Automatic automobile plate punching equipment and control circuit thereof

A technology for stamping equipment and sheet materials, which is applied in the field of automatic sheet metal stamping equipment and its control circuit for automobiles, which can solve problems such as the ineffective connection between the stamping area and the conveyor belt, affecting the stamping efficiency of automobile sheets, and damage to punches and dies, etc., to improve The effect of improving the service life, improving the stamping efficiency, and improving the stamping effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

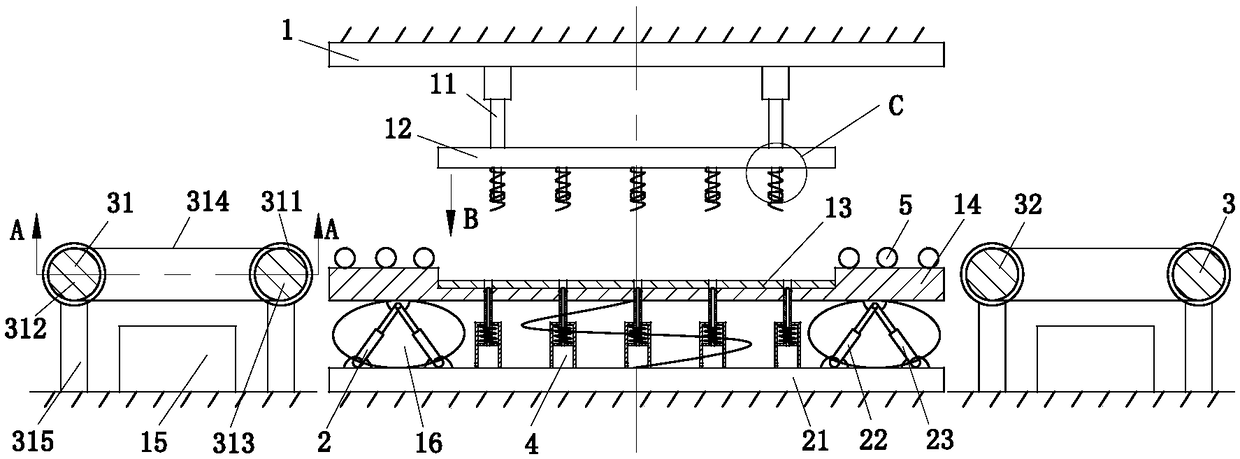

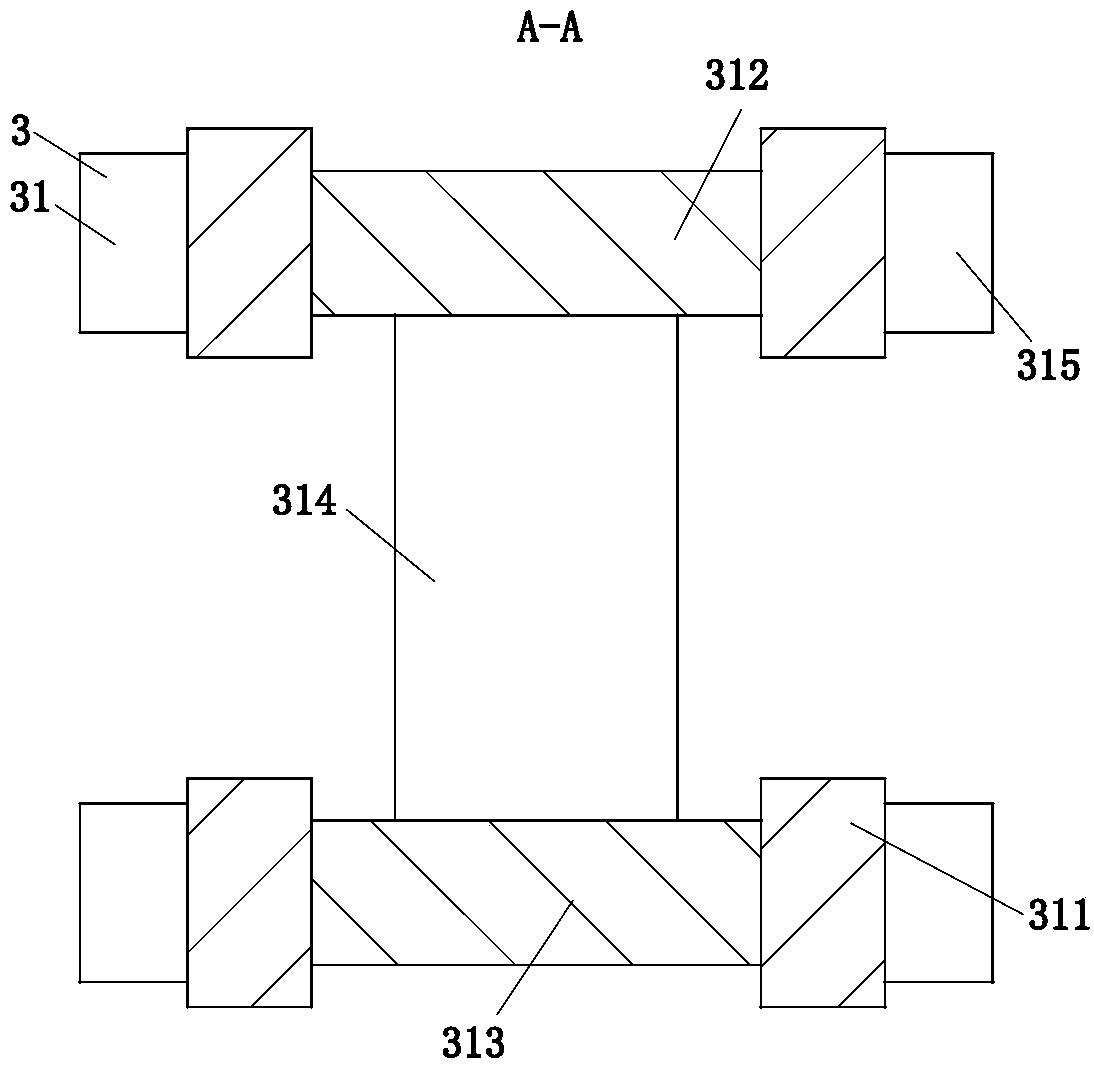

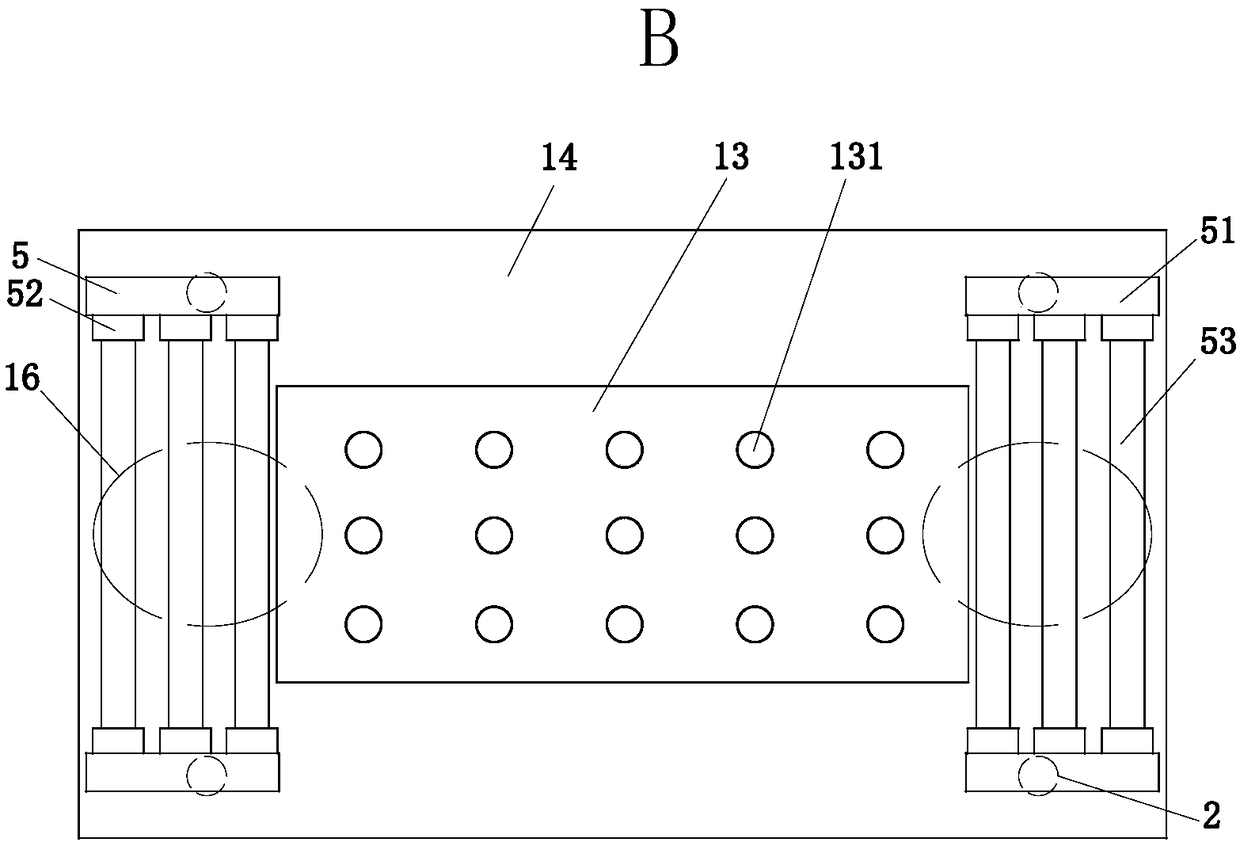

Method used

Image

Examples

Embodiment approach

[0050] As an embodiment of the present invention, the outer ring of the electromagnet 61 is coated with a layer of anti-skid material, and the anti-skid material is used to increase the friction between the automobile plate and the electromagnet 61 . During the process that the automobile sheet is pushed out by the ejector rod 4, the automobile sheet can be quickly transported from the die 13 to the transition unit 5, thereby improving the stamping efficiency of the automobile sheet.

[0051] A control circuit for automatic stamping equipment for automobile sheets, including a control unit for controlling the operation of the stamping equipment, and including

[0052] The electric unit includes No. 1 solenoid valve and No. 2 solenoid valve. The No. 1 solenoid valve and No. 2 solenoid valve are both connected to the control unit. The No. 1 solenoid valve is used to control the operation of the hydraulic pump, which provides power for the telescopic hydraulic cylinder 11 , the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com