Punch press die holder with hand-operated retaining clamp

a technology of retaining clamp and punch press, which is applied in the field of punch press die holder, can solve the problems of inapplicable circular die methods, inability to manually remove or replace circular dies that are in wide-scale commercial use, and laborious and time-consuming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

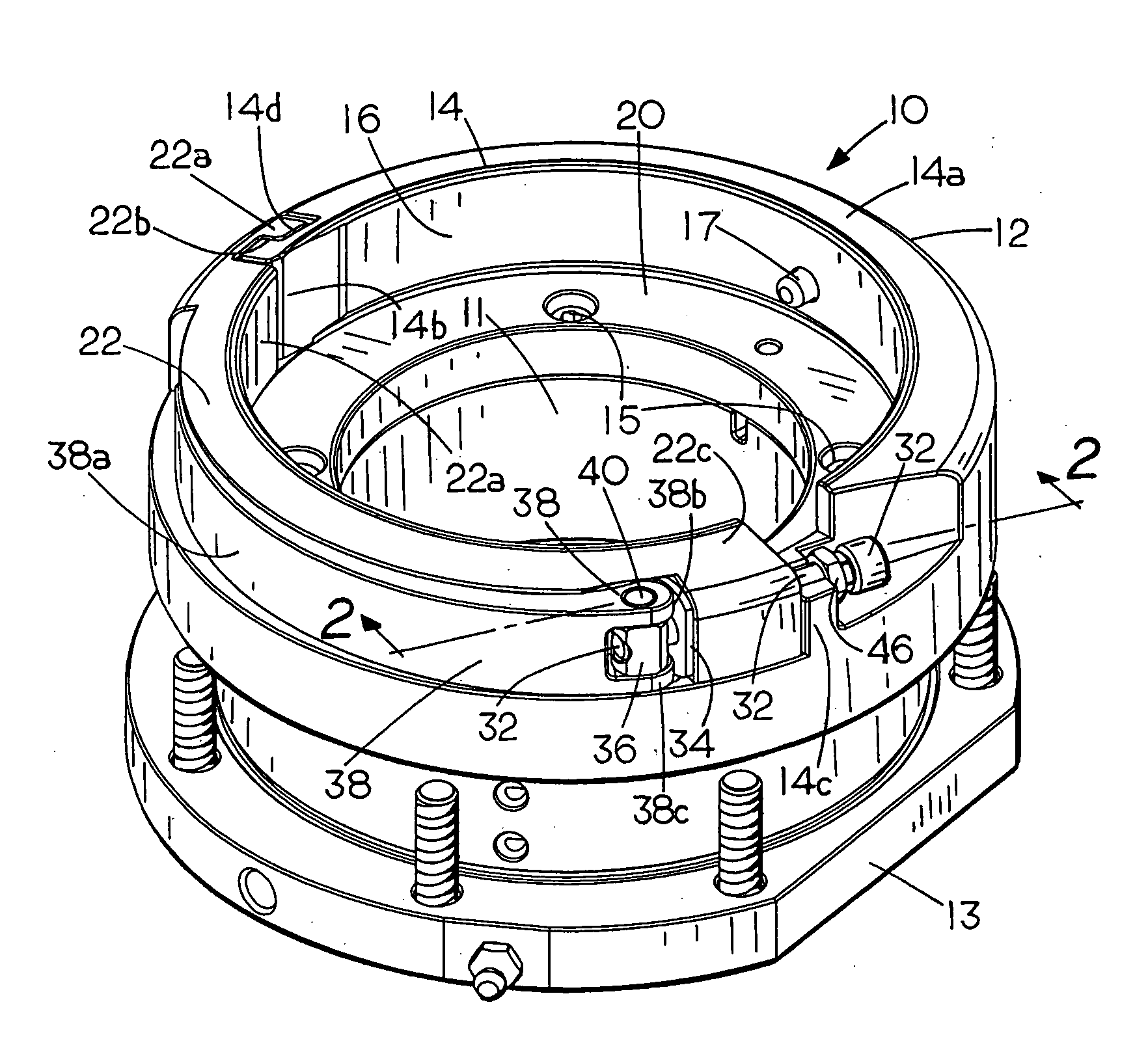

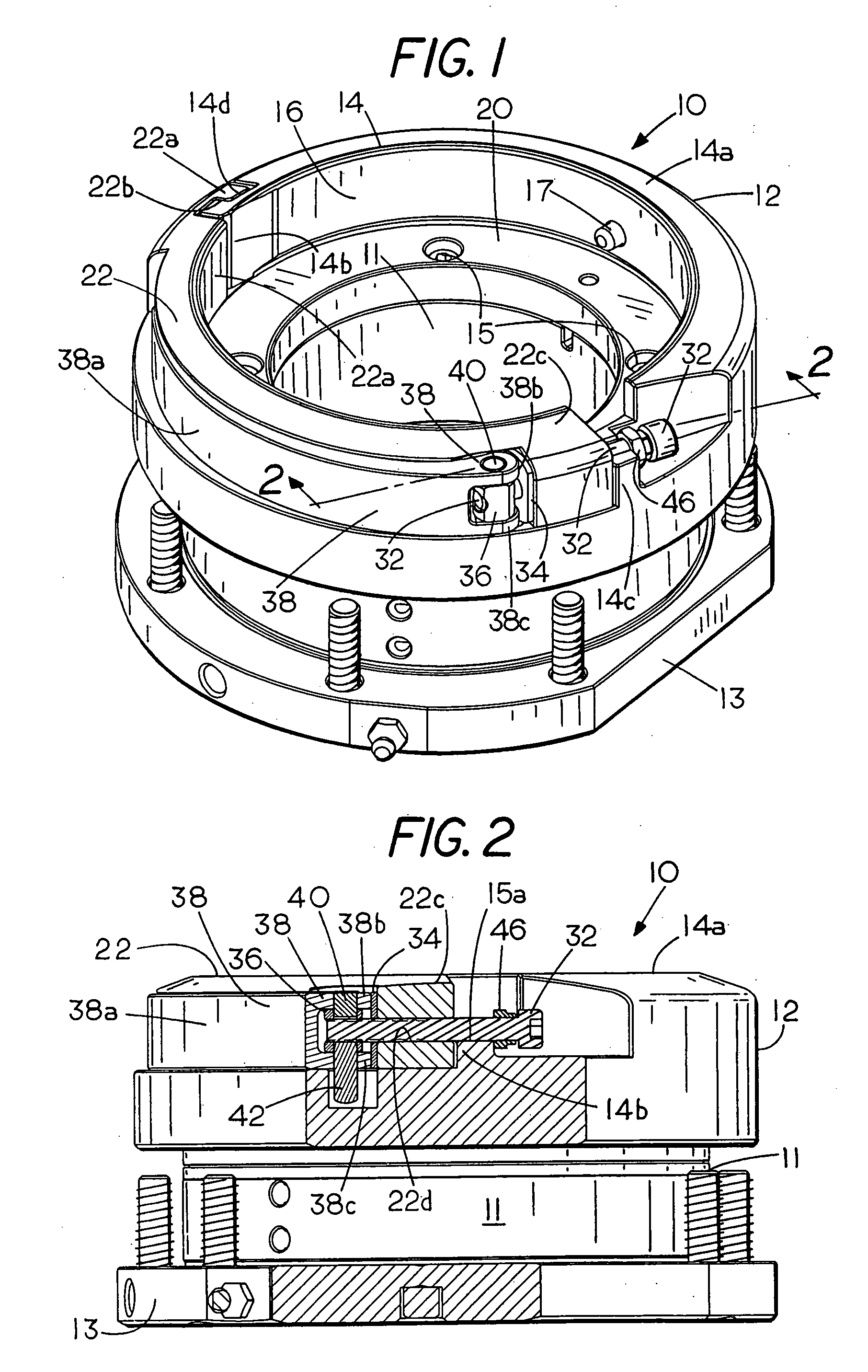

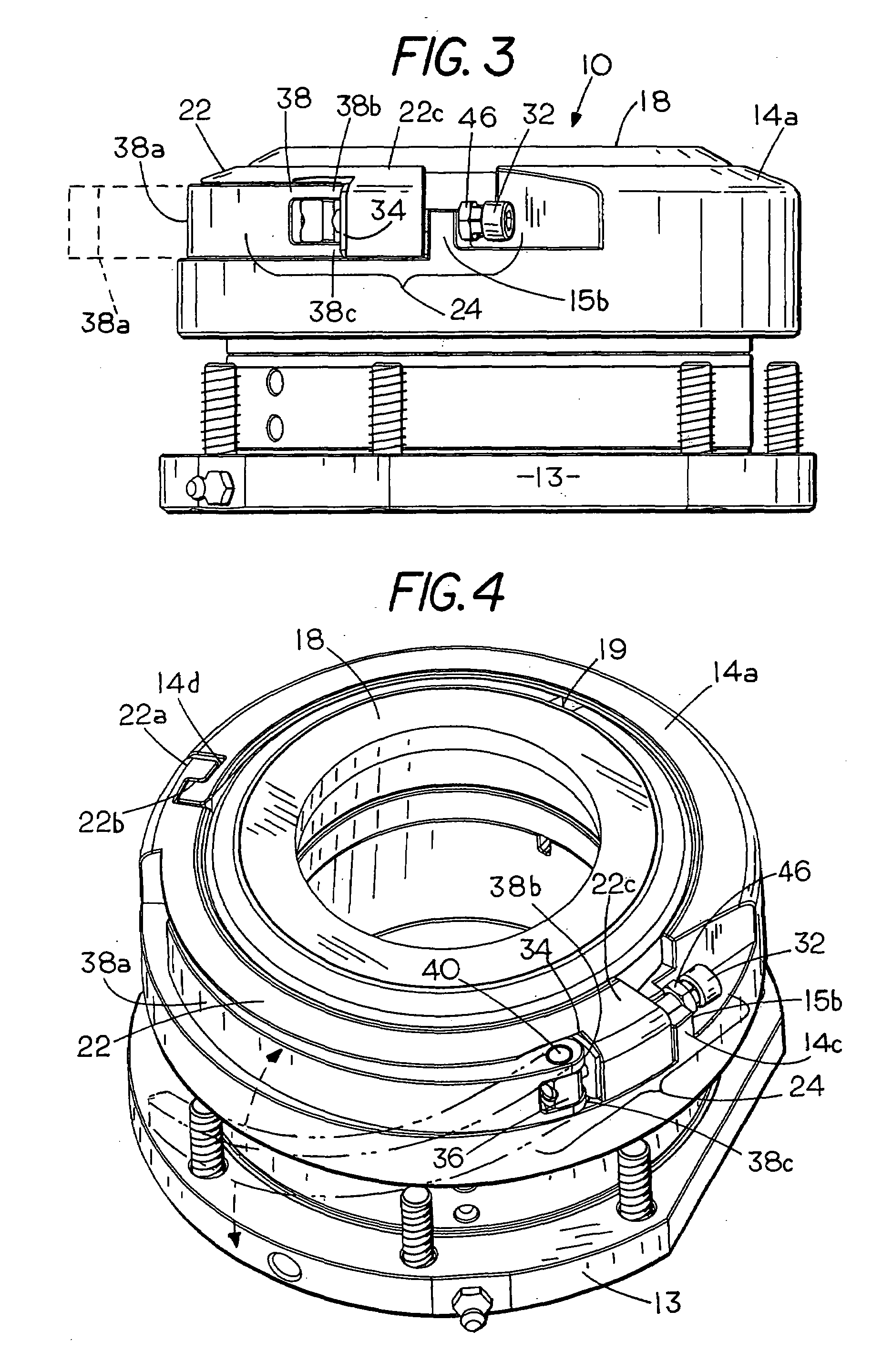

[0023]Refer now to the Figs., and particularly to FIGS. 1-4 which show a punch press die holder assembly 10 having an annular die holder body 12 with a circular rim 14 surrounding a generally cylindrical die receptacle or die socket 16. The die holder 10 is mounted on the punch press (not shown) in any suitable manner, e.g. using a base plate 13 of conventional well-known construction. The die holder 10 has a downwardly extending inner sleeve 11 of conventional construction that is journaled for rotation in the base plate 13. Sleeve 11 can be secured to the lower portion of receptacle 16 by fasteners such as cap screws 15 (FIG. 1). The receptacle 16 is dimensioned to receive the circular punch press die 18 (FIG. 4). At the bottom of the receptacle 16 of the die holder assembly 10 is a circular die-supporting surface 20 (FIGS. 1 and 7) for limiting the downward movement of a die 18 when the die is mounted for operation within the receptacle 16 as shown in FIG. 4. Receptacle 16 has a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| pressure | aaaaa | aaaaa |

| time | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com