Parallelogram connecting rod type automatic clamping bracket

一种平行四边形、自动夹紧的技术,应用在机台/支架、支承机器、机架配置等方向,能够解决结构复杂、制作成本高、耗电等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

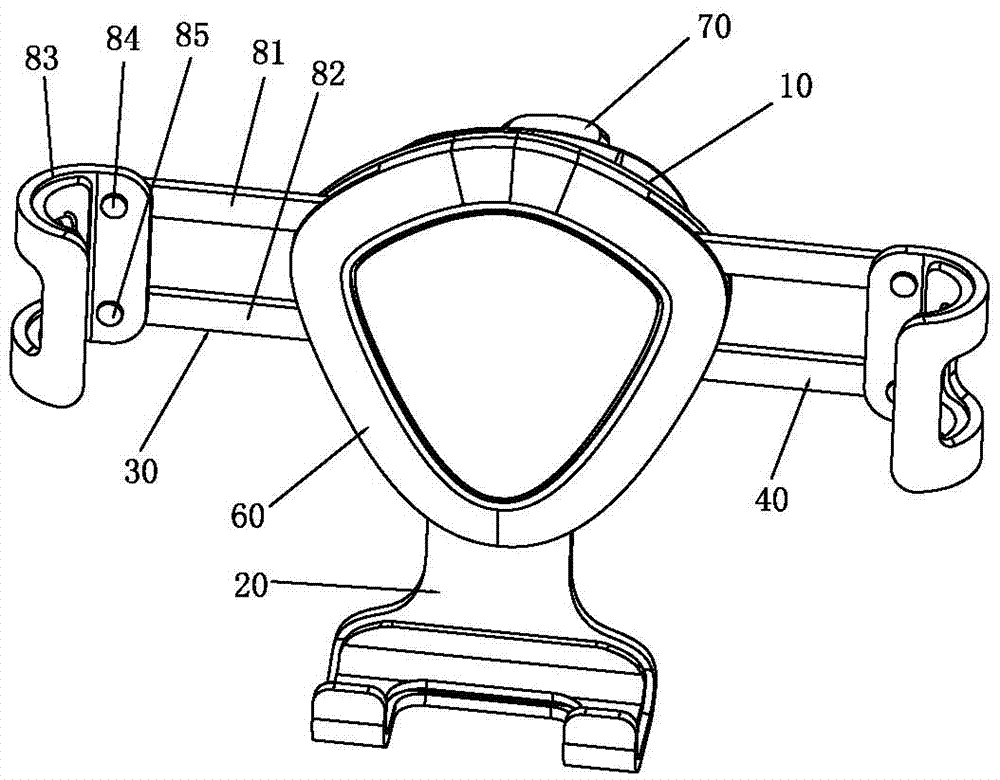

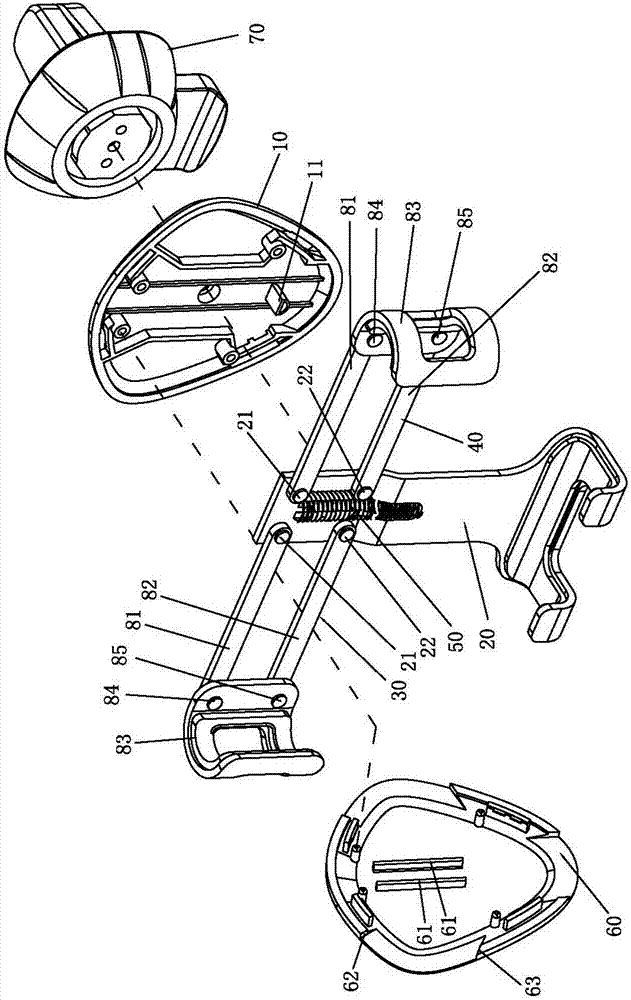

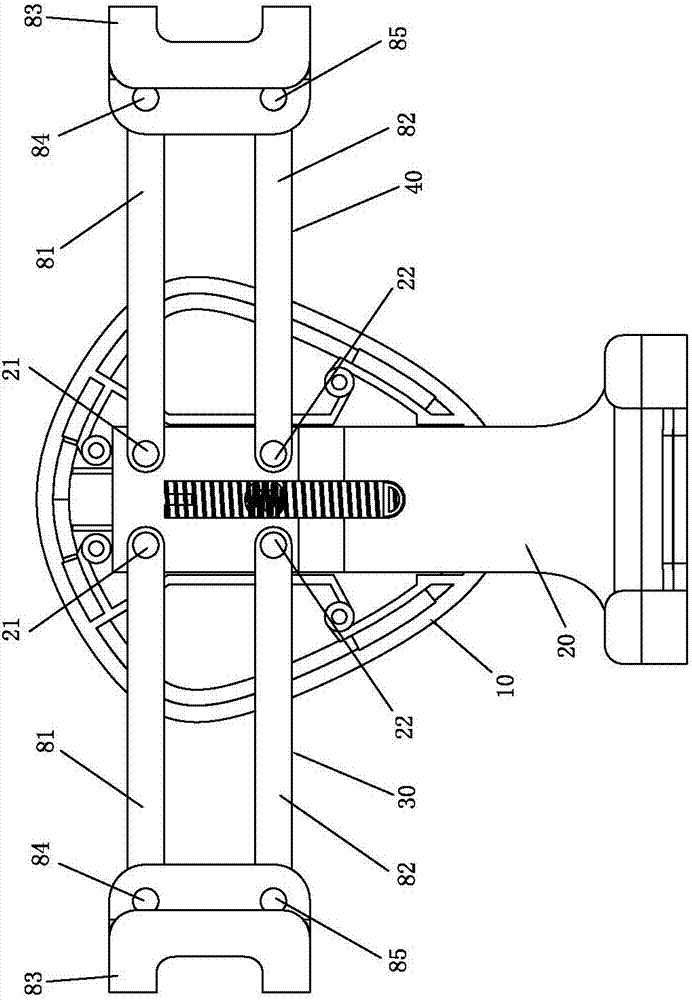

[0032] Please refer to Figure 1 to Figure 3 As shown, it has shown the specific structure of the embodiment of the invention; the said engaging linkage rotary clamping bracket is mainly used in vehicle-mounted applications, of course, it is not limited to vehicle-mounted applications; it mainly includes a rear side base 10 And the bottom support arm 20 , the left clamping arm 30 , the right clamping arm 40 and the reset elastic element 50 installed on the rear base 10 .

[0033] The left clamping arm 30 and the right clamping arm 40 both include a clamping portion 83, a first connecting rod 81, and a second connecting rod 82; the bottom supporting arm 20 is connected with a supporting portion for supporting a mobile device , the bottom support arm 20 is arranged with the first rotation fulcrum 21 and the second rotation fulcrum 22 arranged with the upper and lower spacing for the left clamping arm 30 and the right clamping arm 40; the clamping part 83 is provided with the upp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com