Multi-station punching machine

A multi-station, punching machine technology, applied in the field of punching machines, can solve the problems of poor product quality stability, many stamping processes, and high processing costs, and achieve the effects of saving stamping die replacement time, improving precision and efficiency, and improving stamping accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

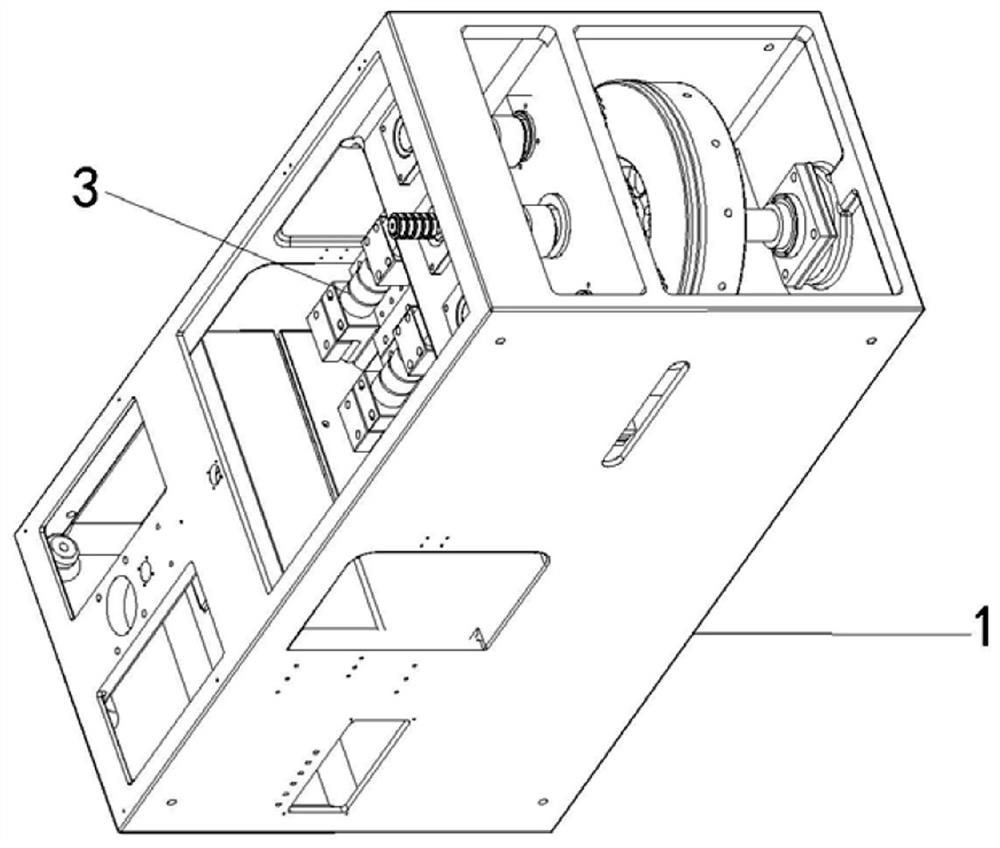

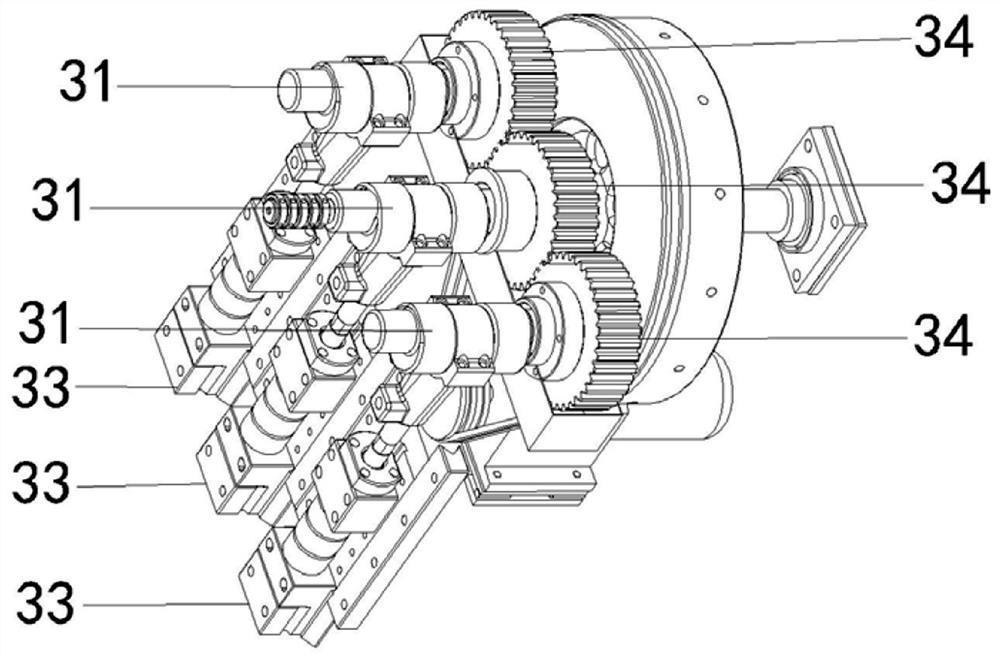

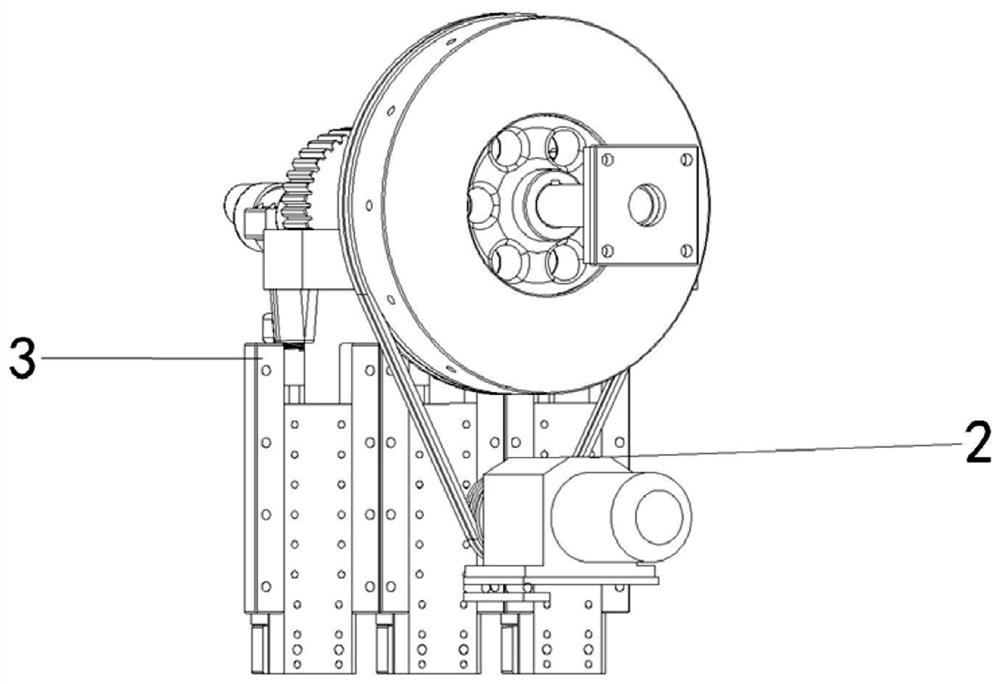

[0019] see Figure 1-5 As shown, the present invention relates to a multi-station punch press, including a punch frame 1, a power input mechanism 2 and several power output mechanisms 3, and the power output mechanisms 3 can be two ( Figure 6 ), which can be three ( image 3 ), the punch frame 1 is provided with a workbench, and the workbench is provided with a movable lower die, and the power output mechanism 3 is connected to the stamping mechanism 3, that is, an independent power source drives a separate stamping mechanism, avoiding the traditional one power Driving a plurality of stamping dies will cause errors due to mold repairing. This embodiment takes three stamping mechanisms as an example. The three stamping mechanisms are arranged on the punch frame 1 and are driven by gears 34. The power input mechanism 2 and stamping The mechanisms 3 are connected by transmission, and the three stamping mechanisms 3 are respectively connected with an upper die, and a punch is ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com