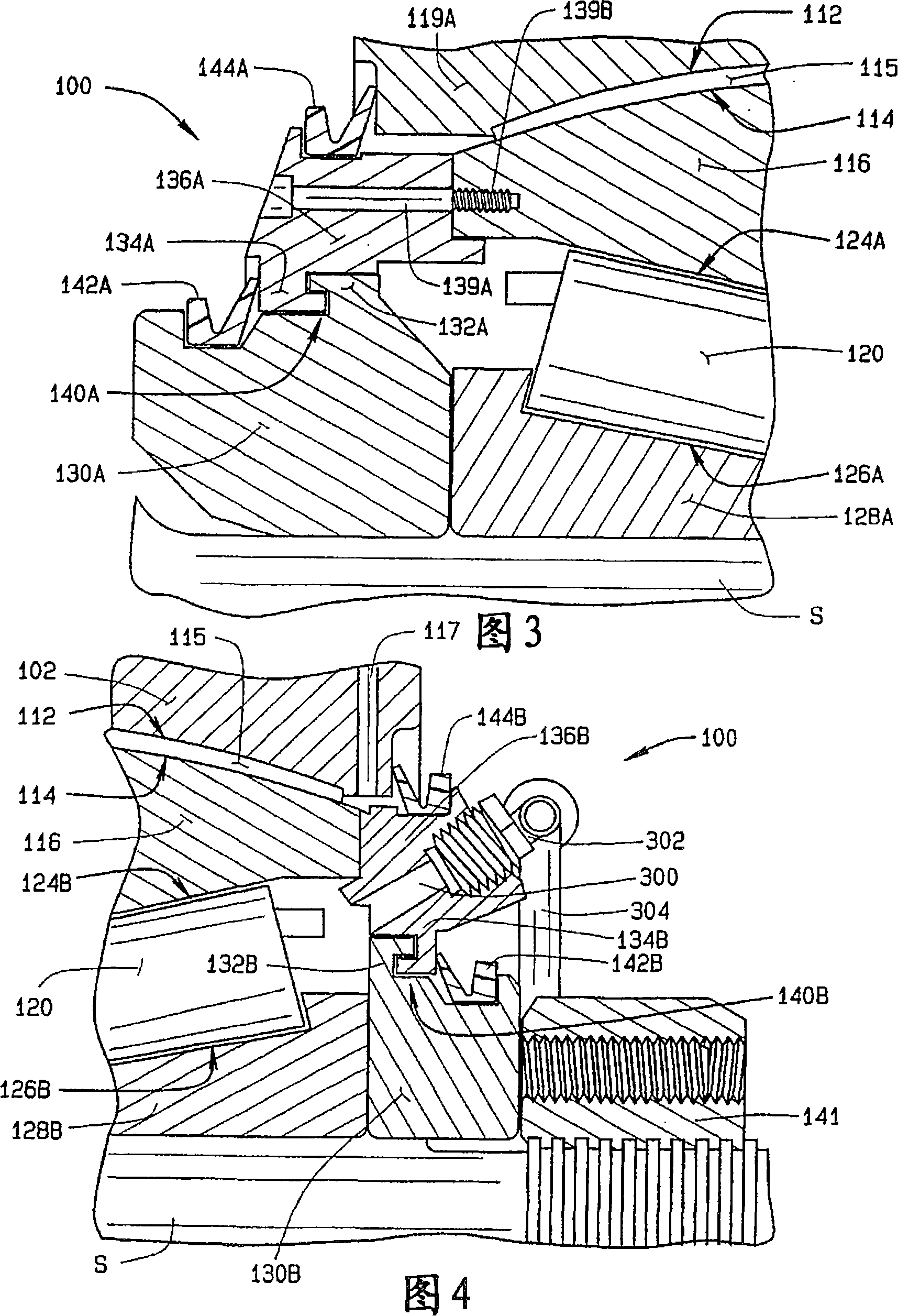

[0021] Referring to FIGS. 1-4 , a first exemplary embodiment of a bearing assembly of the present invention for supporting a wind turbine main shaft is shown generally at 100 . The bearing assembly 100 includes a pillow block housing 102 having an outer surface 104 , a gearbox end face 106 and a rotor end face 108 . The outer surface 104 is configured with suitable attachments to couple the pillow block bearing assembly 100 to a support structure (not shown), preferably with a TDO (TNA) style mounting configuration which due to its large The effective spread and indirect mounting styles enable relative...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com