Outer plate post positioning baffle of chain assembly machine

A technology of outer chain plate and rear positioning, which is applied in the direction of metal chains, etc., and can solve the problem of not being able to shift to the right

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

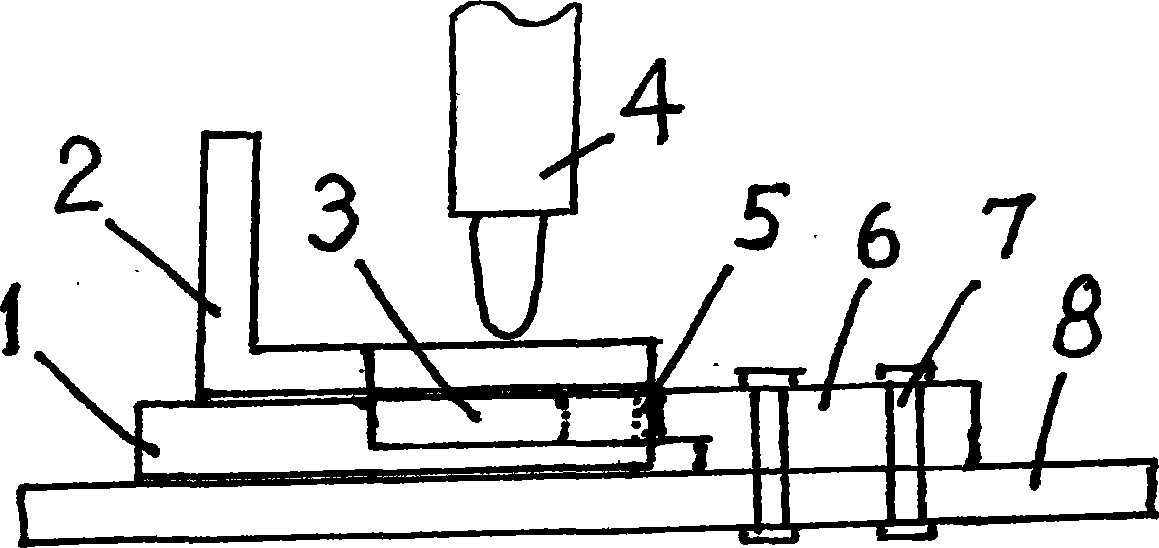

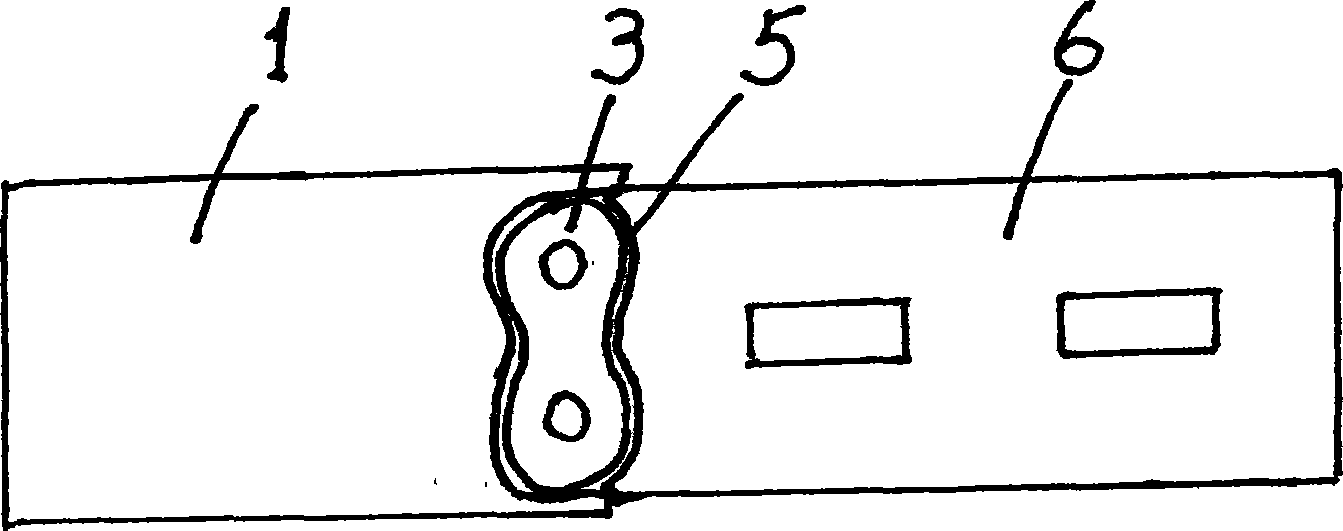

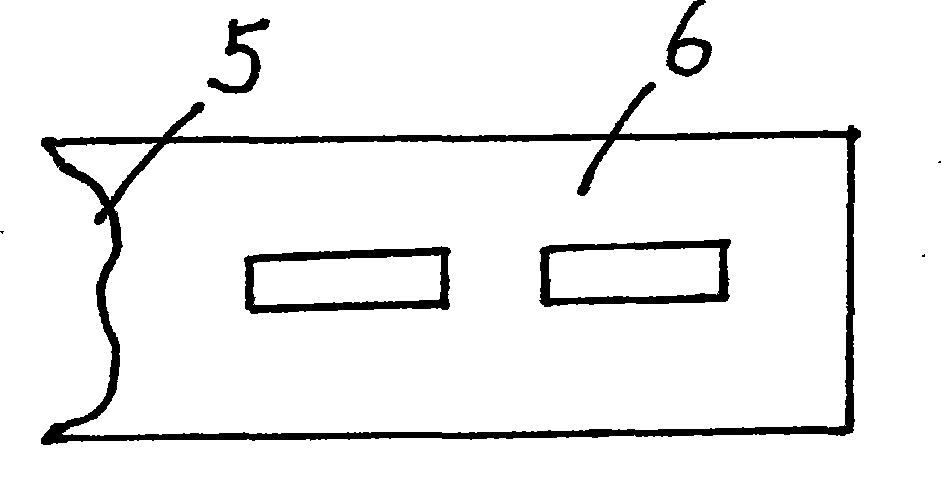

[0010] As shown in each figure: when the outer chain plate 3 is sent to the stamped position by the feeding plate 1, there is an outer chain plate pressing piece 2 in the middle below the two stamping heads 4. The outer chain plate pressing piece 2 is the outer chain plate 3 below. A feeding plate 1 is arranged in front of the outer chain plate 3 . The left side of the outer chain plate 3 and the front and rear sides are all blocked by the feeding plate 1. It is characterized in that a rear positioning baffle plate 6 is set on the right side of the outer chain plate 3 . The rear positioning baffle 6 is fixed on the platform 8 by bolts 7 . The upper plane of the rear positioning baffle plate 6 is flat with the plane on the outer chain plate. The front end of the rear positioning baffle plate 6 is a semicircular concave block 5 with both sides protruding slightly forward and inwardly recessed in the middle. The arc shape of the semicircular concave block 5 is similar to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com