Automatic assembling machine of needle roller of planet wheel

A planetary gear and assembly machine technology, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve problems such as affecting product quality and enterprise efficiency, missing needle rollers or gaskets, low work efficiency, etc. The effect of the probability of occurrence of qualified products, improved efficiency, and easy maintenance and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

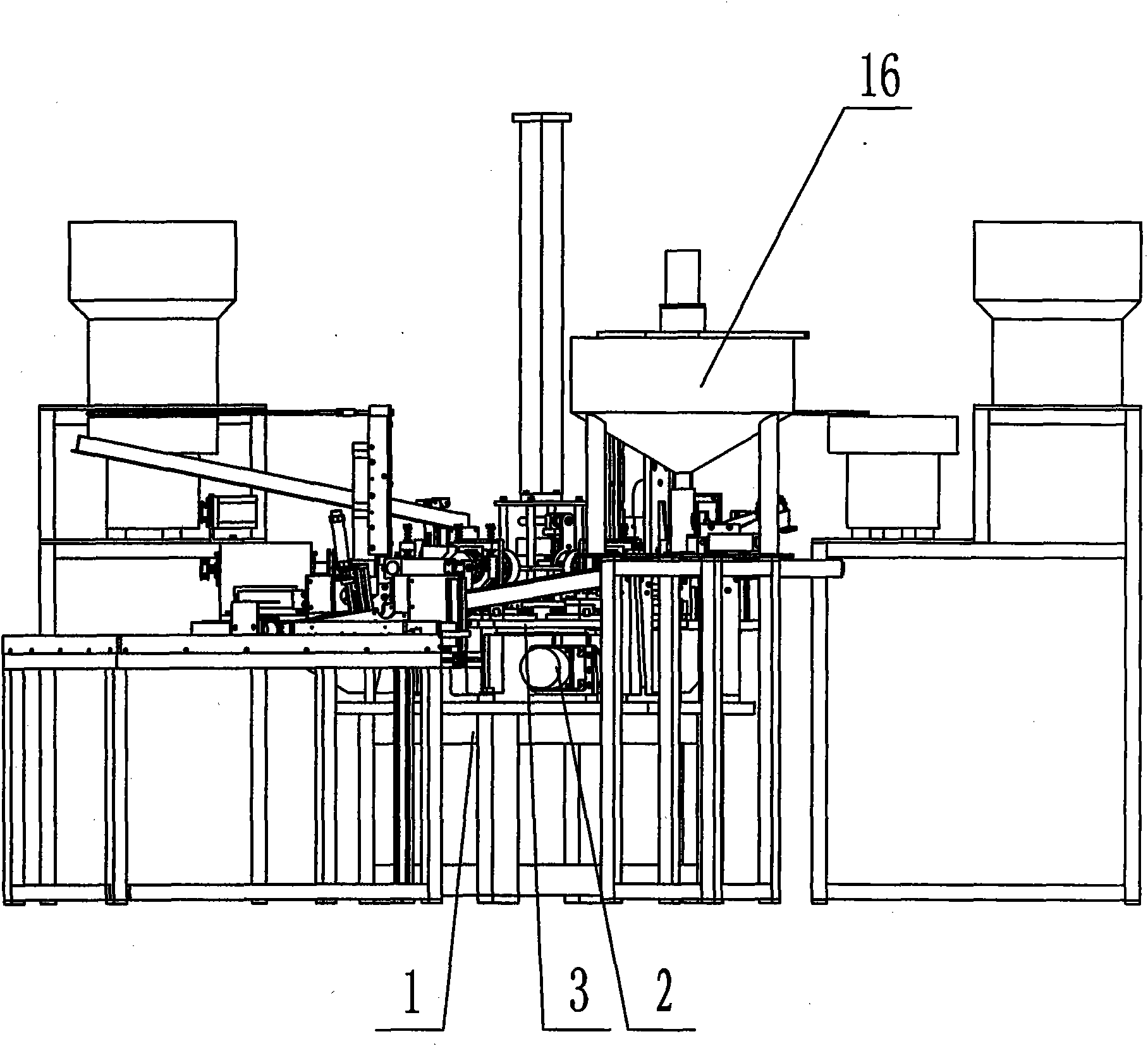

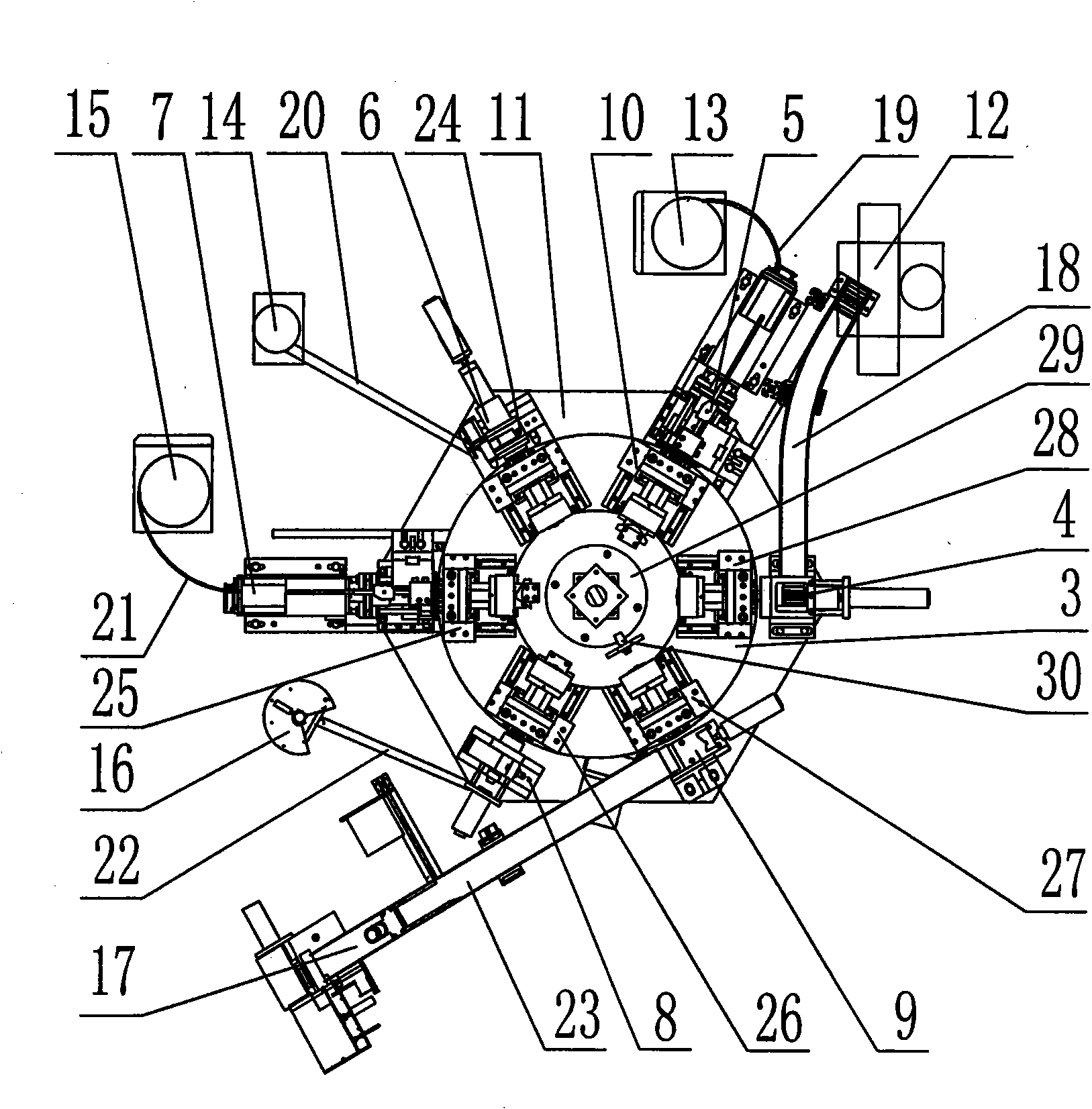

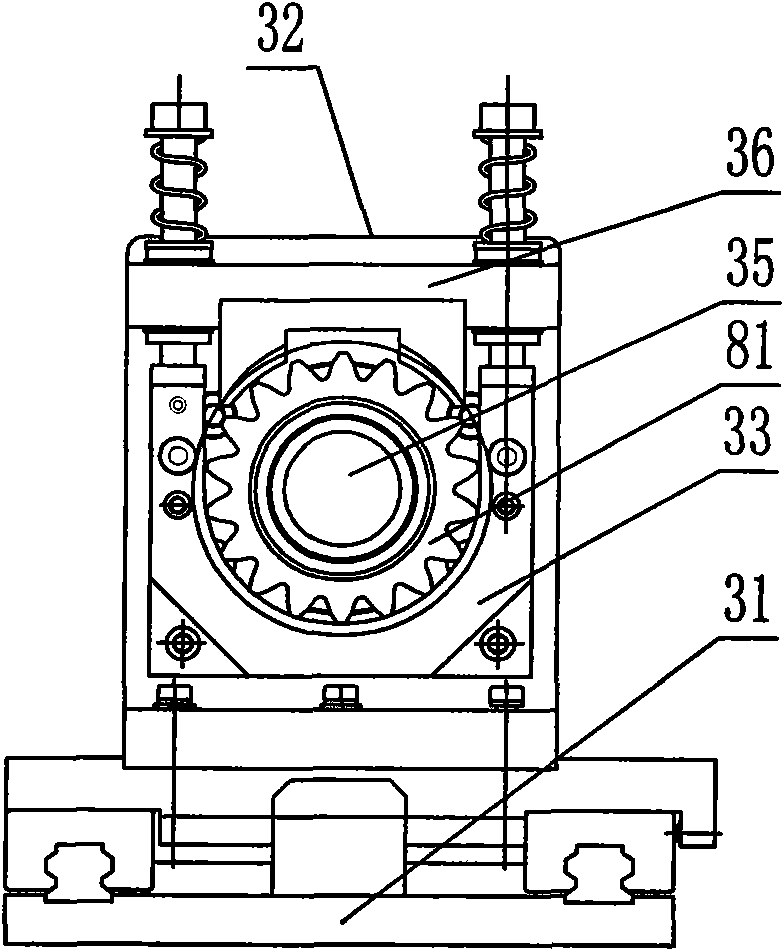

[0031]An automatic needle roller assembly machine for planetary wheels, which consists of a fixed frame 1, a stepping motor 2, an indexing plate 3, a planetary wheel workpiece feeding device 4, a first needle roller feeding device 5, and an annular gasket feeding device 6. The second needle roller feeding device 7, the replacement core part loading device 8, the planetary wheel assembly ejecting device 9, the accompanying fixture A10, the accompanying fixture B24, the accompanying fixture C25, the accompanying fixture D26, the accompanying fixture E27, the accompanying fixture F28 , Planetary wheel workpiece feeding device 12, first needle roller vibration feeding device 13, ring gasket vibration feeding device 14, second needle roller vibration feeding device 15, core replacement feeding device 16 and discharge detection device 17, the upper end of the fixed frame 1 is movably installed with an indexing plate 3, a fixed mounting plate 29 is arranged above the indexing plate 3,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com