Chopping board side wall grooving equipment

A technology for grooving equipment and cutting boards, which is used in metal processing equipment, metal processing machinery parts, maintenance and safety accessories, etc., can solve the problems of time-consuming and labor-intensive, and it is difficult to always keep the cutting machine attached to the side wall of the cutting board.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

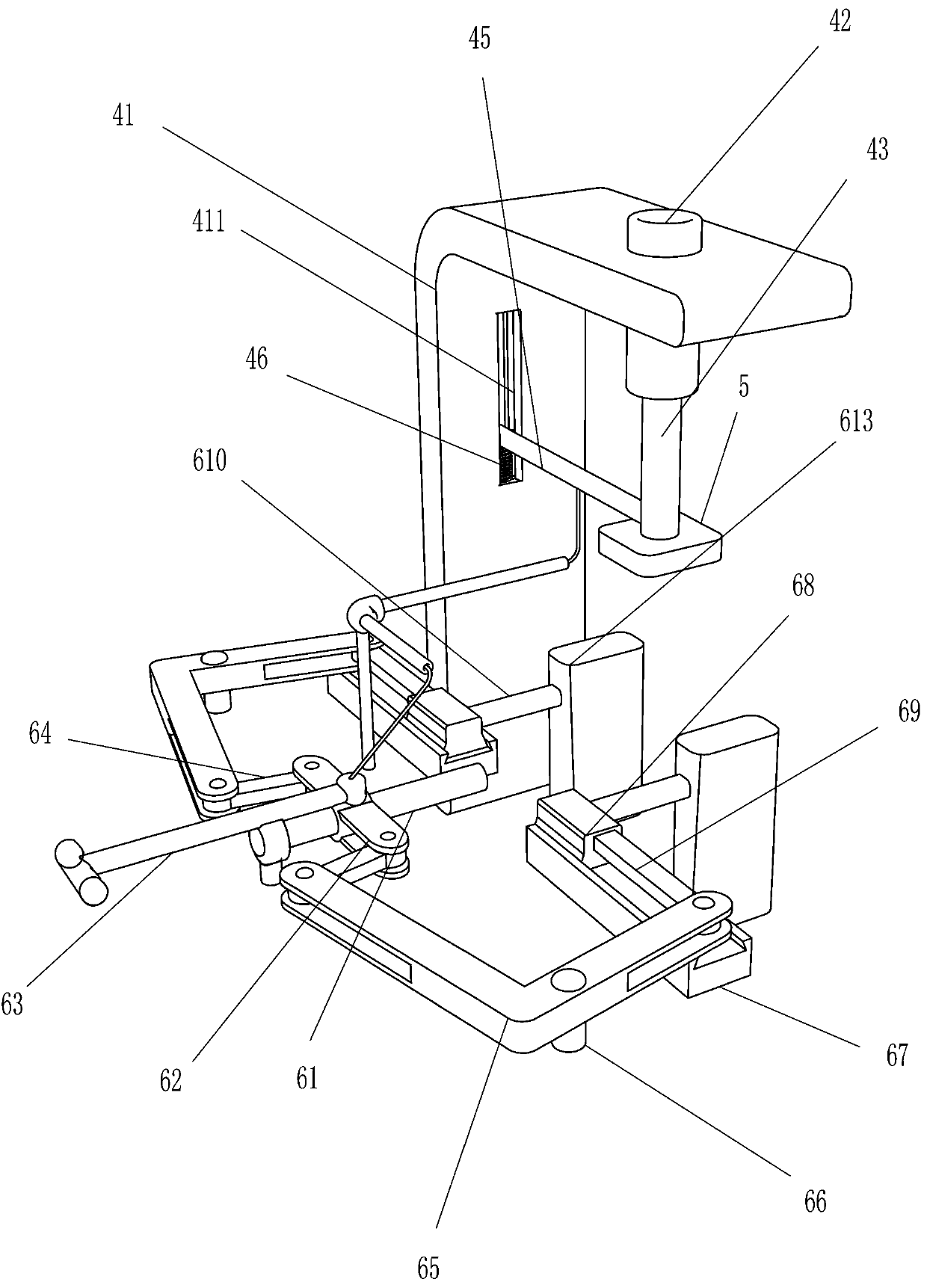

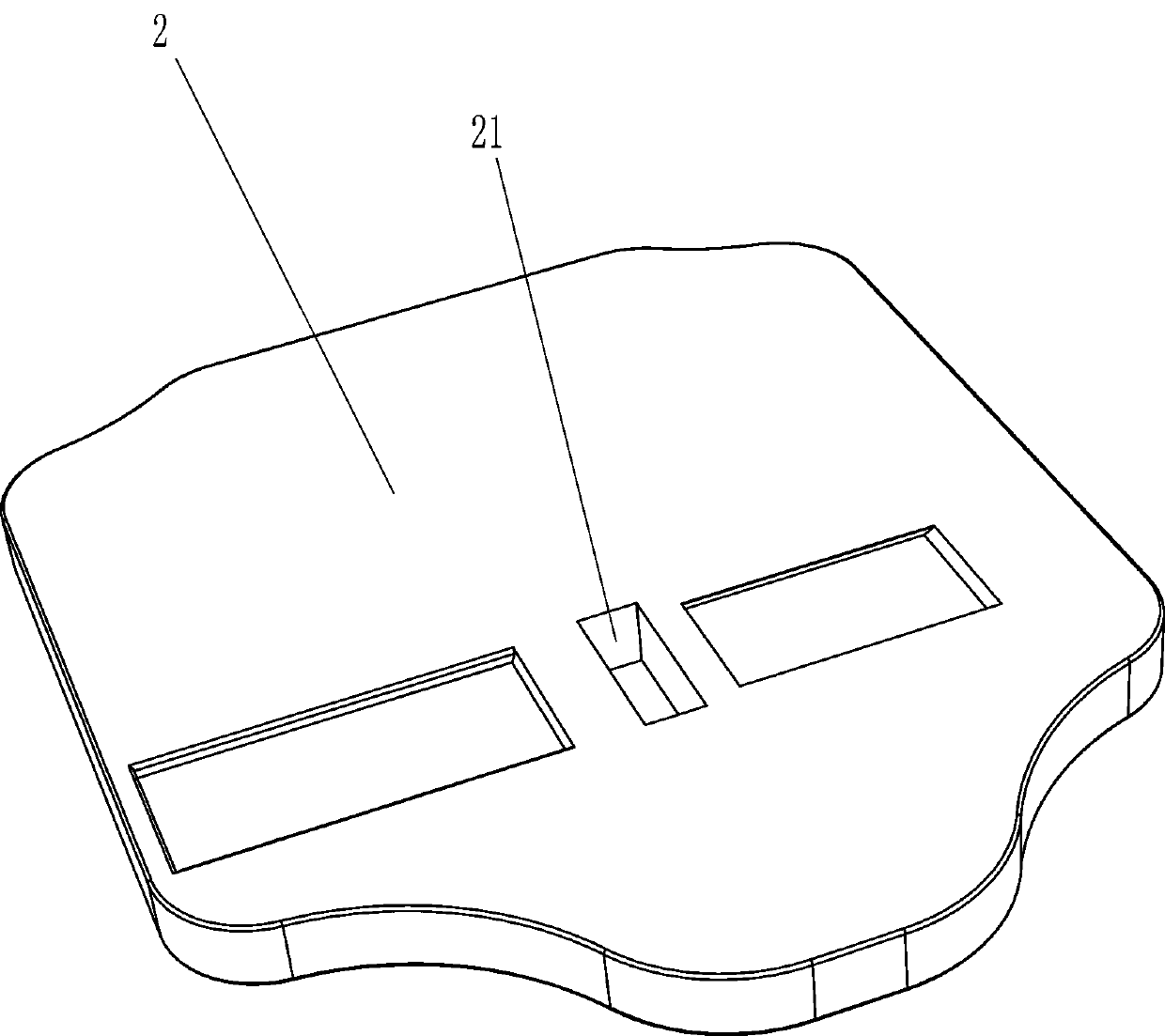

[0053] A cutting board side wall slotting device, such as figure 1 with Image 6 As shown, a cutting board side wall slotting equipment includes a base, a workbench, a cylindrical storage box, a lifting mechanism, a cutting machine, a clamping and rotating mechanism, a collection frame, an installation sleeve, a wire tube and a pull wire, and the base is equipped with Workbench, there is a groove in the middle of the right side of the workbench, and a cylindrical storage box is provided in the middle of the right side of the workbench. There are round holes on both sides of the cylindrical storage box. The cylindrical storage box is located directly above the groove. There is a lifting mechanism at the rear of the side, and a cutting machine is installed at the lower end of the front side of the lifting mechanism. The cutting machine is located directly above the cylindrical storage box, and the top of the workbench is equipped with a clamping and rotating mechanism. The hole...

Embodiment 2

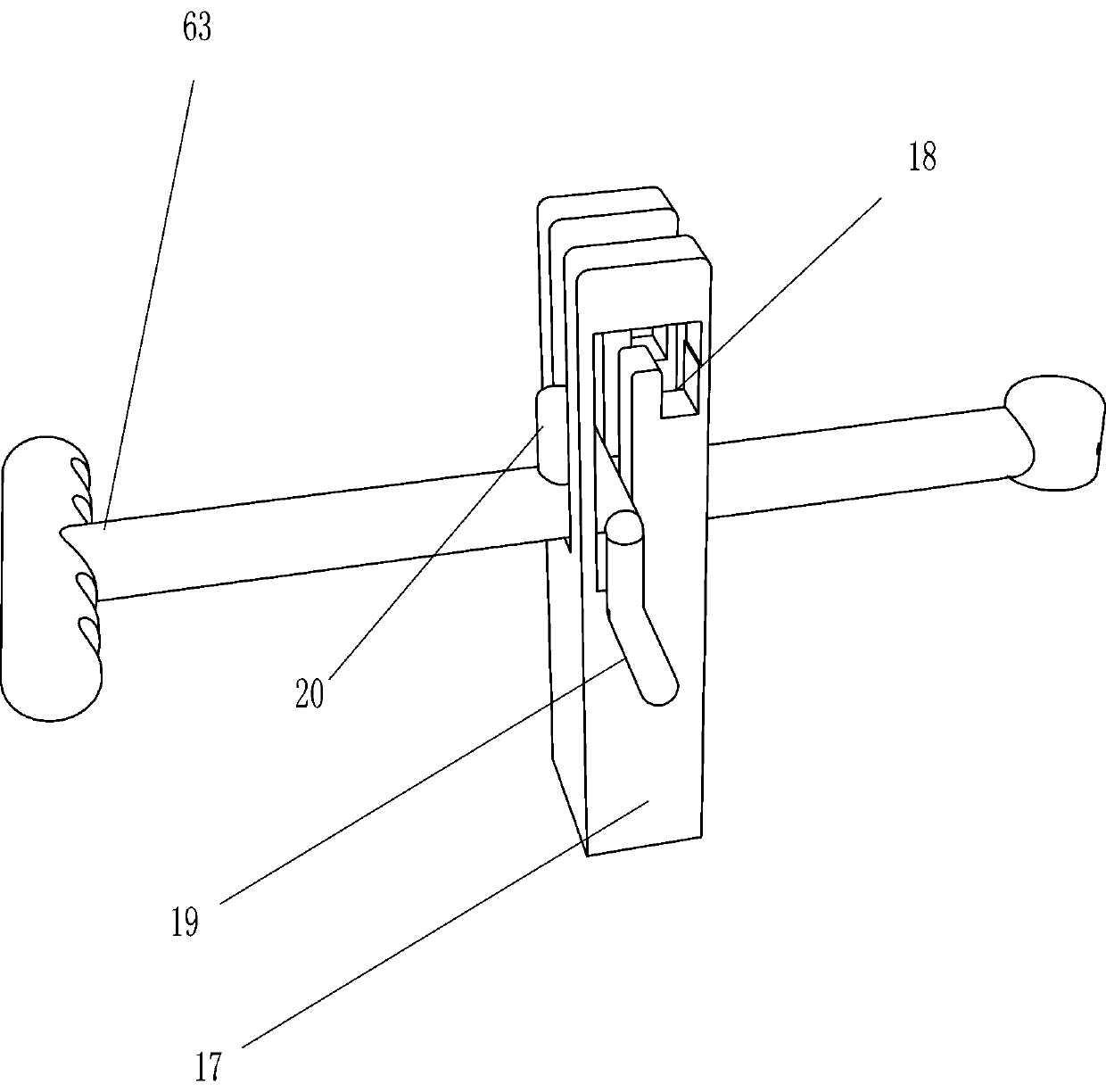

[0056] A cutting board side wall slotting device, such as Figure 1-2 with Figure 5 As shown, preferably, the lifting mechanism includes an L-shaped frame, a cylindrical sleeve, a cylindrical rod, a first spring, a first connecting rod, and a second spring. There is a square groove, a cylindrical sleeve is provided on the top of the L-shaped frame, and a cylindrical rod is provided slidingly at the bottom of the cylindrical sleeve. A first spring is connected between the inner bottom of the cylindrical sleeve and the top of the cylindrical rod, and the cylindrical rod passes through the second spring. A spring, a first connecting rod is arranged between the bottom of the cylindrical rod and the square groove, the rear end of the first connecting rod is slidingly matched with the square groove, and a second spring is arranged between the rear end of the first connecting rod and the bottom of the square groove.

[0057] After starting the clamping and rotating mechanism, the c...

Embodiment 3

[0059] A cutting board side wall slotting device, such as Figure 1-4 As shown, the clamping and rotating mechanism includes guide rods, sliding rods, pull rods, first connecting rods, L-shaped rods, first rotating shafts, slide rails, sliders, second connecting rods, second connecting rods, sliding blocks, installation Plate, rotating shaft, circular splint, motor, fixed frame, clamping rod and round rod. There is a fixed frame in the middle of the left side of the top of the workbench. There is a guide rod between the middle part of the side and the left side of the cylindrical storage box. The guide rod is located on the right side of the fixed frame. The upper part of the guide rod is slidingly equipped with a pull rod. Located on the left side of the clamping rod, the top of the right end of the pull rod is connected to the left end of the pull wire. There are slide bars on both sides of the right end of the pull rod. The rotating type is equipped with L-shaped rods, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com