Method for stamping washers

A technology of gaskets and stamping heads, which is applied in the field of parts processing, can solve the problems of increasing the processing cost of internal tooth lock washers and reducing the processing efficiency of internal tooth lock washers, so as to reduce the stamping defective rate, fast transmission, and simplify the calibration steps Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in further detail below by means of specific embodiments:

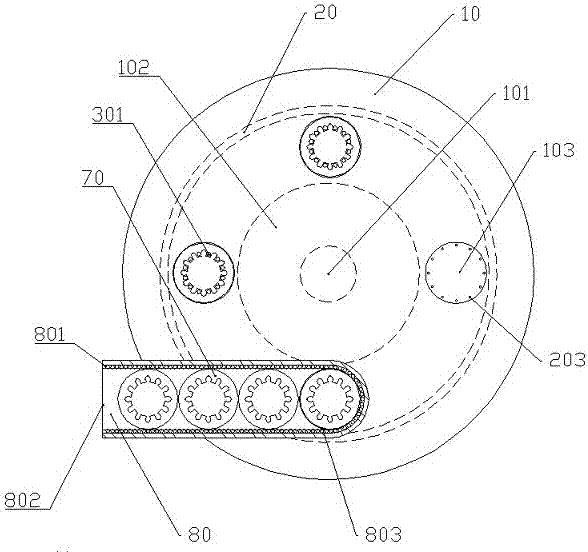

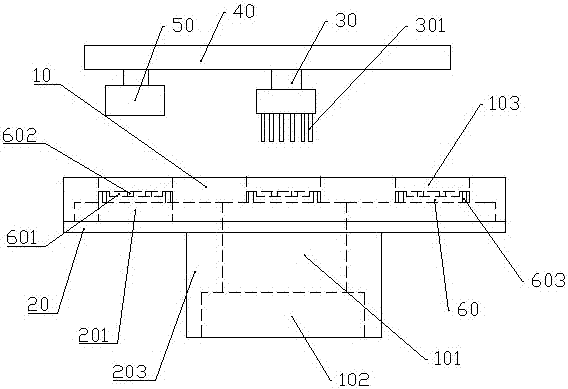

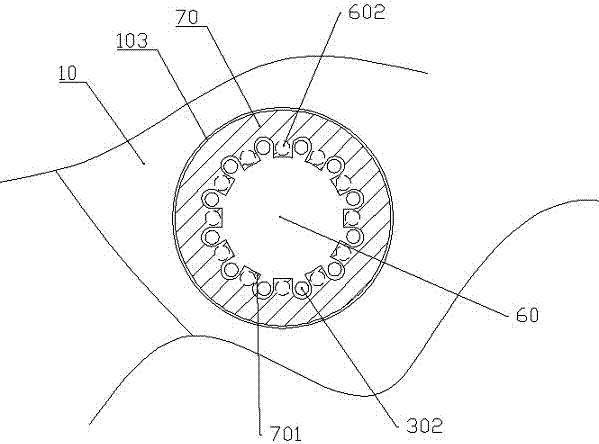

[0024] The reference signs in the accompanying drawings of the description include: turntable 10, rotating shaft 101, motor 102, processing through groove 103, fixed table 20, support block 201, spring 202, unloading rod 203, installation sleeve 204, support column 205, telescopic rod 30. Driving lever 301, laser generator 302, laser receiver 303, frame 40, stamping head 50, support table 60, groove 601, ejector rod 602, unloading hole 603, internal tooth lock washer 70, stamping part 701, transfer box 80, ball 801, feed inlet 802, discharge outlet 803,.

[0025] The stamping device in the embodiment is basically as attached figure 1 And attached figure 2 As shown: it includes a turntable 10 , a vertically arranged rotating shaft 101 , a motor 102 , a supporting mechanism, a calibration stamping mechanism and a transfer box 80 .

[0026]The turntable 10 is horizontall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com