Intelligent multifunctional independent type wired mechanical hand

An independent, multi-functional technology, applied in the field of manipulators, can solve the hidden dangers of labor safety production, increase the floor space and production cost, adjust the production rhythm, etc. reasonable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

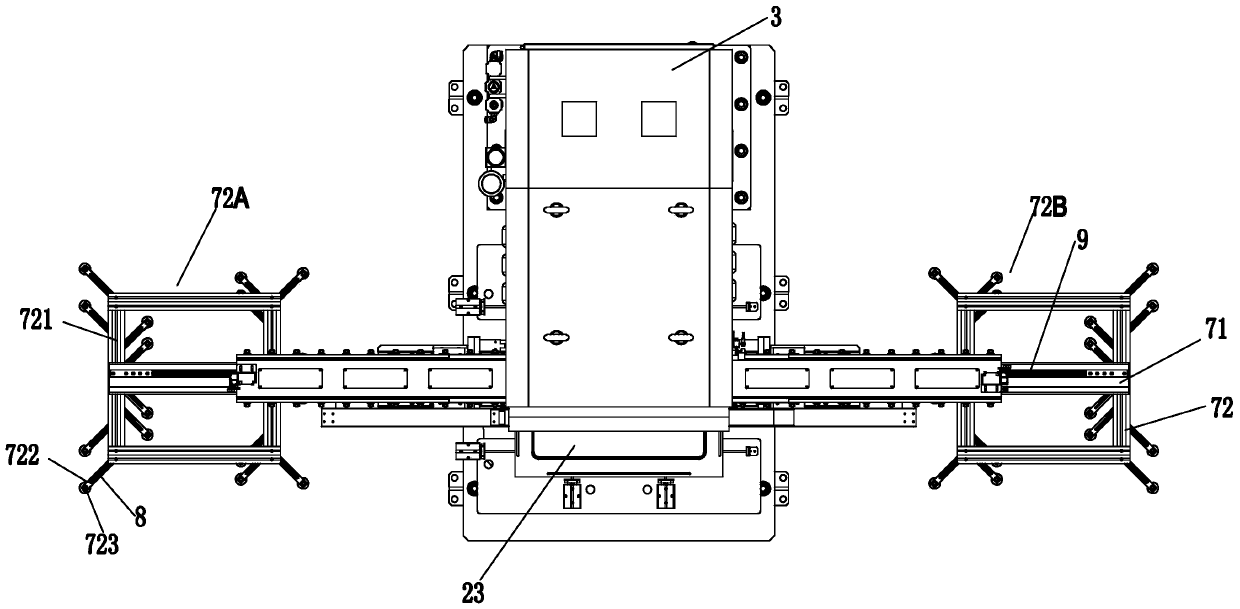

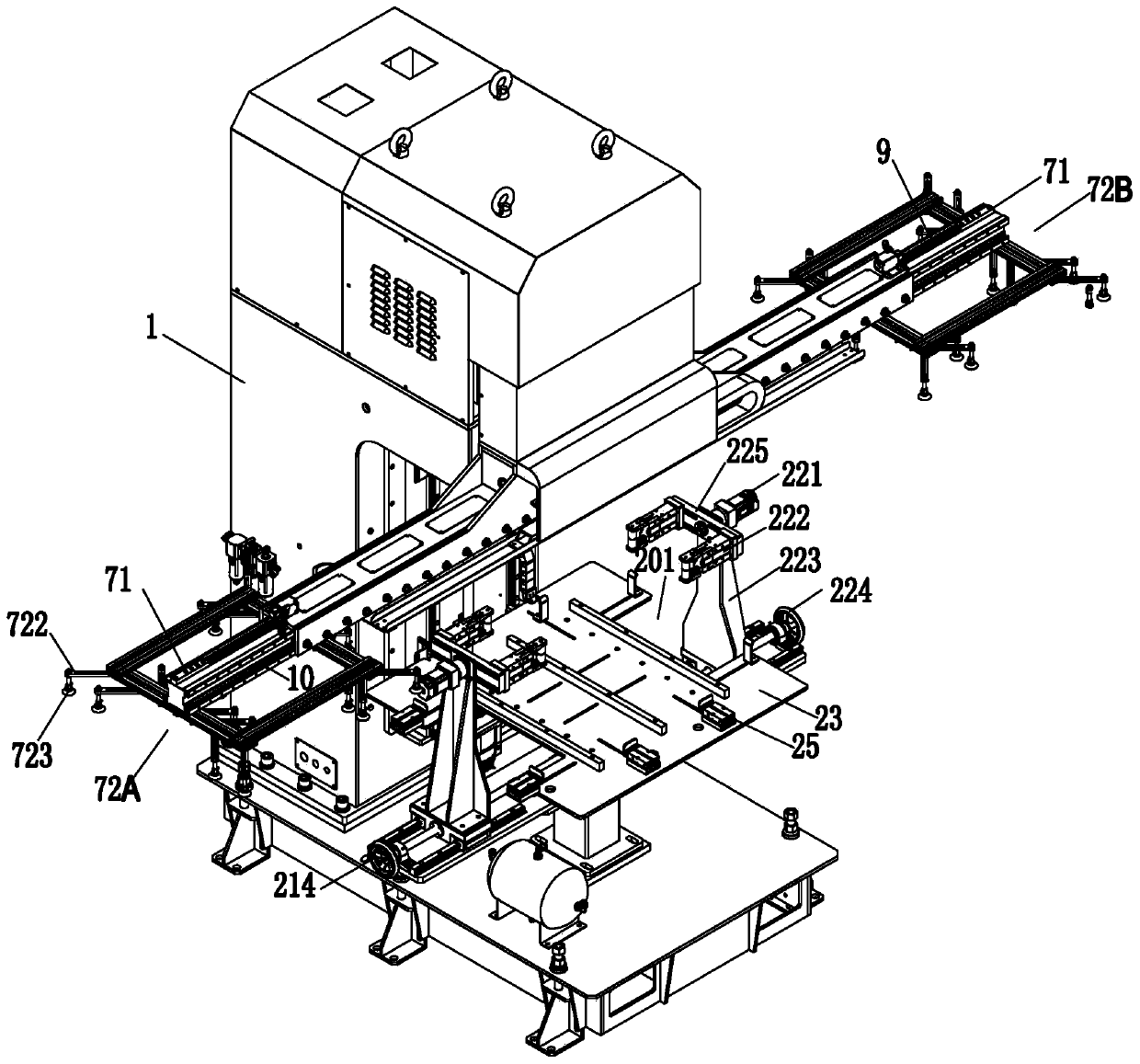

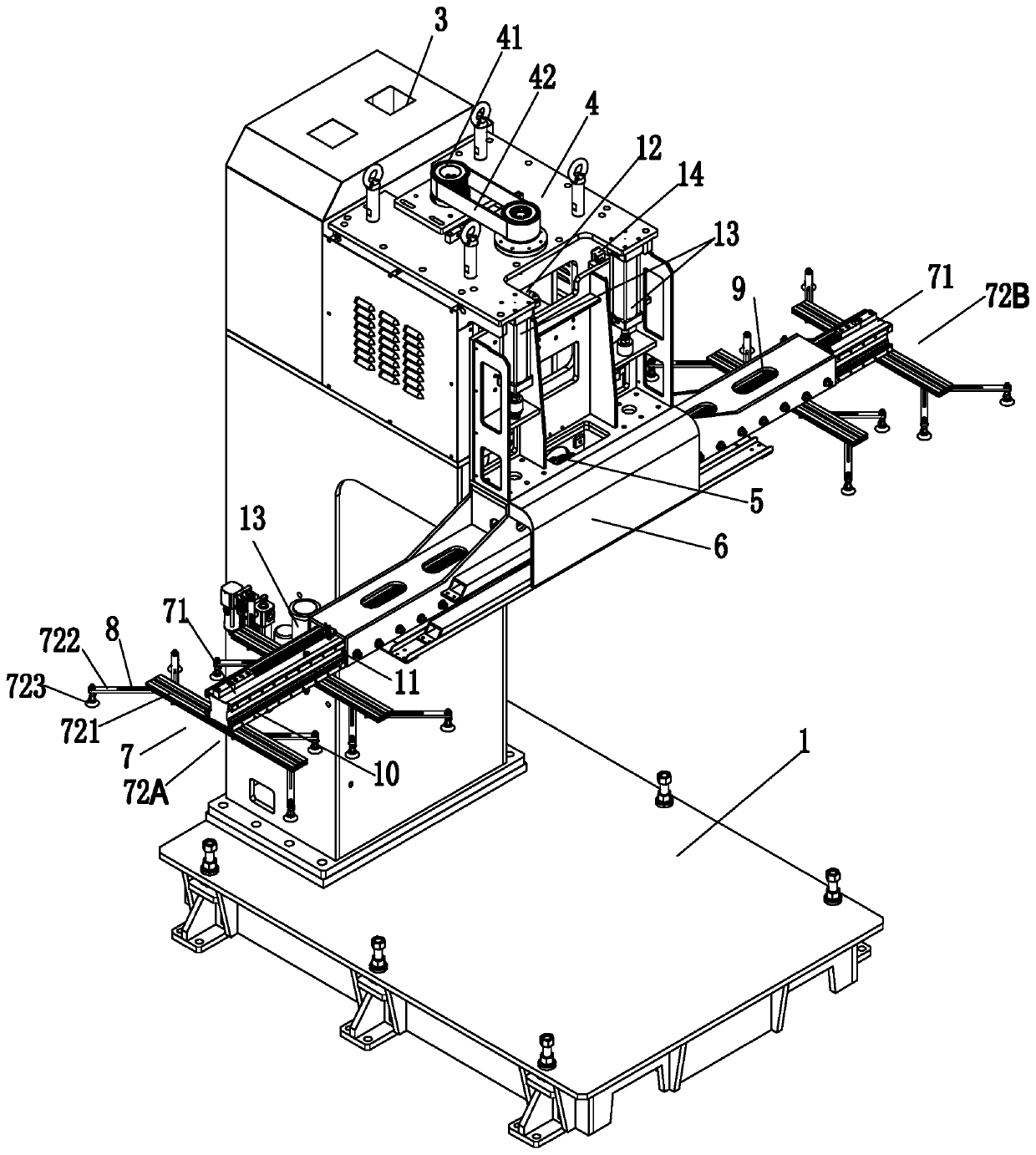

[0033] See Figure 1 to Figure 7As shown, an intelligent multi-functional stand-alone connecting manipulator for serial stamping equipment, including machine base 1, lifting transfer table 2, electric control box 3, lifting mechanism 4, horizontal transfer mechanism 5, connecting seat 6, mechanical arm 7. The lifting transfer table 23, the transfer table lifting mechanism, the left workpiece turning mechanism 21 and the right workpiece turning mechanism 22, the electric control box 3 electrically controls the electric control accessories, and the connecting seat 6 is installed on the machine base 1 through the lifting mechanism 4 , the mechanical arm 7 is arranged on the connection seat 6 through the horizontal transfer mechanism 5, the mechanical arm 7 includes a horizontal transfer guide rail 71 and at least two groups of suction arms 72A, 72B, the ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com