A Progressive Die for Double Hole Shielding Cover

A shielding and progressive technology, applied in the field of double-hole shielding progressive molds, can solve the problems of low production efficiency of shielding, complex shielding design, high design and manufacturing cost, and achieve low defective rate, high production efficiency, The effect of reducing labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

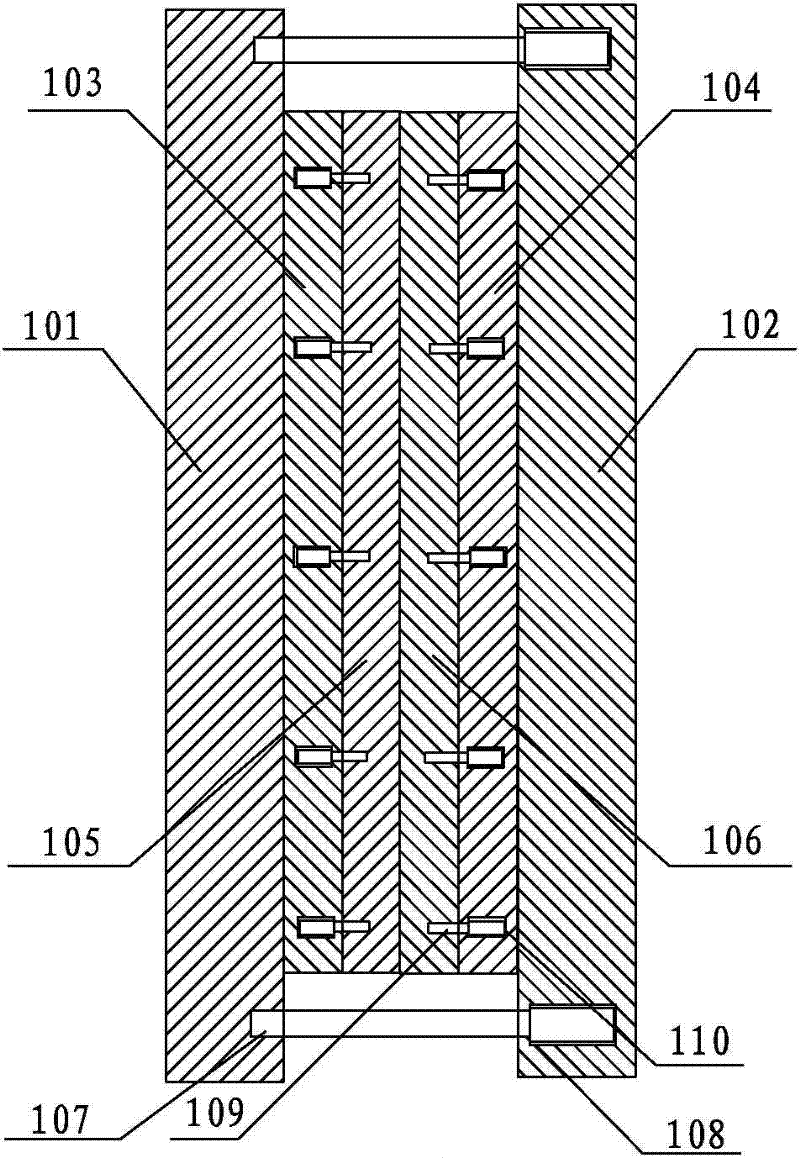

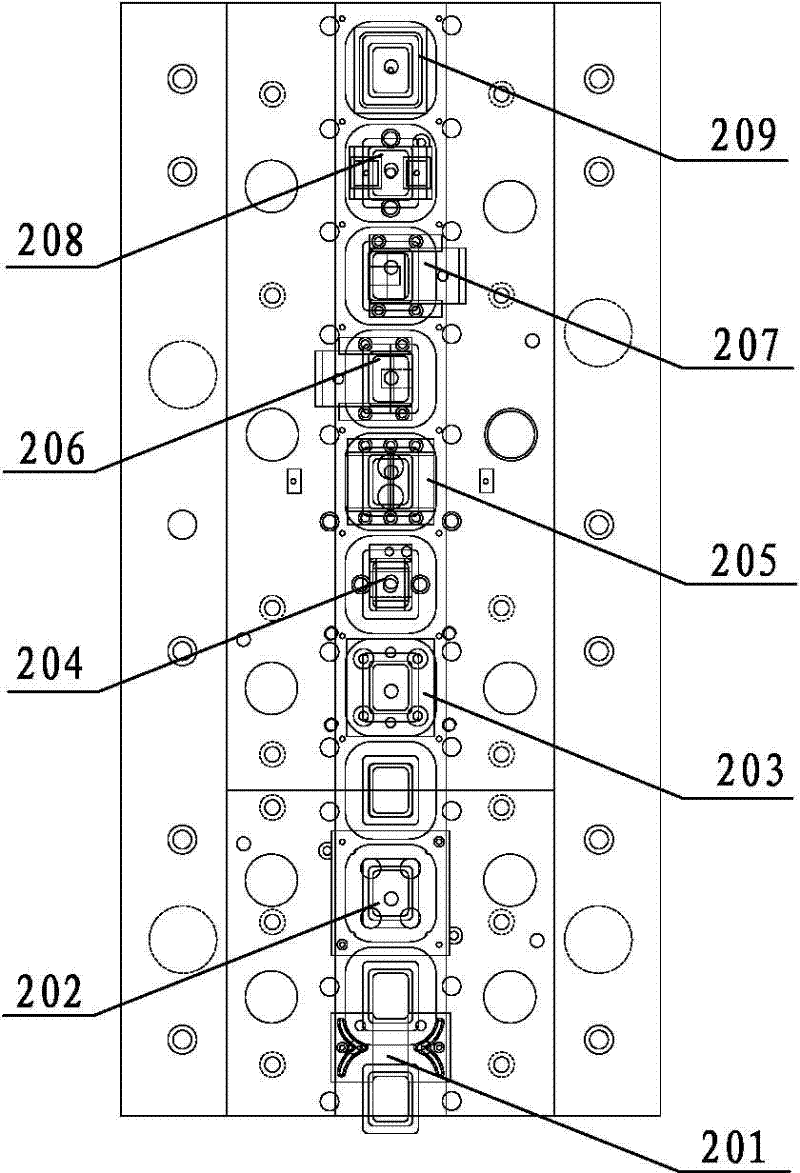

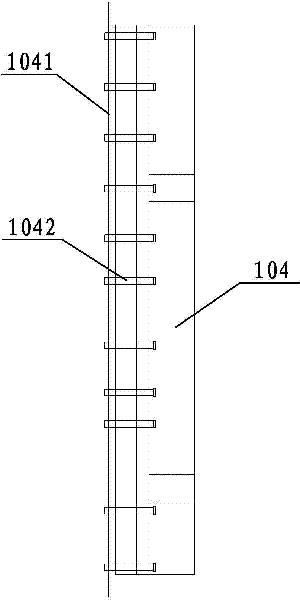

[0073] A kind of double-hole shield progressive mold of the present invention such as Figure 1-13 As shown, it includes an upper mold base 101, an upper mold 103, a stripper plate, a lower mold 104 and a lower mold base 102. The special feature is that the upper mold 103, the stripper plate and the lower mold 104 are assembled in sequence to form a punching guide hole station 201, half-cutting station 202, stretching station 203, double-sided punching station 204, double-sided hole flanging station 205, first flanging flattening station 206, second flanging flattening station 207, punching side notch station 208, punching down shielding cover station 209.

[0074] The double-sided punching station 204 punches holes from the outside to the inside of the stretched part, including the punching and stripping sliders 401 arranged on both sides of the upper die 103, and the punching and stripping slides on both sides of the stripper plate. Slide block 402, punching and stripping s...

Embodiment 2

[0079] A double-hole shield progressive die of the present invention has the same main structure as that of the above-mentioned embodiment 1, and the difference lies in:

[0080] The double-side hole flanging station 205 flangs the drawn part from the outside to the inside, including the three-stage punch 501 of the inner slide block of the flanging lower die on both sides of the upper die 103 and the flanging and stripping slide block punch 502, The flanging and stripping slider punch 502 is arranged on the inner side of the third-stage punching 501 of the slider in the flanging lower mold;

[0081] The secondary punch 503 of the inner slide block of the flanging lower die which is arranged on both sides of the lower die 104, the inner slide block of the flanging lower die which is arranged in the middle of the lower die 104, and the bottom of the inner slide block of the flanging lower die The slide block resetting device 508, the third-stage punch 501 of the inner slider of...

Embodiment 3

[0090] A double-hole shield progressive die of the present invention has the same main structure as that of the above-mentioned embodiment 1, and the difference lies in:

[0091] The first flanging flattening station 206 is to flatten the flanging 302 from the inside to the outside of the drawn part, including the first flanging flattening punch 601 arranged on the upper die 103, and the first flanging arranged on the stripper plate. The flattening punching hole and the first flanging flattening block 602 arranged on the lower die 104, the first flanging flattening punch 601 passes through the first flanging flattening punching hole, the first flanging flattening block 602 is provided with The first flanging flattening block 603 , the first flanging flattening block 603 is provided with a first side hole protection protrusion 604 , and the bottom of the first flanging flattening block 602 is provided with a first reset device 605 .

[0092] During operation, the upper mold 103...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com