Multi-station flexible stamping workstation

A workstation and multi-station technology, applied in the field of mechanical processing, can solve the problems of complicated and long-time mold conversion process, difficult to control the quality of stamping products, large and complex equipment, etc., to achieve strong product specifications universality, easy production management, Reduce the effect of manual operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

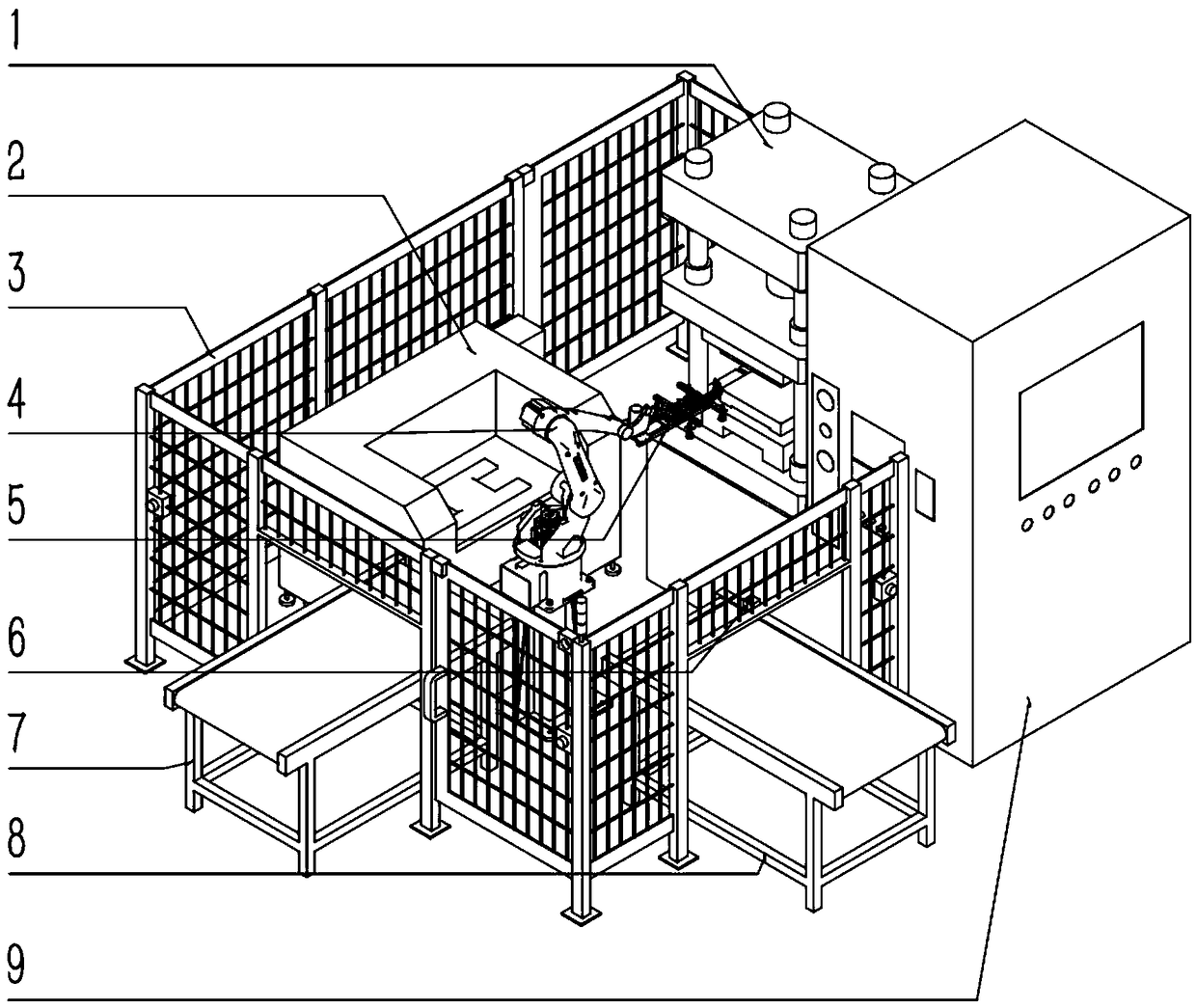

[0024] Such as figure 1 As shown, a multi-station flexible stamping workstation includes a punch (1), a laser cutting machine (2), a safety fence (3), a multi-joint industrial robot (4), a robot gripper (5), and a vision camera (6). ), the discharge conveyor line (7), the input conveyor line (8), and the stamping die library (9).

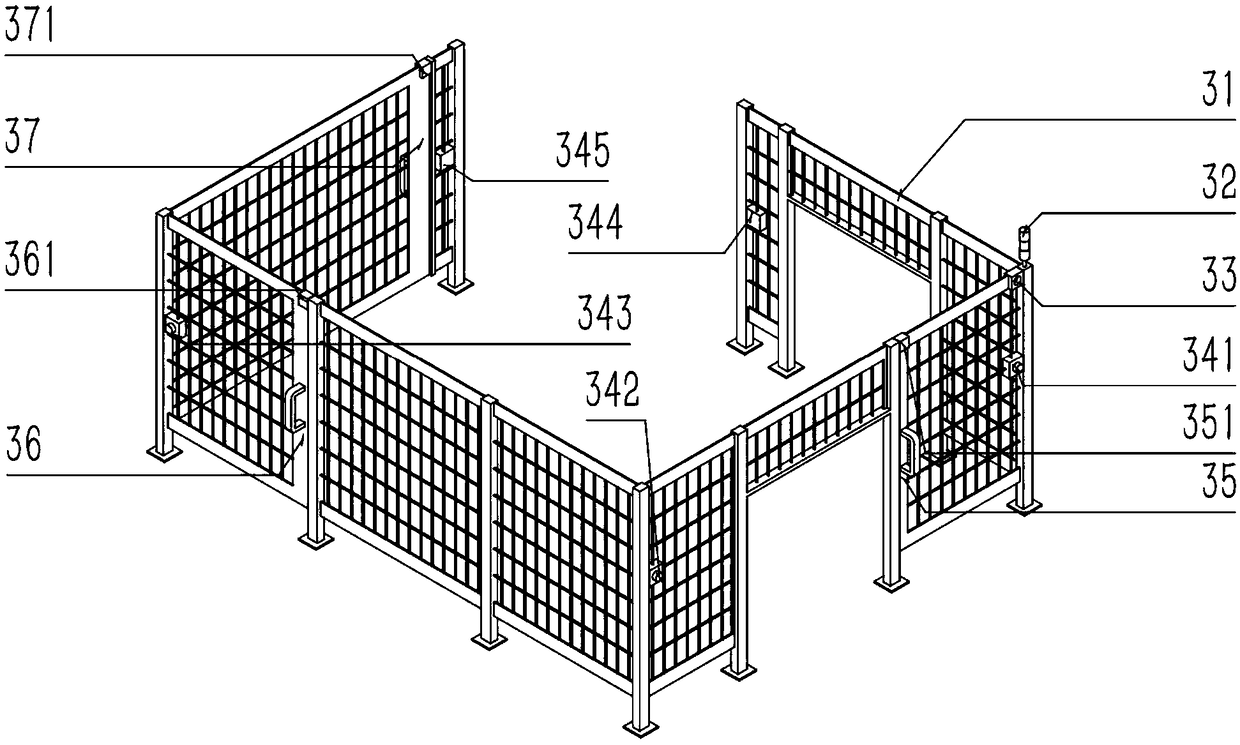

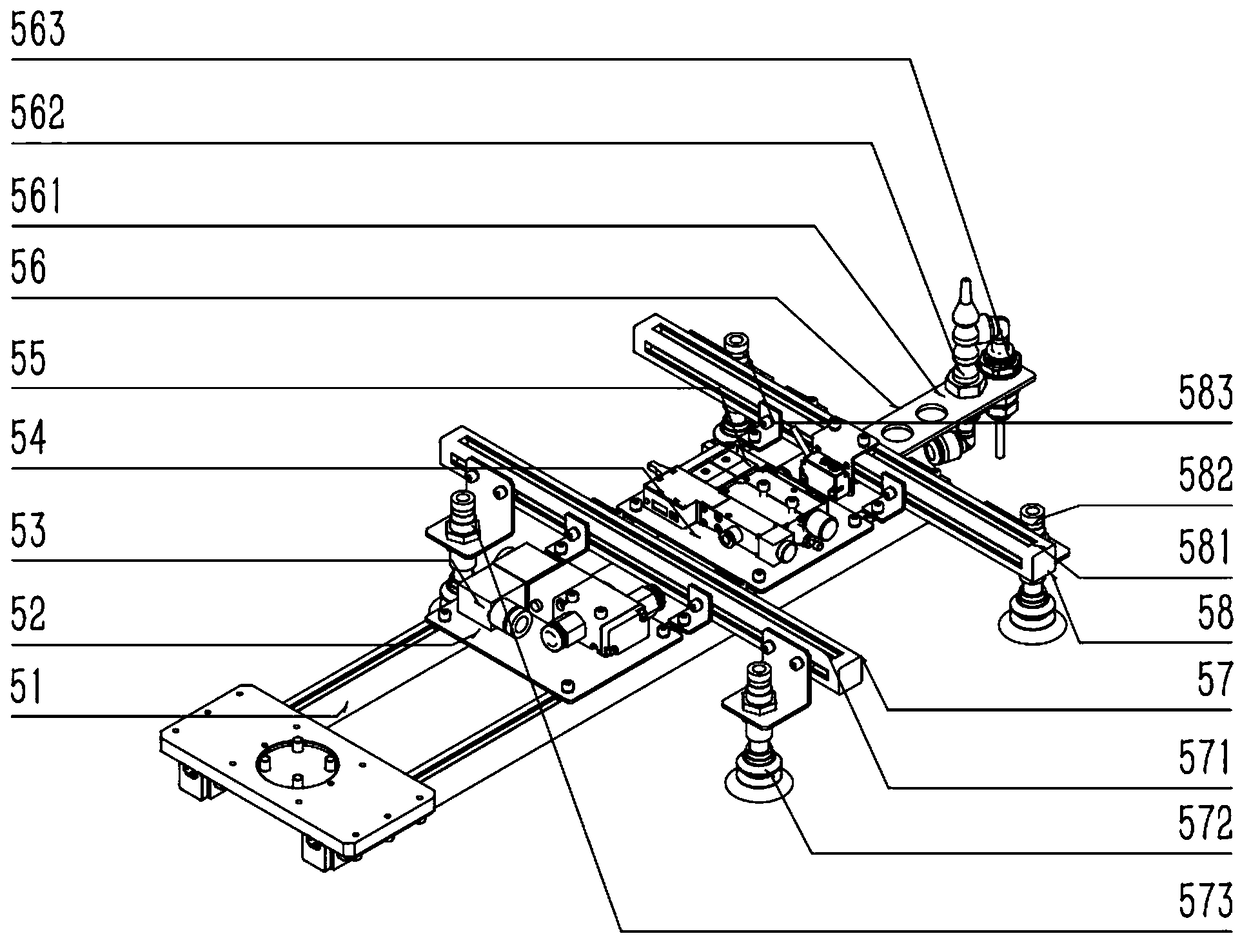

[0025] Such as figure 1 , The safety fence (3) is connected with the two sides of the stamping die library (9), and the safety fence (3) and the stamping die library (9) define the space range of the flexible working space. The punch (1), the laser cutting machine (2), the articulated industrial robot (4), the robot gripper (5) and the vision camera (6) are arranged inside the working space, the discharge conveyor line (7) and the input The material conveying line (8) extends through the working space and is used for docking with the upper process and the next process in the production line. The industrial robot (4) is connected with the discharging c...

Embodiment 2

[0036] Such as Figure 4 As shown, Embodiment 2 is suitable for methods that do not need to be connected to other production lines. In Example 2, an aggregater (10) and a feeder (11) are used instead of the discharge conveyor line (7) and the feed conveyor line (8) described in Example 1, which are used in the production line and the upper and lower channels Process docking, other components and their structures are the same as in Example 1.

[0037] The aggregater (10) and the feeder (11) each have two independent stations to facilitate the loading and unloading of the system during operation; the distance between the limit stops of each independent station can be driven by pneumatic or The electric drive realizes distance adjustment to suit the storage of stamping products of different specifications. When changing the production to replace the stamping die, the system will read the corresponding product size of the die and automatically adjust the distance between the indepe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com