Multi-side milling machine and hydraulic clamp for same

A technology for hydraulic fixtures and milling machines, applied in the field of machine tools, can solve problems such as hidden safety hazards, connection failures, and high labor intensity, and achieve the effects of improving the production environment, improving work efficiency, and improving processing quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with accompanying drawing.

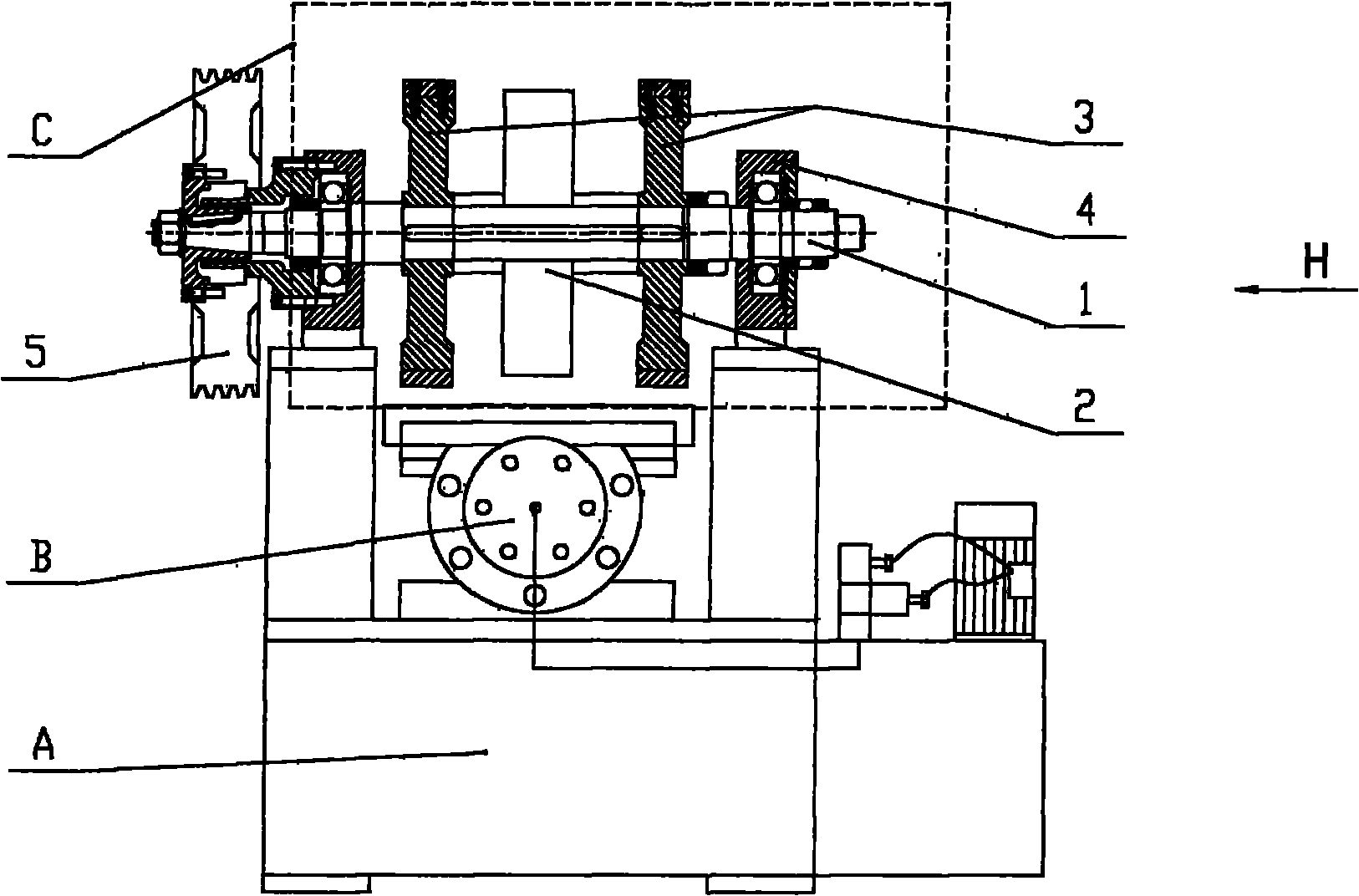

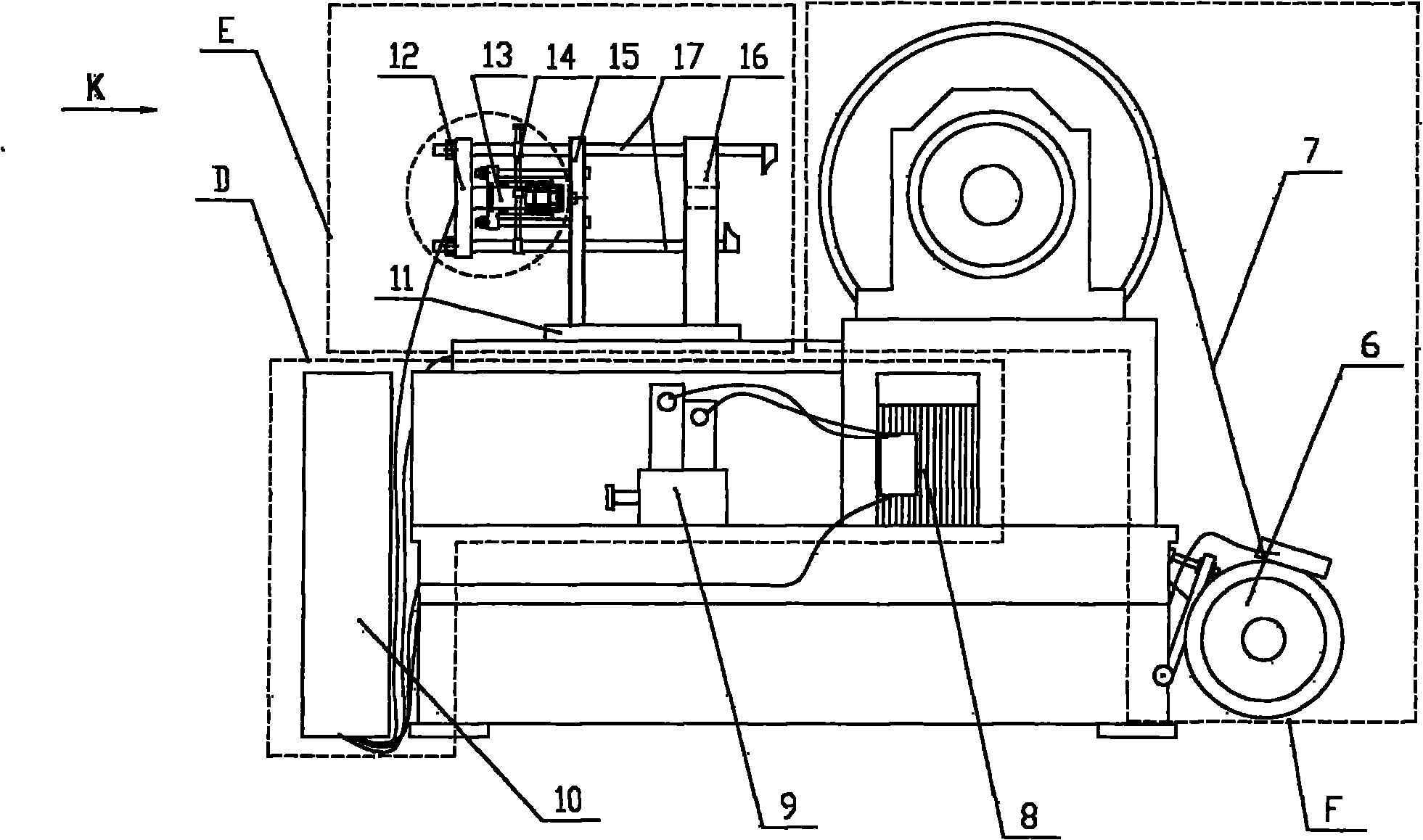

[0023] figure 1 The middle bed A is fixed with a sliding seat and a power head C that cooperate with the hydraulic sliding table B, and the hydraulic sliding table B can move along the vertical direction of the main shaft of the power head C on the sliding seat.

[0024] The driving device F in the dotted line frame is composed of a pulley 5, a motor 6 and a belt 7. Its working principle is: the hydraulic station D controls the operation of the motor 6, and drives the pulley 5 to rotate through the transmission of the belt 7, thereby driving the main shaft of the power head to rotate.

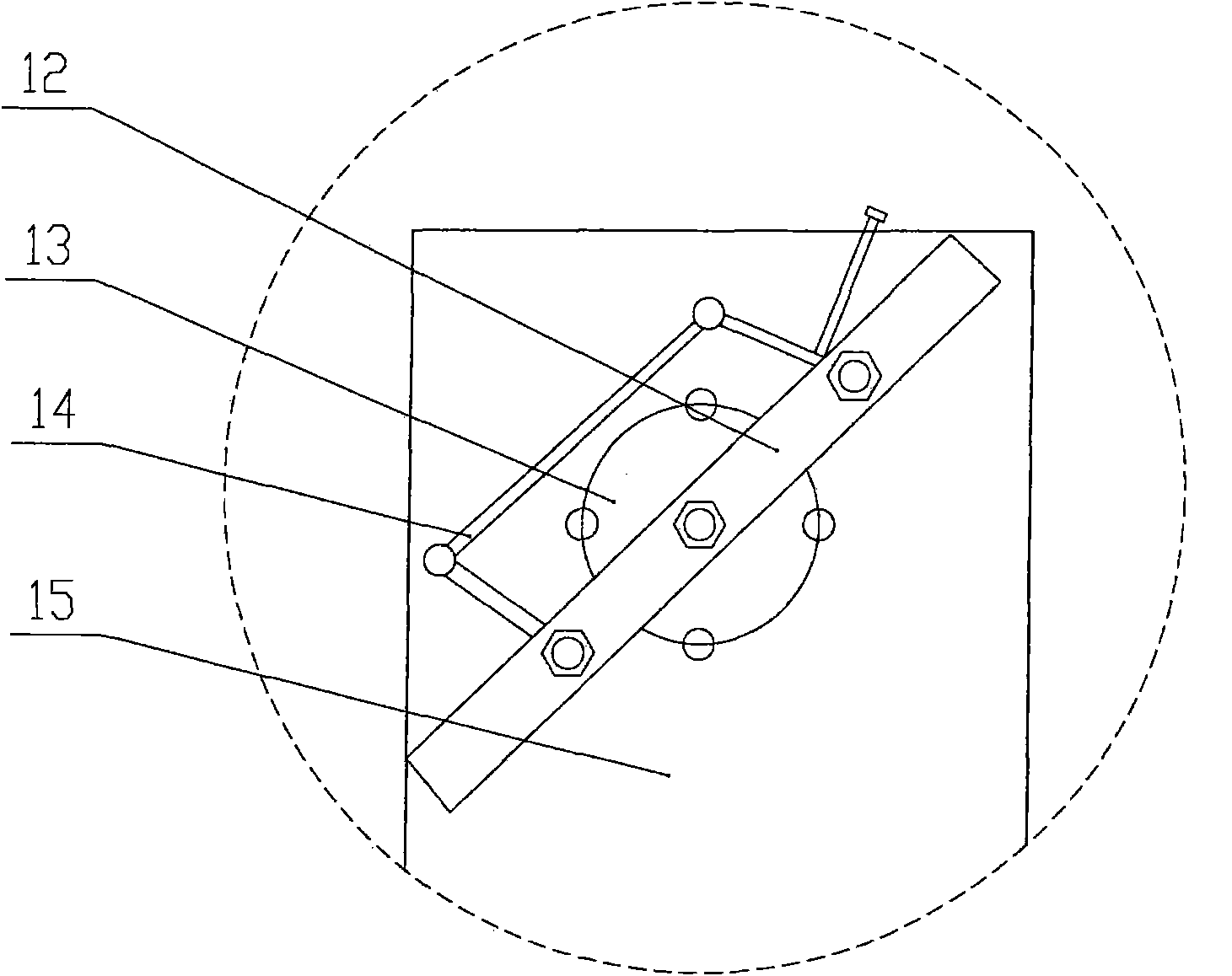

[0025] The power head C in the dotted line box is composed of a main shaft 1, a three-sided milling cutter disc 2, two milling cutter discs 3 and a bearing seat 4. The three-sided milling cutter disc 2 is located in the middle of the main shaft, and two milling cutter discs 3 are located at ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com