Blanking and loading mechanism of full-automatic diamond lapping and polishing machine and fixture switching mechanism thereof

A fully automatic, fixture technology, applied to grinding/polishing equipment, machine tools suitable for grinding the edge of workpieces, grinding machines, etc., can solve the problem of inability to realize fully automatic generation of diamond grinding and polishing machines, reduced processing efficiency, and extended process time and other problems to achieve the effect of saving fixture transmission time, improving work efficiency and reliable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

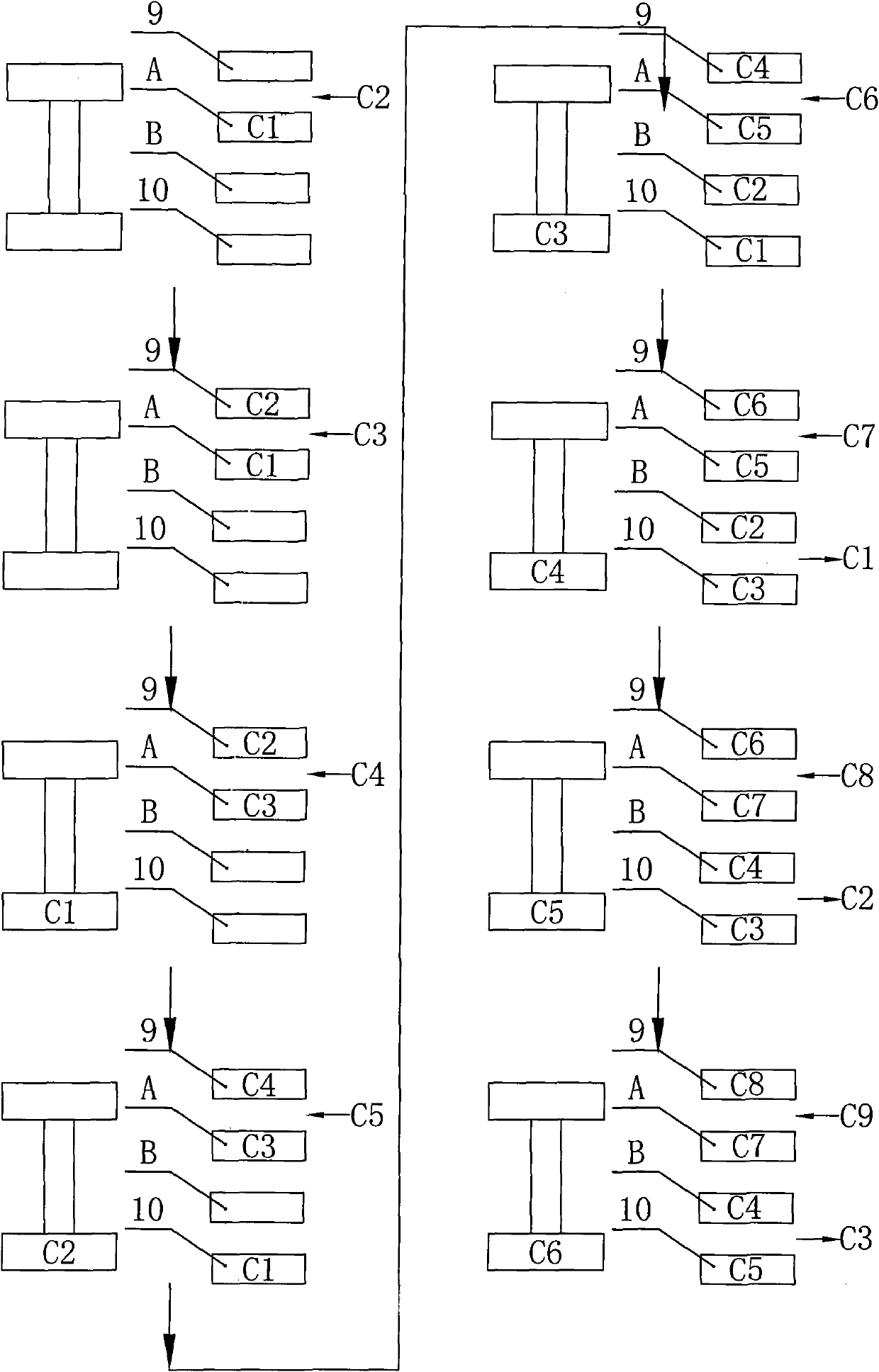

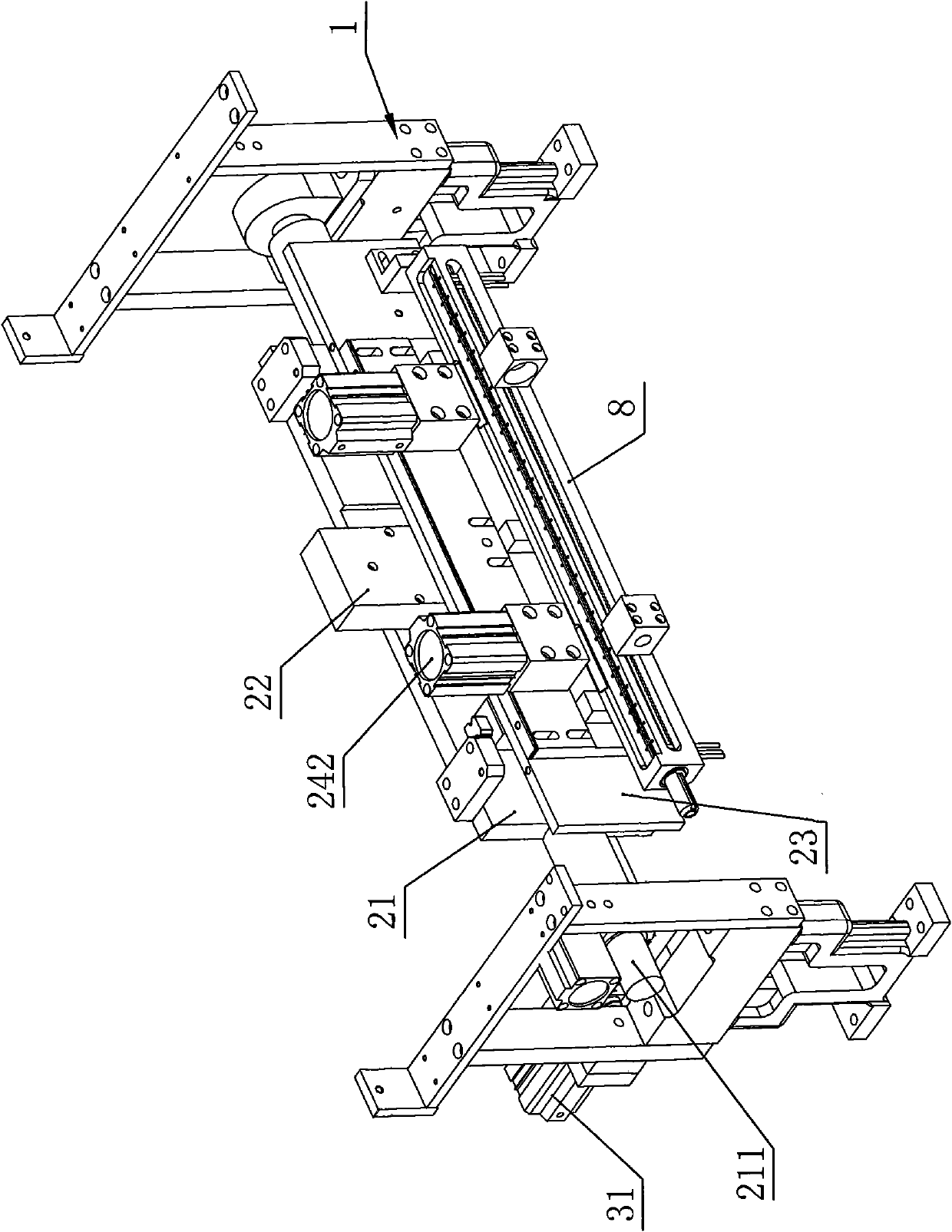

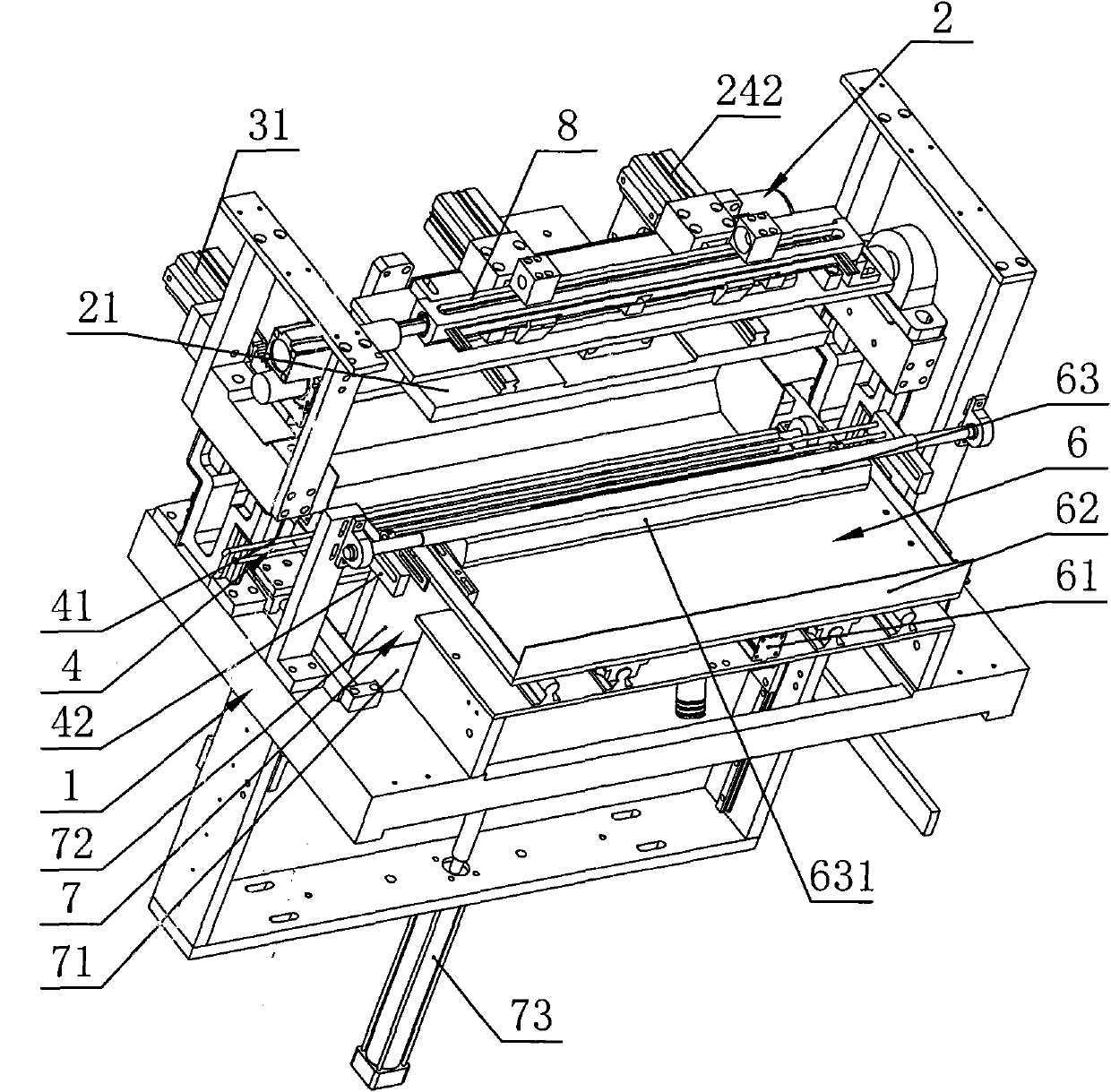

[0023] like figure 1 one Figure 7 As shown, a fully automatic diamond grinding and polishing machine's lowering, loading and clamp conversion unit includes a bracket 1, and two groups of lowering and loading devices A and B are symmetrically arranged on the bracket 1, and are arranged on two groups of lower, The clamp conversion device 8 on the same side of the feeding device A and B, wherein each group of lower and upper feeding devices A and B are respectively provided with baffles 9 and 10, and the baffles 9 and 10 are slidably arranged on the support 1. The purpose of having baffles 9 and 10 is: the time to complete both the unloading process and the loading process in this fully automatic diamond grinding and polishing machine is about twice the time of the two transfer intervals of the fixture, so the loading and unloading device After A and B have worked for half the time, the fixture C sent from the previous process can be placed on the baffle 9 or 10 first, so that ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com